Preparation method for low-density foam palladium material

A low-density, foam technology, applied in the field of palladium material preparation, can solve the problems of serious environmental pollution, difficulty in further reducing the bulk density of the material, low density, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

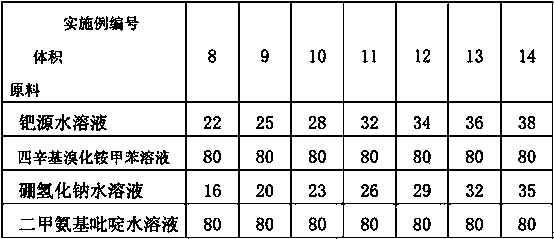

Examples

Embodiment 1

[0032] A preparation method for low-density palladium foam material, comprising the following steps:

[0033] (1) Take 0.75ml of a monodisperse PS microsphere aqueous solution with a mass fraction of 10% and a diameter of 10μm produced by Suzhou Nano Microbiology Technology Co., Ltd., disperse the PS microsphere emulsion in 7.5ml of deionized water, and add the aforementioned 10ml of nano-palladium For hydrosol, centrifuge the solution after vigorous stirring;

[0034] (2) After centrifugation, the sample is dispersed in 80ml of deionized water, 1.2ml of 0.4mol / L sodium chloropalladate aqueous solution is added, the solution is centrifuged after vigorous stirring, and the obtained sample is dispersed in 1ml of deionized water, using the aforementioned rheological casting process, The resulting suspension was molded into a polytetrafluoroethylene tube with an inner diameter of 5.0mm, and placed in a 40°C incubator to dry for 24 hours;

[0035] (3) After the sample is completel...

Embodiment 2

[0038] A preparation method for low-density palladium foam material, comprising the following steps:

[0039] (1) Take 0.75ml of monodisperse PS microsphere aqueous solution with a mass fraction of 10% and a diameter of 10 μm, disperse the PS microsphere emulsion in 7.5ml deionized water, add 10ml nano-palladium hydrosol, and centrifuge the solution after vigorous stirring separation;

[0040] (2) After centrifugation, the sample is dispersed in 80ml deionized water, and 0.4mol / L palladium chloride is added

[0041] 0.6ml of sodium bicarbonate aqueous solution, centrifuge the solution after vigorous stirring, disperse the obtained sample in 1ml of deionized water, mold the obtained suspension into a polytetrafluoroethylene tube with an inner diameter of 5.0mm, and place it in a 40°C incubator Dry for 24 hours;

[0042] (3) After the sample is completely dried, it is removed from the mold, and placed in a tube furnace for sintering, and the temperature is slowly raised to 400...

Embodiment 3

[0045] A preparation method for low-density palladium foam material, comprising the following steps:

[0046] (1) Take 0.75ml of a monodisperse PS microsphere emulsion with a mass fraction of 10% and a diameter of 1.0 μm, disperse the PS microsphere emulsion in 7.5ml of deionized water, add 10ml of nano-palladium hydrosol, and stir the solution vigorously centrifugal separation;

[0047] (2) After centrifugation, the sample is dispersed in 80ml deionized water, and 0.4mol / L palladium chloride is added

[0048] 0.5ml sodium bicarbonate aqueous solution, centrifuge the solution after vigorous stirring, disperse the obtained sample in 1ml deionized water, mold the obtained suspension into a polytetrafluoroethylene tube with an inner diameter of 5.0mm, and place it in a 40°C incubator to dry 24 hours;

[0049] (3) After the sample is completely dried, it is removed from the mold, and placed in a tube furnace for sintering, and the temperature is slowly raised to 400°C at 2°C / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com