A kind of anthraquinone organic compound, its preparation method and its application

A technology of organic compounds and anthraquinones, applied in the field of fine chemicals, can solve unsatisfactory problems, achieve the effect of accelerating delignification, reducing cooking energy consumption, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

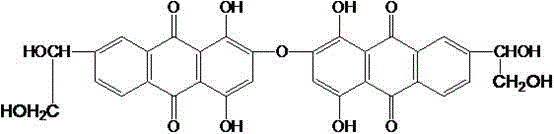

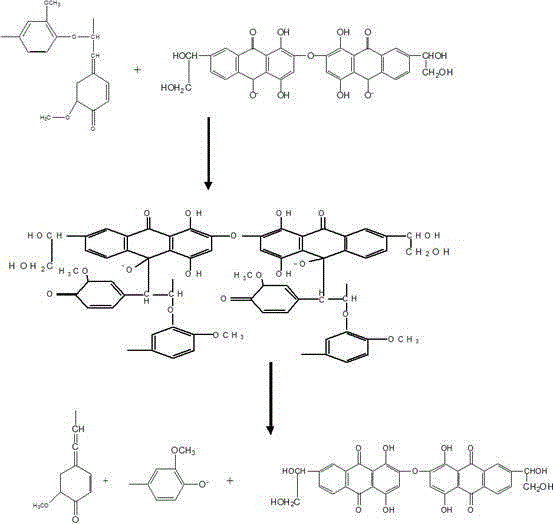

Method used

Image

Examples

preparation Embodiment 1

[0031] 72.8 g of anthraquinone was used, and 54 g of acetophenone was added for emulsification. During the emulsification process, an electromagnetic stirring rod was used to stir at a speed of 500 r / min until it was viscous and uniform. Then 101g of potassium nitrate and 28g of sodium hydroxide are added to the emulsified emulsion. When the oil bath is heated to 80°C, 18.6g of ethylene glycol and 5.46g of vanadium pentoxide catalyst are added, and the oil bath is heated to 120°C. At this time, the stirring speed was 1200r / min; the reactant was refluxed for 1.5h, and the temperature was kept at 110°C-125°C. The reaction was terminated by recrystallization with n-hexane-ethanol (V:V=1:5), and 46.05 g of light yellow crystals were obtained.

preparation Embodiment 2

[0033] 52 g of anthraquinone was used, and 36 g of acetophenone was added for emulsification. During the emulsification process, an electromagnetic stirring bar was used to stir at a speed of 500 r / min until it was viscous and uniform. Then add 80.8 g of potassium nitrate and 17.13 g of sodium hydroxide into the emulsified emulsion, add 11.44 g of ethylene glycol and 3.64 g of vanadium pentoxide catalyst when the oil bath is heated to 80 ° C, and continue to heat the oil bath to 120 ° C , the stirring speed at this time was 1200r / min; the reactant was refluxed for 1.5h, and the temperature was kept at 110°C-125°C. After the reaction was terminated, recrystallization was carried out with n-hexane-ethanol (V:V=1:5), and 36.26 g of light yellow crystals were obtained.

[0034] From Preparation Examples 1 and 2, it can be concluded that within the specified range, the ratio of raw materials is mainly affecting the yield of the synthesized catalyst, and the most suitable yield can ...

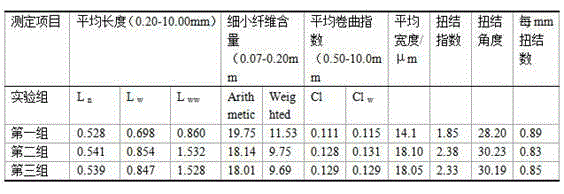

experiment example 1

[0036] Using the cooking catalytic protector obtained in Preparation Example 1 and Preparation Example 2 of the present invention and traditional anthraquinone to cook two groups of fast-growing poplar kraft pulp respectively.

[0037] The ZQSL 15L electric heating rotary cooking pot used for cooking.

[0038] The cooking conditions are set as follows: ① 1000g of fast-growing poplar wood chips, 156g of sodium oxide (the amount of alkali used is 20%, and NaOH is used in this patent), 44g of sodium sulfide (the degree of sulfide is 22%), the liquid ratio is 1:5, and the highest cooking temperature is 168 ℃, keep warm for 2h, and use 7.5g of anthraquinone. ②1000g of fast-growing poplar wood chips, 156g of sodium hydroxide (the amount of alkali used is 20%, and NaOH is used in this patent), 44g of sodium sulfide (degree of sulfide 22%), liquid ratio 1:5, maximum cooking temperature of 168°C, heat preservation for 2h . Preparation Example 1 of the present invention The amount of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com