Constant high temperature circulation NCM 523 (nickel cobalt manganese acid lithium) ternary material and preparation method thereof

A nickel-cobalt lithium manganese oxide, high-temperature cycle technology, applied to electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of small self-discharge, poor storage performance, fast decay of charge-discharge cycle capacity, etc., and achieve low cost , Large specific capacity, easy to scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

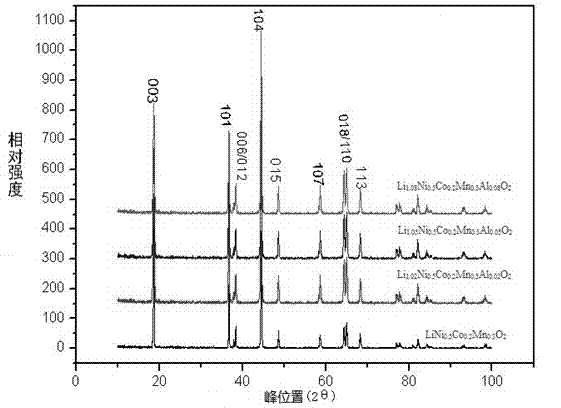

[0033] The precursor oxide (Ni 0.5 co 0.2 mn 0.3 ) 2 O, after sieving, aluminum hydroxide with an average particle size of 6 μm battery-grade lithium carbonate and an average particle size of 200 nm according to Li:Ni 0.5 co 0.2 mn 0.3 The molar ratio of :Al=1.02:1:0.02 is fully mixed by dry mixing.

[0034] The mixture obtained above was put into a sagger for compaction, heated at a constant temperature of 950° C. for 18 hours in an air atmosphere for roasting reaction, and naturally cooled for 10 hours after completion, the powder was taken out, pulverized, and sieved.

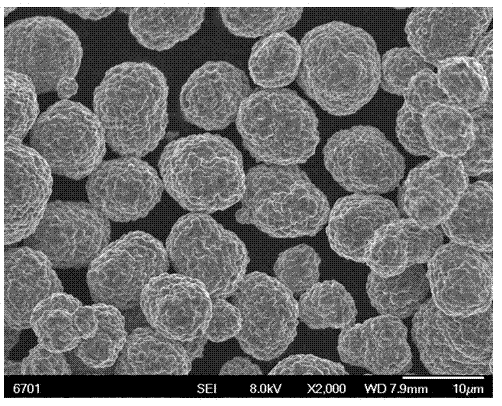

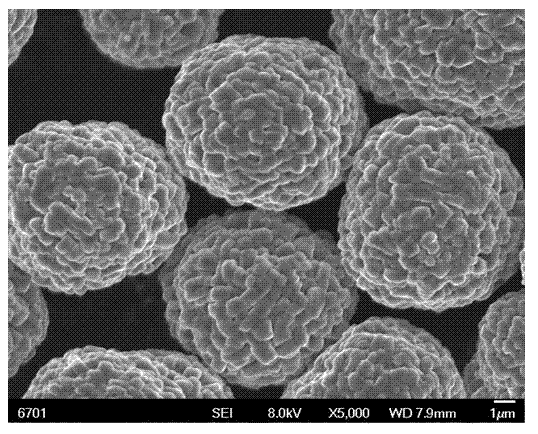

[0035] Put the powder obtained above into a sagger and smooth it, and heat it at a constant temperature of 810°C for 6 hours in the air atmosphere for sintering. After the completion, take out the powder and sieve it after natural cooling to obtain a long-term high-temperature cycle lithium cobalt manganese oxide NCM523 ternary Material Li 1.02 Ni 0.5 co 0.2 mn 0.3 al 0.02 o 2 . The specific sur...

example 2

[0038] The precursor oxide (Ni 0.5 co 0.2 mn 0.3 ) 2 O, after sieving, the aluminum oxide with an average particle size of 6 μm battery-grade lithium carbonate and an average particle size of 50 nm according to Li:Ni 0.5 co 0.2 mn 0.3 : Al = 1.05: 1: 0.05 molar ratio is fully mixed by dry mixing.

[0039] The mixture obtained above was put into a sagger for compaction, heated at a constant temperature of 930° C. for 15 hours in an air atmosphere for roasting reaction, and naturally cooled for 8 hours after completion, the powder was taken out, pulverized, and sieved.

[0040] Put the powder obtained above into a sagger and smooth it, heat it at a constant temperature of 830°C in an air atmosphere for 8 hours for roasting, and after it is naturally cooled, take out the powder and sieve it to obtain a long-term high-temperature cycle lithium cobalt manganese oxide NCM523 ternary Material Li 1.05 Ni 0.5 co 0.2 mn 0.3 al 0.05 o 2 . The specific surface area of the n...

example 3

[0043] The precursor oxide (Ni 0.5 co 0.2 mn 0.3 ) 2 O, after sieving, aluminum nitrate with an average particle size of 6 μm battery-grade lithium carbonate and an average particle size of 1.8 μm according to Li:Ni 0.5 co 0.2 mn 0.3 :Al=1.08:1:0.08 The molar ratio is fully mixed by dry mixing.

[0044] The mixture obtained above was put into a sagger for compaction, heated at a constant temperature of 910° C. for 14 hours in an air atmosphere to carry out roasting reaction, and naturally cooled for 7 hours after completion, the powder was taken out, pulverized, and sieved.

[0045] Put the powder obtained above into a sagger and smooth it, heat it at a constant temperature of 850°C in the air atmosphere for 8 hours for roasting, and then take out the powder after natural cooling and sieve to obtain a long-term high-temperature cycle lithium cobalt manganese oxide NCM523 ternary Material Li 1.08 Ni 0.5 co 0.2 mn 0.3 al 0.08 o 2 . The specific surface area of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com