Multi-arm star-shaped block polymer based electrolyte and preparation method thereof

A technology of block polymers and block copolymers, applied in hybrid capacitor electrolytes, circuits, electrical components, etc., can solve the problems of low mechanical strength and achieve the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

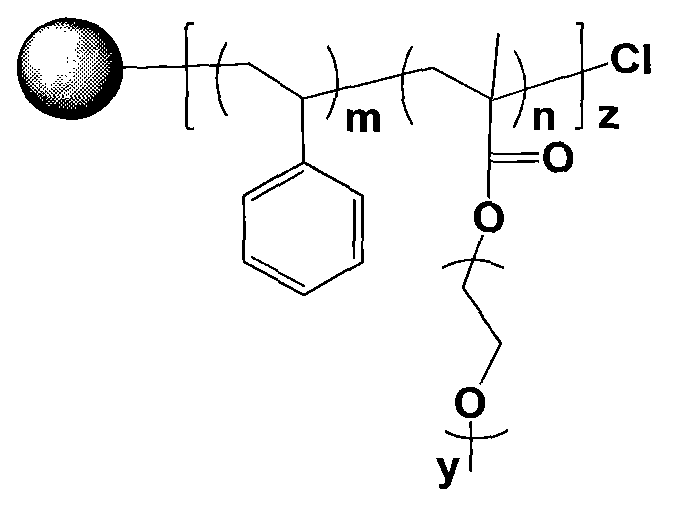

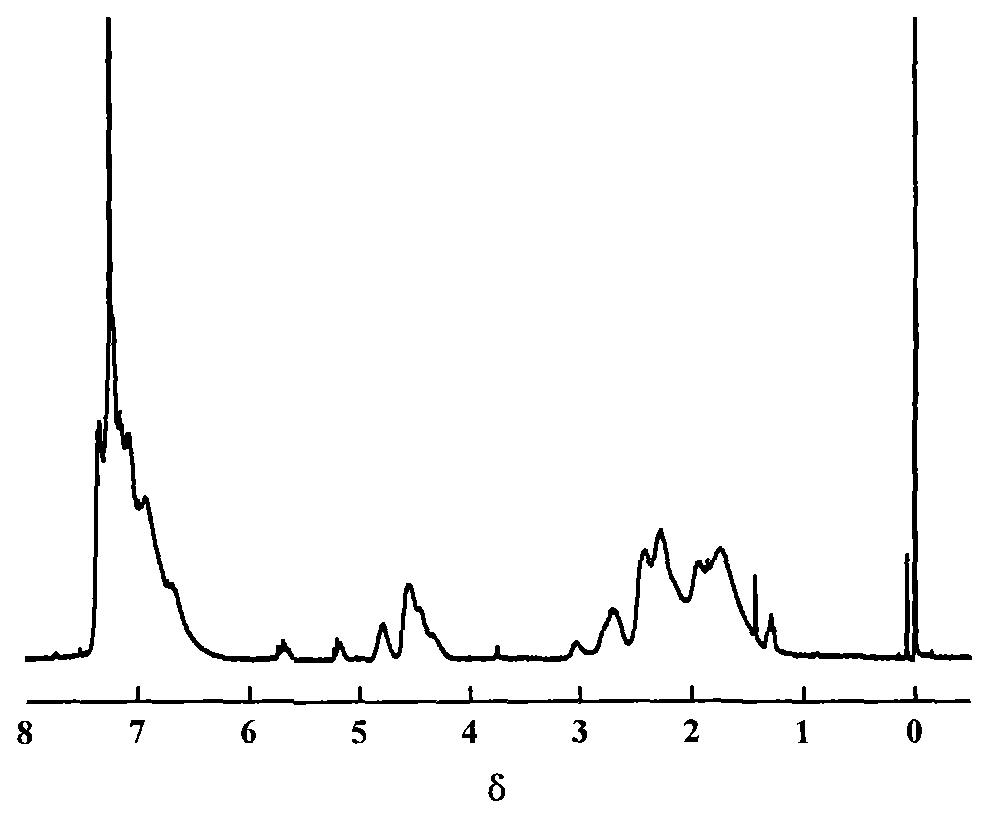

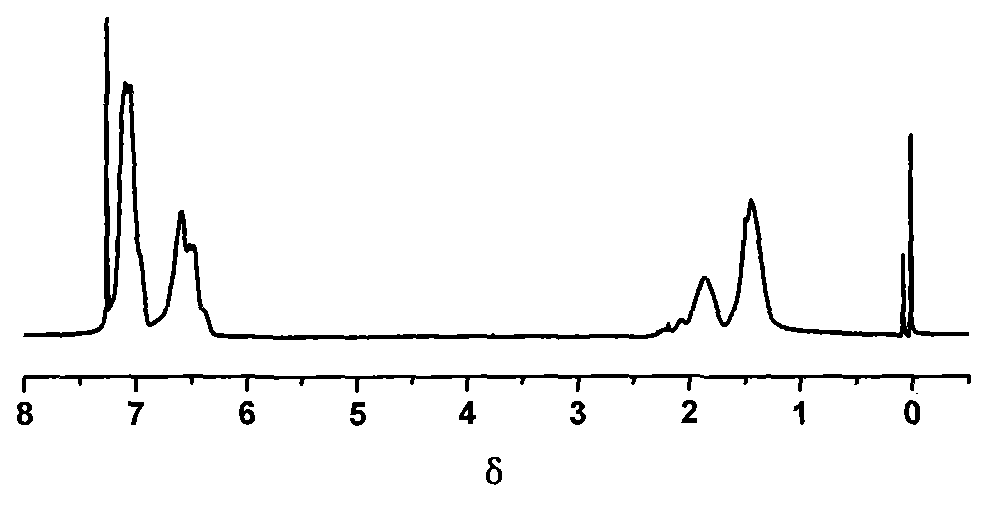

[0035] In this example, the polymerization reaction used is atom transfer radical-self-condensation vinyl polymerization (ATR-SCVP). Add 0.209g of cuprous chloride and 0.659g of 2,2'-bipyridyl into a 100mL dry polymerization bottle equipped with a magnet, and vacuumize the system with nitrogen, repeat three times, and then add 8.0mL of chlorobenzene and 2.4mL of Styrene and 3.0mL of p-chloromethylstyrene were stirred evenly, and reacted in an oil bath at 120°C under nitrogen protection for 4 hours, and then the reaction device was ventilated with air to terminate the reaction. Add tetrahydrofuran to the system to dilute, over-neutral Al 2 o 3 column to remove the catalyst, precipitate in methanol after rotary evaporation, filter with suction, and dry in a vacuum oven at 60°C for 12 hours. According to elemental analysis: C79.20%, H6.63%, Cl14.17%. The number average molecular weight measured by GPC was 6615, and the molecular weight distribution was 3.0. Each hyperbranched...

Embodiment 2

[0037]In this example, the polymerization reaction used is atom transfer radical-self-condensation vinyl polymerization (ATR-SCVP). Add 0.300g of cuprous bromide and 0.660g of 2,2'-bipyridyl into a 100mL dry polymerization bottle equipped with a magnet, and vacuumize the system with nitrogen, repeat three times, then add 8.0mL of chlorobenzene and 2.5mL of Methyl methacrylate and 3.5mL 2-(2-bromopropionyloxy)ethyl acrylate were stirred evenly, and reacted in an oil bath at 100°C under nitrogen protection for 4 hours, and then the reaction device was ventilated with air to terminate the reaction. Add tetrahydrofuran to the system to dilute, over-neutral Al 2 o 3 column to remove the catalyst, precipitate in methanol after rotary evaporation, filter with suction, and dry in a vacuum oven at 60°C for 12 hours. According to elemental analysis: C44.20%, H6.00%, O27.18, Br22.62%. The number average molecular weight measured by GPC was 7235, and the molecular weight distribution w...

Embodiment 3

[0039] Add 0.5g of the hyperbranched polymer prepared in Example 1, 0.1g of cuprous chloride, 40mL of chlorobenzene, and 46mL of styrene into a 250mL dry two-necked bottle equipped with a magnet, and cycle 3 times through freezing-vacuumizing-thawing Afterwards, 0.21 mL of pentamethyldiethylenetriamine was added with a syringe. After stirring evenly, place it in an oil bath at 120°C. After reacting for 150 minutes, pass air to terminate the reaction, and add THF to dilute. Over neutral Al 2 o 3 column to remove the catalyst, precipitate in methanol after rotary evaporation, filter with suction, and dry in a vacuum oven at 60°C for 12 hours. The number average molecular weight measured by GPC is 30055, and the number m of styrene structural units in the arms is 54.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com