Noble metal/polymer microsphere Janus particles and preparation method thereof

A polymer and precious metal technology, applied in the field of precious metal/polymer microsphere Janus particles and their preparation, can solve the problems of complex preparation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of core-shell polymer microspheres

[0023] Dissolve 50 mg of isoalcohol diester maleate in 40 mL of deionized water, stir mechanically for 1 hour, add 2 g of styrene monomer, nitrogen, continue stirring for 1 hour, add 20 mg of potassium persulfate and raise the temperature to 65 ° C for 24 hours to obtain a nucleus- Shell-structured polymer microsphere emulsion.

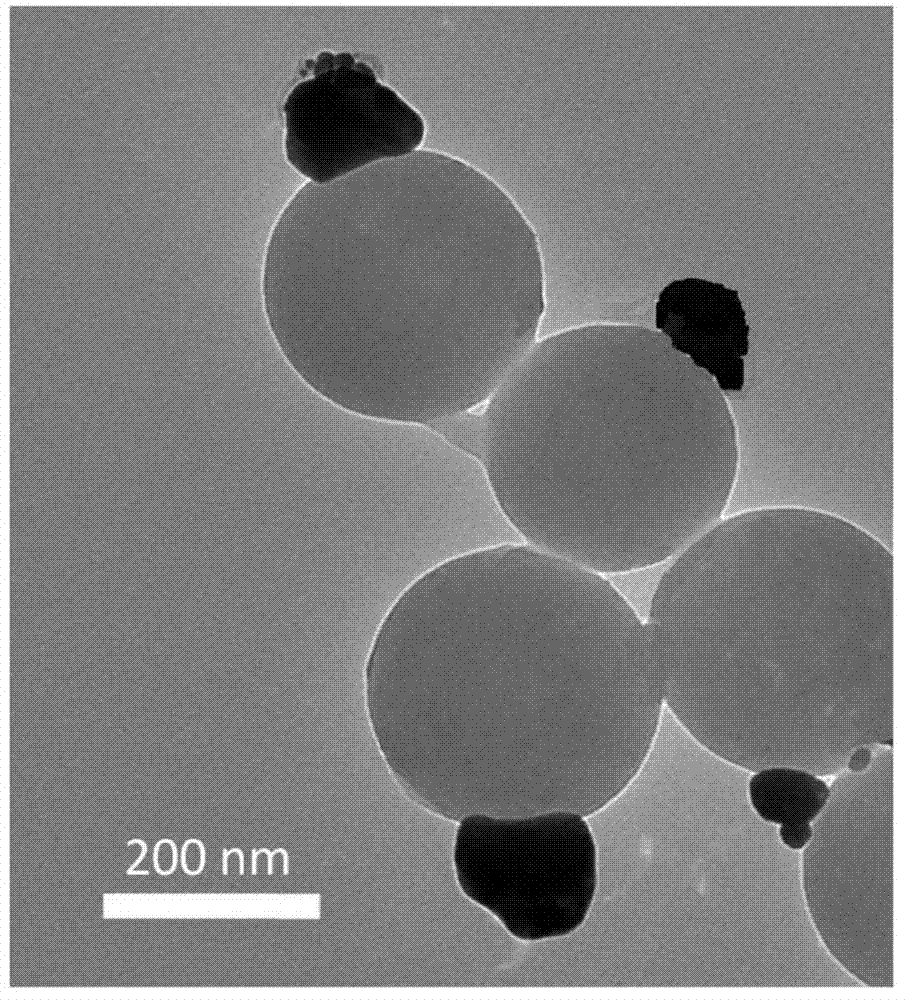

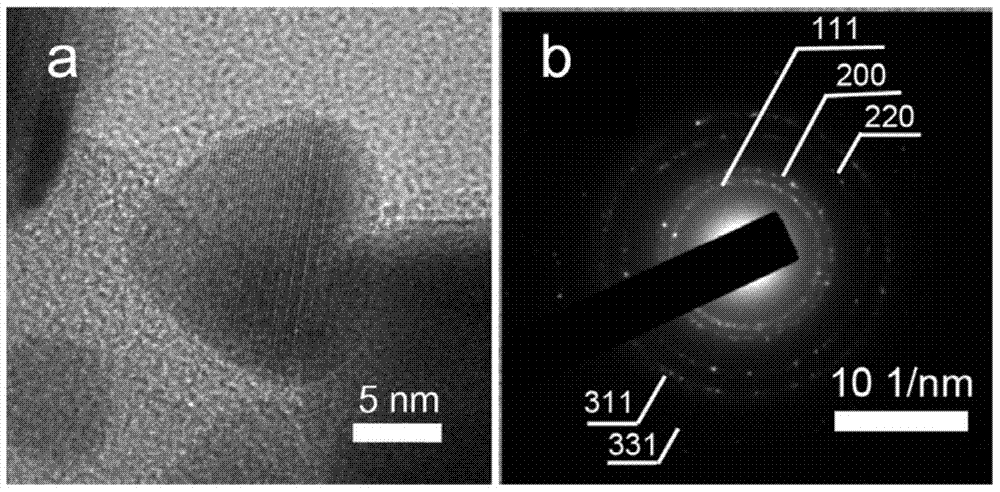

[0024] (2) Preparation of noble metal / polymer microsphere Janus particles

[0025] Take 1mL of the polymer microsphere emulsion in step (1) and dilute it to 10mL with deionized water; add 0.2mL of chloroauric acid aqueous solution with a concentration of 10mmol / L drop by drop under stirring; add 0.2mL with a concentration of 20mmol / L after 1 hour Sodium borohydride aqueous solution, stirring at room temperature for 3 hours; adding 0.0102g of cetyltrimethylammonium bromide and 1.5mL of chloroauric acid aqueous solution with a concentration of 10mmol / L, stirring for one hour and then standing ...

Embodiment 2

[0028] (1) Preparation of core-shell polymer microspheres

[0029] With embodiment 1.

[0030] (2) Preparation of noble metal / polymer microsphere Janus particles

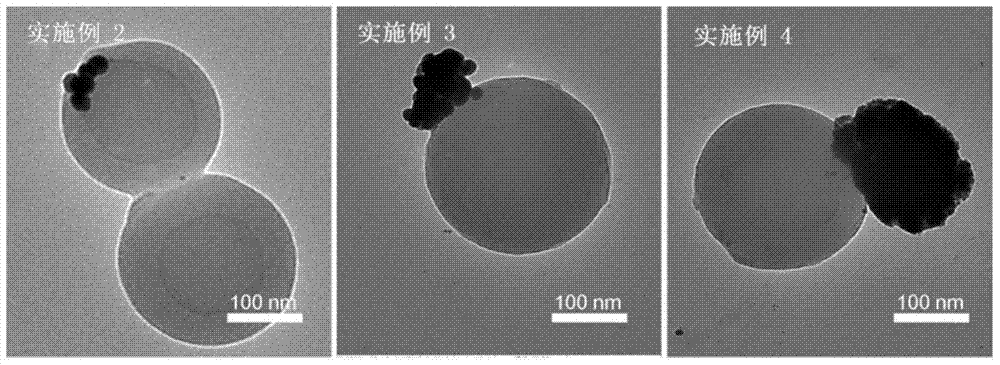

[0031] Take 1mL of the polymer microsphere emulsion in step (1) and dilute it to 10mL with deionized water; add 0.3mL of chloroauric acid aqueous solution with a concentration of 10mmol / L drop by drop under stirring; add 0.3mL of a concentration of 20mmol / L after 1 hour Sodium borohydride aqueous solution, stirring at room temperature for 3 hours; adding 0.0086g cetyltrimethylammonium bromide and 0.5mL concentration of 10mmol / L aqueous auric acid chloride solution, stirring for one hour and then standing for 4 hours to obtain precious metal / polymerization Microsphere Janus particles. Characterize the structure of the resulting Janus particles with a transmission electron microscope (TEM), as image 3 shown. Compared with Example 1, the size of the noble metal Janus particles prepared in this example is obviously...

Embodiment 3

[0033] (1) Preparation of core-shell polymer microspheres

[0034] With embodiment 1.

[0035] (2) Preparation of noble metal / polymer microsphere Janus particles

[0036]Take 1mL of the polymer microsphere emulsion in step (1) and dilute it to 10mL with deionized water; add 0.3mL of chloroauric acid aqueous solution with a concentration of 10mmol / L drop by drop under stirring; add 0.3mL of a concentration of 20mmol / L after 1 hour Sodium borohydride aqueous solution, stirring at room temperature for 3 hours; adding 0.0094g cetyltrimethylammonium bromide and 1.0mL concentration of 10mmol / L chloroauric acid aqueous solution, stirring for one hour and then standing for 4 hours to obtain precious metal / polymerization Microsphere Janus particles. Characterize the structure of the resulting Janus particles with a transmission electron microscope (TEM), as image 3 shown. Comparing Example 2, it can be seen that the structure of the Janus particles prepared in this example does no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com