Preparation technology of fruit and vegetable fresh-keeping agent

A technology of fruit and vegetable fresh-keeping agent and preparation process, which is applied in the direction of fruit and vegetable fresh-keeping, food preservation, food processing, etc., can solve the problems of increasing raw material cost and poor fresh-keeping effect of the fresh-keeping agent, and achieve saving of raw material cost, good fresh-keeping effect, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Pretreatment: Remove the residual meat and wash the shrimp and crab shells, add them to the hydrogen chloride solution with a concentration of 5% and soak for 9 hours, and keep stirring during the soaking process;

[0016] (2) Pickling and decalcification: Take out the carapace soaked in step (1), wash until neutral, add 8% potassium hydroxide solution, heat to 89°C, and stir for 4 hours, then the carapace after acid-base treatment Wash to neutral;

[0017] (3) Extraction of chitin: add 1% potassium permanganate and sodium bisulfate solution to the chitin water prepared in step (2), use a frequency-modulated vibrating rinsing machine, rinse for 55 minutes, wash and dry, and obtain white Solid product chitin;

[0018] (4) Concentrated alkali deacetylation: Take the dried chitin prepared in step (3), add 40% sodium hydroxide solution, soak it, and then use a fast aluminum rod heating furnace to rapidly heat up to 100 ° C, continuously After stirring and keeping warm...

Embodiment 2

[0020] Embodiment 2: all the other are the same as Example 1, the difference is that in the step (1), the concentration of the sodium hydroxide solution selected is 6%, and the soaking time is 10h; in the step (2), the selected The concentration of sodium hydroxide solution is 9%, and the heating temperature is 92°C; in the step (3), the rinsing time is controlled to be 60min; in the step (4), the concentration of the selected sodium hydroxide solution is 45%, and the control The holding time is 8h.

Embodiment 3

[0021] Embodiment 3: all the other are the same as Example 1, the difference is that in the step (1), the concentration of the sodium hydroxide solution selected is 7%, and the soaking time is 10h; in the step (2), the selected The concentration of the sodium hydroxide solution is 10%, and the heating temperature is 96°C; in the step (3), the rinsing time is controlled to be 65min; in the step (4), the concentration of the selected sodium hydroxide solution is 50%, Control heat preservation time is 9h.

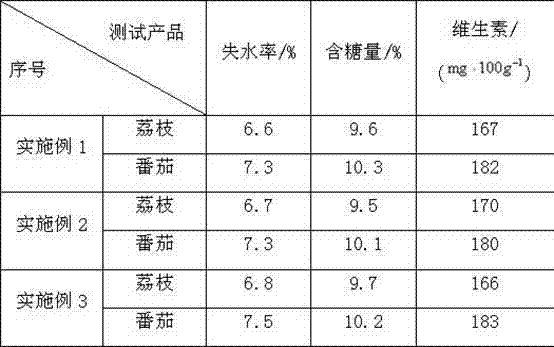

[0022] After the above process steps, the chitosan acetic acid solution with a concentration of 2% was taken out to preserve freshness of lychees and tomatoes, and the water loss rate, total sugar content and vitamin C content were measured after preservation for 20 days. The results are as follows:

[0023]

[0024] It can be seen from the above data that after the preservative prepared by this preparation method is coated on fruits and vegetables, the water loss rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com