Preparation method of (S)-4-hydroxy-2-oxo-1-pyrrolidineacetamide

A technology for pyrrolidineacetamide and hydroxyl, which is applied in the field of preparation of -4-hydroxy-2-oxo-1-pyrrolidineacetamide, and can solve the problems of increasing reaction steps, low synthesis yield, and decreased total yield , to achieve the effect of short cycle, low pollution and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

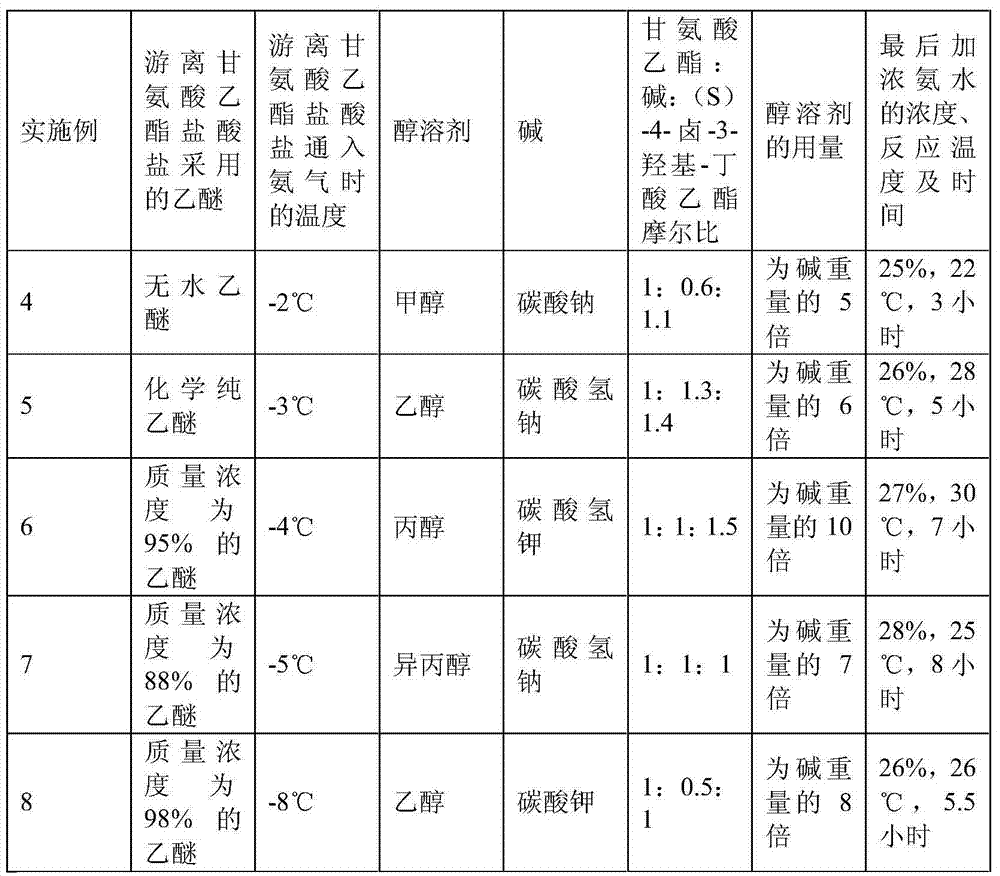

Examples

Embodiment 1

[0025] The preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidineacetamide is carried out as follows:

[0026] 1. Preparation of crude product:

[0027] (a) Add 139.6 g of ethyl glycine hydrochloride to 1,300 ml of anhydrous ether, cool to -2°C and blow in 22.1 g of ammonia gas to dissociate ethyl glycine hydrochloride into ethyl glycine, wherein ethyl glycine hydrochloride Salt: anhydrous ether: 1mol of ammonia: 1300m1: 1.3mol;

[0028] (b) Add absolute ethanol 672ml, sodium bicarbonate 84.0g, dropwise (S)-4-chloro-3-hydroxyl-butyric acid ethyl ester 250.0g in the above-mentioned product, and described dropping time is 2.5 hours, in React at pH 8.2 and temperature 66°C for 28 hours;

[0029] (c) Filtrate, fully wash the filtrate with ethanol, concentrate, dissolve the concentrate in water, add ethyl acetate 7 times the weight of the filtrate to extract, concentrate the water phase, and separate by column chromatography; the final mass percentage concentration is 26% Aque...

Embodiment 2

[0036] The preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidineacetamide is carried out as follows:

[0037] 1. Preparation of crude product:

[0038] (a) Add glycine ethyl ester hydrochloride to anhydrous ether, cool to 1°C and pass through ammonia gas to dissociate glycine ethyl ester hydrochloride into glycine ethyl ester, wherein glycine ethyl ester hydrochloride: anhydrous ether: Ammonia is 1mol: 1395ml: 1.5mol;

[0039] (b) Add anhydrous methanol, sodium carbonate, (S)-4-iodo-3-hydroxy-butyric acid ethyl ester to the above product, and react for 30 hours at a pH of 8 and a temperature of 70°C;

[0040] (c) Filtrate, fully wash the filtrate with ethanol, concentrate, dissolve the concentrate in water, then add 6 times the weight of the filtrate in dichloromethane for extraction, concentrate the water phase, and separate by column chromatography; finally add a mass percentage concentration of 25% Aqueous ammonia was reacted at 20° C. for 5 hours to obtain the crude p...

Embodiment 3

[0046] The preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidineacetamide is carried out as follows:

[0047] 1. Preparation of crude product:

[0048] (a) ethyl glycine hydrochloride is suspended in chemically pure ether, then feed ammonia to make ethyl glycine hydrochloride free into ethyl glycine;

[0049] (b) Add absolute ethanol, sodium bicarbonate, dropwise (S)-4-bromo-3-hydroxy-butyric acid ethyl ester to the above product;

[0050] (c) Then filter, fully wash the filtrate with ethanol, concentrate, dissolve the concentrate in water, then add 4 times the weight of the filtrate in chloroform for extraction, concentrate and separate the water phase; finally add concentrated ammonia water and react at 25°C for 6 hours to prepare Obtain the crude product of (S)-4-hydroxy-2-oxo-1-pyrrolidineacetamide;

[0051] 2. Purification of crude product:

[0052] (a) dissolve the above-mentioned crude product with water, pass through 732# strongly acidic cation exchange resin, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com