Cellulose absorbent with controllable structure and preparation method thereof

A cellulose and adsorbent technology, applied in the field of functional polymer materials, can solve problems such as narrow molecular weight distribution, and achieve the effects of large adsorption capacity, good adsorption performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

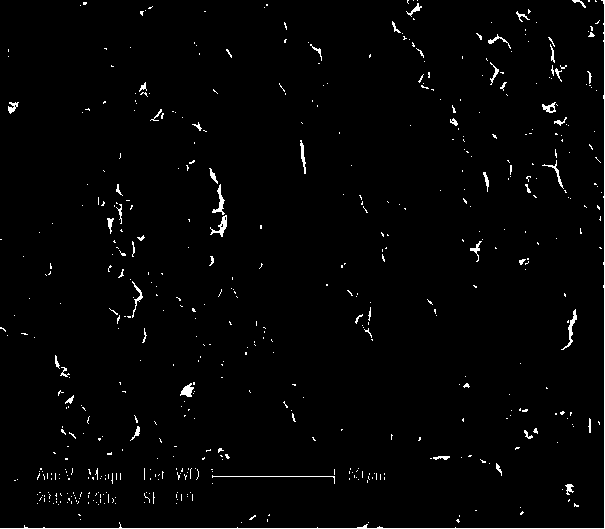

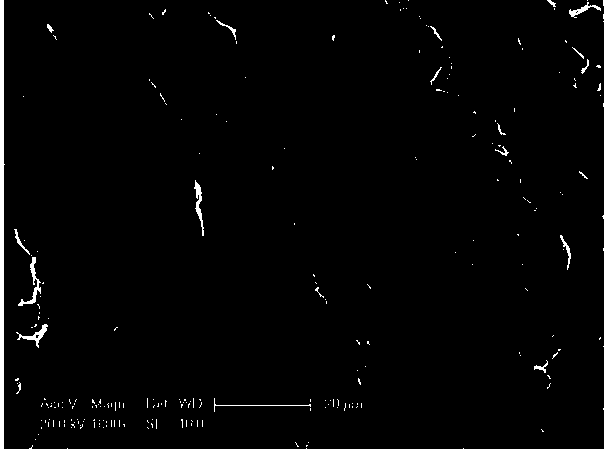

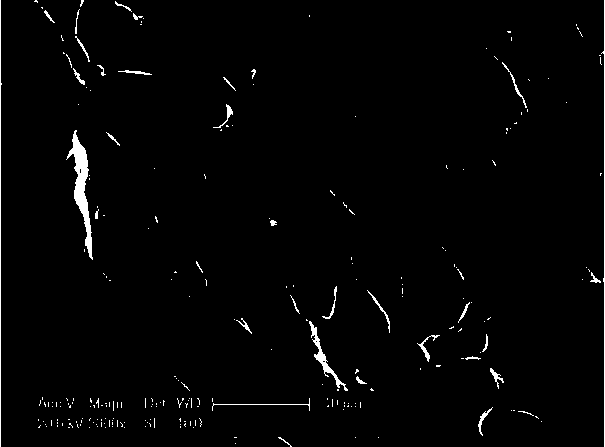

Image

Examples

Embodiment 1

[0035] Embodiment 1: the specific steps of this embodiment are as follows:

[0036] (1) Homogeneous graft copolymerization of cellulose in ionic liquid:

[0037] The raw material components used in this embodiment are as follows:

[0038] Absorbent cotton: 0.51 kg

[0039] Ionic liquid ([Emim]Cl): 65.79 kg

[0040] Chloroacetyl chloride: 3.33 kg

[0041] Cuprous bromide: 1.67 kg

[0042] 2-2 bipyridine: 1.19 kg

[0043] Ascorbic acid: 0.20 kg

[0044] Glycidyl methacrylate monomer: 27.31 kg

[0045] Process steps and parameters of living radical polymerization of cellulose in ionic liquid: put 0.51 kg of absorbent cotton and 65.79 kg of ionic liquid ([Emim]Cl) into the reactor, dissolve at 90°C for 5 hours, and form a mass fraction of 0.77% cellulose-ionic liquid solution; the above solution was cooled to 50°C, 3.33 kg of chloroacetyl chloride was added, reacted for 5 hours, and then nitrogen gas was passed, and 1.80 kg of cuprous bromide, 1.26 kg of 2-2 bipyridine, 0.0...

Embodiment 2

[0053] Embodiment 2: the specific steps of this embodiment are as follows:

[0054] (1) Homogeneous graft copolymerization of cellulose in ionic liquid:

[0055] The raw material components used in this embodiment are as follows:

[0056] Cotton fiber: 0.23 kg

[0057] Ionic liquid ([Bmim]Cl): 80.73 kg

[0058] Bromoacetyl bromide: 2.18 kg

[0059] Cuprous chloride: 3.46 kg

[0060] N,N,N',N'',N''-pentamethyldiethylenetriamine: 1.74 kg

[0061] Stannous octoate: 1.30 kg

[0062] Glycidyl methacrylate monomer: 10.36 kg

[0063] The process steps and parameters of living radical polymerization of cellulose in ionic liquid: 0.23 kg of cotton fiber and 82.03 kg of ionic liquid ([Bmim]Cl) were put into the reactor, dissolved at 100°C for 4 hours, and the mass fraction was 0.28 % of cellulose-ionic liquid solution; cool the above solution to 20°C, add 2.18 kg of bromoacetyl bromide, react for 4 hours, and then pass nitrogen, add 3.46 kg of cuprous chloride, 1.74 kg of N,N,N',...

Embodiment 3

[0071] Embodiment 3: the specific steps of this embodiment are as follows:

[0072] (1) Homogeneous graft copolymerization of cellulose in ionic liquid:

[0073] The raw material components used in this embodiment are as follows:

[0074] Absorbent cotton: 0.61 kg

[0075] Ionic liquid ([Amim]Cl): 41.83 kg

[0076] Chloroacetyl chloride: 5.27 kg

[0077] Nail bromide: 0.78 kg

[0078] 2-Pyridineformaldehyde n-propylamine: 0.39 kg

[0079] Vitamin C: 0.96 kg

[0080] Glycidyl methacrylate monomer: 50.16 kg

[0081] Process steps and parameters of living radical polymerization of cellulose in ionic liquid: put 0.61 kg of absorbent cotton and 41.83 kg of ionic liquid ([Amim]Cl) into the reactor, dissolve at 90°C for 5 hours, and form a mass fraction of 1.44% cellulose-ionic liquid solution; the above solution was cooled to 50°C, 5.27 kg of chloroacetyl chloride was added, reacted for 1 hour, and then nitrogen gas was passed, and 0.78 kg of nail bromide, 0.78 kg of 2-pyridi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com