Biomass methanol diesel oil and preparation method thereof

A biomass and methanol technology, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of corrosive biodiesel technology, such as cumbersome technology, poor lubricity equipment, and low cetane number, and achieve environmental protection and safety. Excellent reproducibility, water resistance, and high cetane number effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

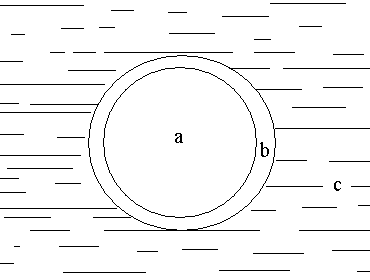

Image

Examples

Embodiment 1

[0021] Composition and ratio of biomass methanol diesel: 100 parts by weight of diesel oil, 40 parts by weight of fatty acid methyl ester, 15 parts by weight of methanol, and 8 parts by weight of composite co-solvent.

[0022] The raw material composition and ratio of the composite co-solvent are as follows: 100 parts by weight of alkylphenol polyoxyethylene ether, 75 parts by weight of sodium dodecylsulfonate, 25 parts by weight of amyl alcohol, and 10 parts by weight of sodium edetate.

[0023] The preparation method of this embodiment is:

[0024] (1) Preparation of composite co-solvent:

[0025] 100 parts by weight of alkylphenol polyoxyethylene ether, 75 parts by weight of sodium dodecyl sulfonate, 25 parts by weight of amyl alcohol, and 10 parts by weight of sodium ethylenediaminetetraacetate are added to the reactor equipped with a stirrer for reaction. In the container, stir evenly to obtain a composite co-solvent system, in which sodium ethylenediaminetetraacetate ac...

Embodiment 2

[0029] Composition and ratio of biomass methanol diesel: 100 parts by weight of diesel oil, 50 parts by weight of fatty acid methyl ester, 20 parts by weight of methanol, and 15 parts by weight of composite co-solvent.

[0030] Wherein the raw material composition and proportioning of the composite co-solvent: Tween80: 100 parts by weight, sodium dodecylbenzenesulfonate: 60 parts by weight, isobutanol: 20 parts by weight, sodium tartrate: 15 parts by weight.

[0031] The preparation method of this embodiment is:

[0032] (1) Preparation of composite co-solvent:

[0033] The Tween80 of 100 parts by weight, the sodium dodecylbenzenesulfonate of 60 parts by weight, the isobutanol of 20 parts by weight, the sodium tartrate of 15 parts by weight are successively added in the reactor that agitator is equipped with, stir evenly, obtain A compound co-solvent system, in which sodium tartrate acts as a stabilizer to complex heavy metal ions.

[0034] (2) Preparation of biomass...

Embodiment 3

[0037] Composition and ratio of biomass methanol diesel: 100 parts by weight of diesel oil, 50 parts by weight of fatty acid methyl ester, 30 parts by weight of methanol, and 20 parts by weight of composite co-solvent.

[0038] The raw material composition and ratio of the composite auxiliary solvent are as follows: Span80: 100 parts by weight, sodium dodecylbenzenesulfonate: 70 parts by weight, isoamyl alcohol: 25 parts by weight, and sodium citrate: 20 parts by weight.

[0039] The preparation method of this embodiment is:

[0040] (1) Preparation of composite co-solvent:

[0041] The Span80 of 100 parts by weight, the sodium dodecylbenzenesulfonate of 70 parts by weight, the isoamyl alcohol of 25 parts by weight, the sodium citrate of 20 parts by weight are successively added in the reactor that agitator is equipped with, stir evenly, A complex co-solvent system is obtained, in which sodium tartrate is used as a stabilizer to complex heavy metal ions.

[0042] (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com