Manufacturing method for GaN epitaxy or substrate

A fabrication method and epitaxy technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as complex methods, and achieve the effects of simple process steps, strong operability, and alleviating GaN stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

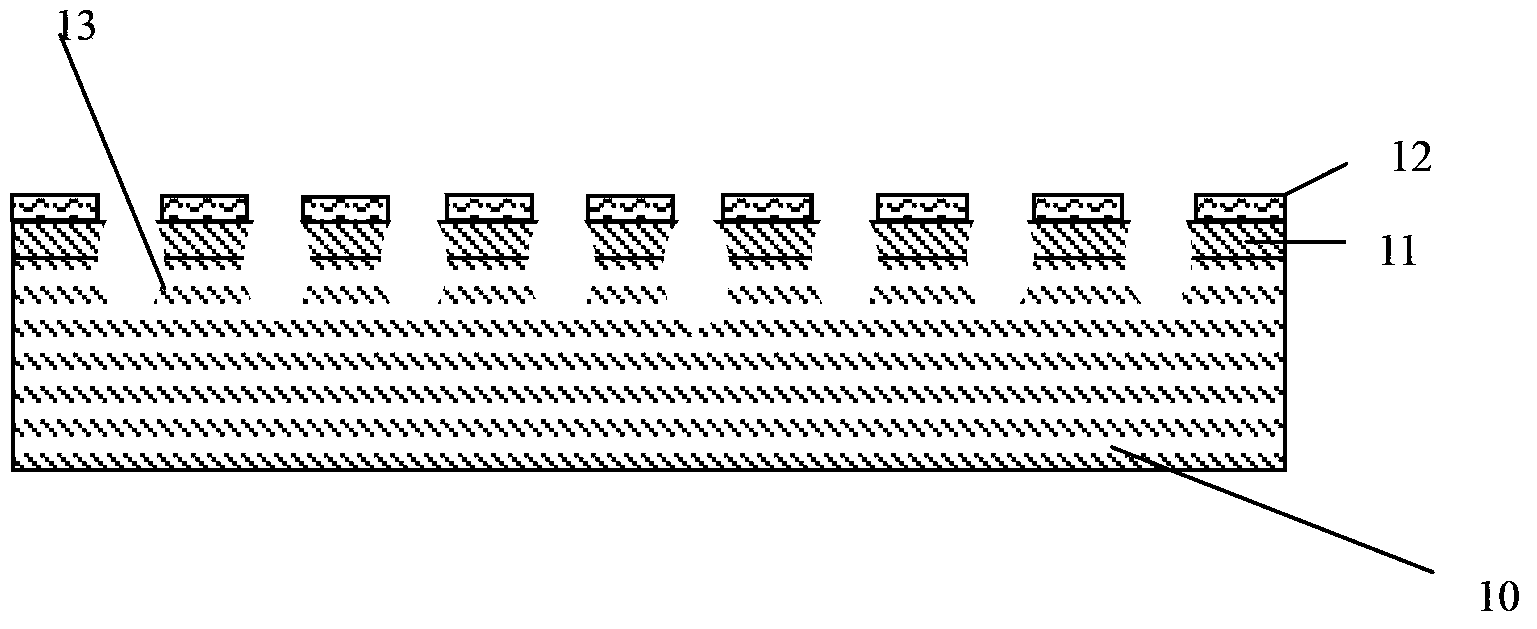

[0029] Such as Figure 1-Figure 6 As shown, a GaN epitaxial manufacturing method of the present invention mainly includes the following steps:

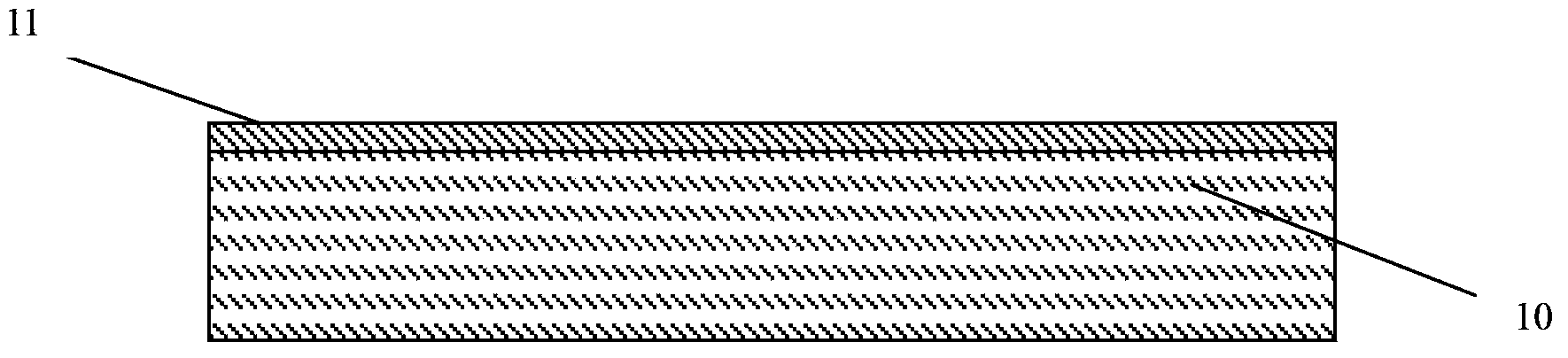

[0030] 1. Growth buffer layer 11 on silicon substrate 10, buffer layer 11 is AlN, Al 2 o 3 , GaN, AlAs, at least one of GaAs (see figure 1 ). The buffer layer 11 can be grown by MOCVD (Metal-organic Chemical Vapor Deposition, metal-organic compound chemical vapor deposition), ALD (atomic layer deposition), etc., and the thickness of the buffer layer 11 is 10-200 nm.

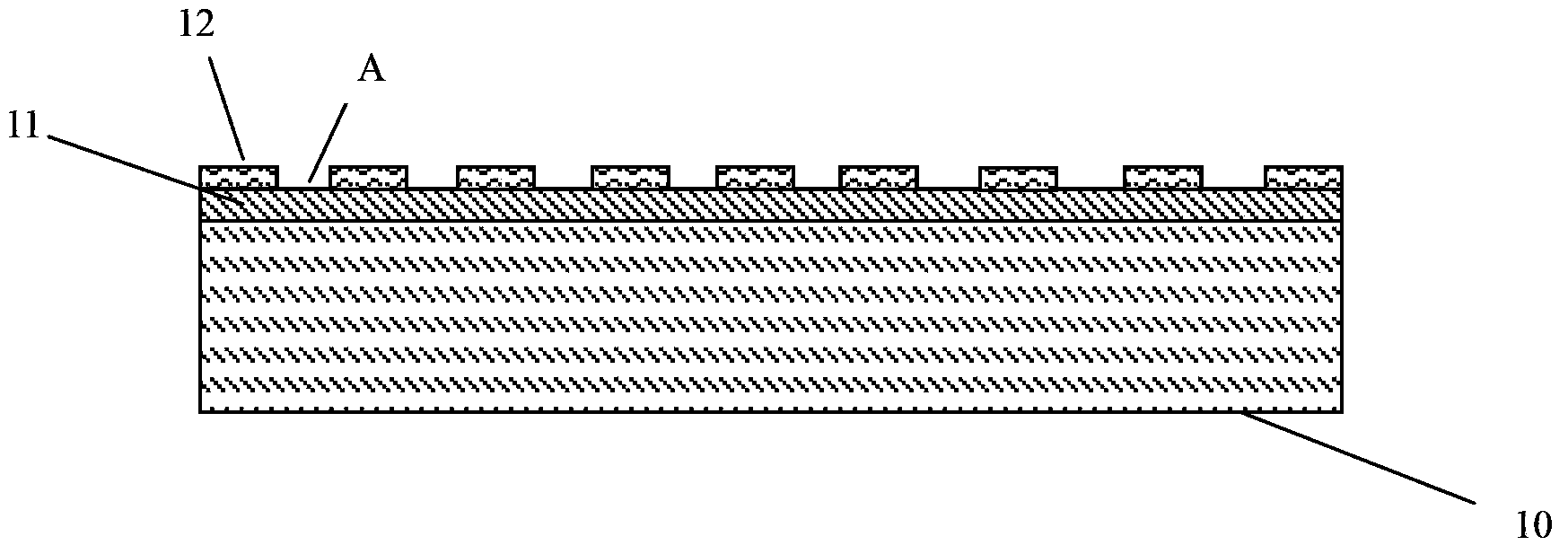

[0031] 2. The photoresist 12 is coated and exposed to form a defined pattern on the buffer layer 11: a plurality of circular areas A, the radius of each circular area A is 0.01-100 microns (in this embodiment, preferably 3 microns), The pitch is 0.1-100 microns (in this example, preferably 5 microns) (see figure 2 , Figure 7 )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com