Polyvinyl chloride-based gel polymer electrolyte as well as preparation method and application thereof

A polyvinyl chloride, gel-based technology, applied in the direction of capacitor electrolyte/absorbent, electrolytic capacitors, circuits, etc., can solve the problems of accelerated gas, gas leakage, safety hazards, etc., to overcome safety hazards and environmental pollution, excellent electrical Good chemical performance and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

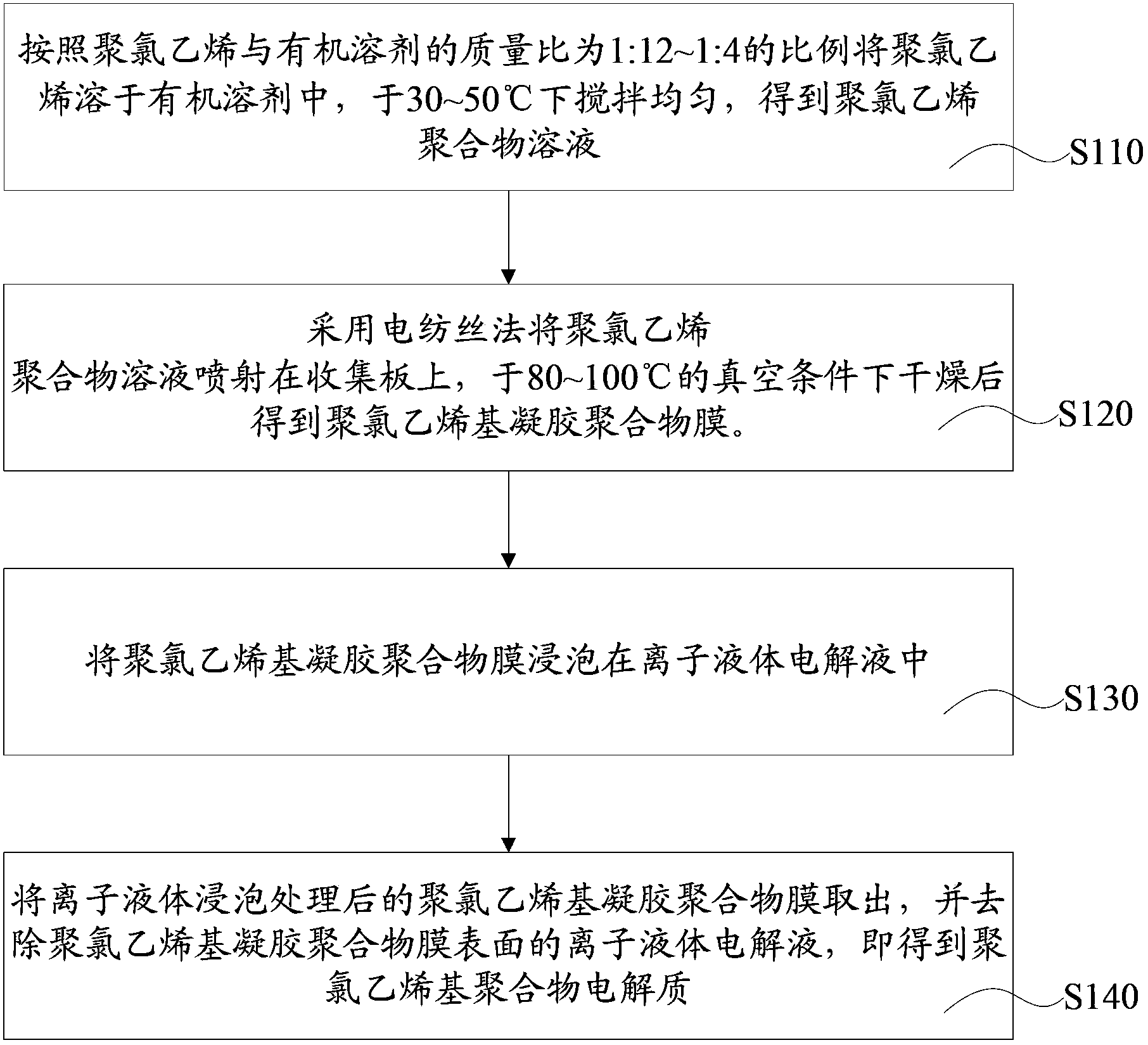

[0026] In addition, a method for preparing a polyvinyl chloride-based gel polymer electrolyte is also provided in this embodiment, such as figure 1 shown, including the following steps:

[0027] Step S110, dissolving polyvinyl chloride in an organic solvent according to the mass ratio of polyvinyl chloride to organic solvent of 1:12-1:4, stirring evenly at 30-50° C. to obtain a polyvinyl chloride polymer solution.

[0028] Among them, the molecular weight of polyvinyl chloride is 50,000~120,000.

[0029] The organic solvent is cyclohexanone, dichloroethane or tetrahydrofuran and the like.

[0030] In step S120, the polyvinyl chloride polymer solution is sprayed on the base film by electrospinning, and dried under vacuum conditions at 80-100° C. to obtain a polyvinyl chloride-based gel polymer film.

[0031] In this embodiment, the model of the electrospinning machine in the electrospinning process is BGG4-21. In the process of spraying polyvinyl chloride gel polymer on the ...

Embodiment 1

[0045] Dissolve 10 g of polyvinyl chloride with a molecular weight of 80,000 in 90 g of cyclohexanone, and stir evenly at 50° C. to obtain a polyvinyl chloride solution.

[0046] The polyvinyl chloride polymer solution is sprayed on the base film by electrospinning, the thickness of the polyvinyl chloride gel polymer film deposited on the base film is controlled to be 0.20mm, and then the polyvinyl chloride gel polymer film is cut Form a disc with a diameter of 12 mm, and dry the obtained disc at 100° C. for 36 h under a vacuum condition of 0.01 MPa. Wherein, the model of electrospinning machine used is BGG4-21, and the working parameter of electrospinning machine is: the distance between spinneret and matrix membrane is 15cm, and spinning voltage is 12KV, and the polyvinyl chloride gel polymer The flow rate is 1.0mL / h.

[0047] Soak the vacuum-dried wafer in an acetonitrile solution of 1.2 mol / L N-butyl-N-methylmorpholine tetrafluoroborate for 30 minutes; take out the soaked...

Embodiment 2

[0049] Dissolve 10 g of polyvinyl chloride with a molecular weight of 50,000 in 40 g of tetrahydrofuran, and stir evenly at 40° C. to obtain a polyvinyl chloride solution.

[0050] The polyvinyl chloride polymer solution is sprayed on the base film by electrospinning, and the thickness of the polyvinyl chloride gel polymer film deposited on the base film is controlled to be 0.10 mm, and then the polyvinyl chloride gel polymer film is cut Form a disc with a diameter of 12 mm, and dry the obtained disc at 80° C. for 12 h under a vacuum condition of 0.01 MPa. Wherein, the model of electrospinning machine used is BGG4-21, and the working parameter of electrospinning machine is: the distance between spinneret and matrix membrane is 15cm, and spinning voltage is 12KV, and the polyvinyl chloride gel polymer The flow rate is 0.5mL / h.

[0051] Soak the vacuum-dried wafers in an acetonitrile solution of 0.5 mol / L N-methoxyethyl-N-methylmorpholine tetrafluoroborate for 60 minutes; take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com