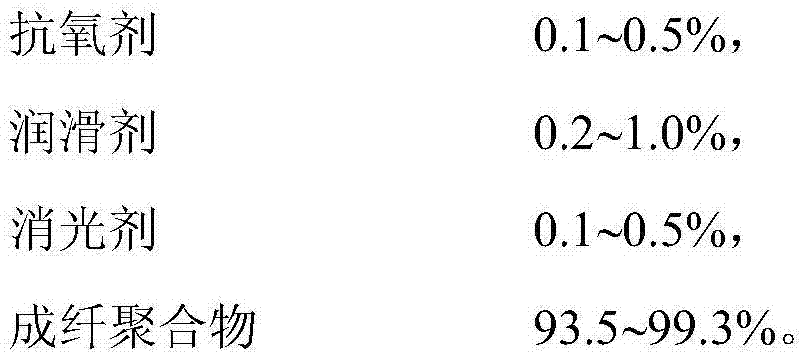

Tingible spandex fiber and preparation method thereof

A technology of spandex fiber and fiber-forming polymer, which is applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problems of narrowing the range of dye selection, failing to achieve printing and dyeing effects, and general printing and dyeing effects, and achieve industrialization. Easy to implement, improve dyeability and color fastness, and facilitate promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Preparation of Surface Treatment Silica

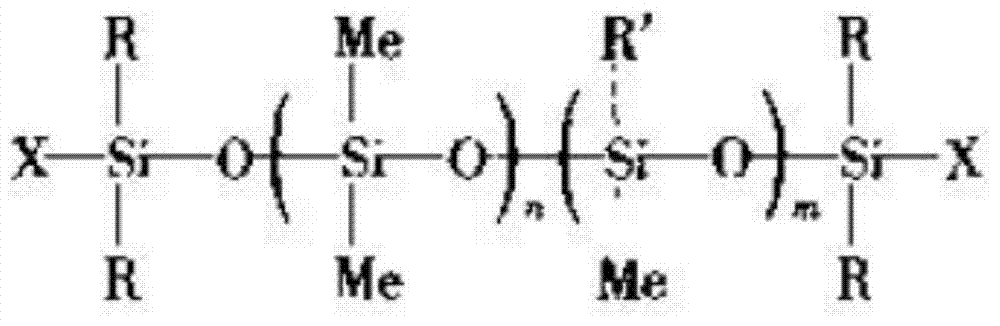

[0028] 1) Modified silicone oil has the following molecular formula, R' is -CH2CH2NHCH2CH3, R is CH 3 ; Molecular weight 5000g / mol.

[0029]

[0030] 2) Dry the white carbon black, evacuate to 0.0001 standard atmospheric pressure, and dry at 120°C for 6 hours;

[0031] 3) Charge treatment: Spray the dried silica with an electronic spray gun to charge the silica, add the charged silica to the modified silicone oil, and stir vigorously, wherein the mass ratio of the modified silicone oil to the silica is 50:1;

[0032] 4) Drying the above solution of white carbon black and modified silicone oil at 320° C. to obtain surface-treated white carbon black.

[0033] Step 2: Preparation of fiber-forming polymer

[0034] 1) Mix the raw materials polytetramethylene ether glycol and 4,4-diphenylmethane diisocyanate, and react at 90°C for 120 minutes to prepare a prepolymer, in which 4,4-diphenylmethane diisocyanate and polytet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com