Purification method for lactoferrin and lactoperoxidase

A lactoperoxidase and purification method technology, which is applied in the field of lactoferrin and lactoperoxidase purification, can solve the problems of cumbersome methods, small processing capacity, and difficulty in large-scale production, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 contains the pretreatment of recombinant human lactoferrin milk sample

[0029] Collection of milk samples from mammals containing recombinant human lactoferrin (0.1-5 g / L), including milk samples from transgenic animals containing recombinant human lactoferrin, or non-transgenic milk mixed with recombinant human lactoferrin Animal milk samples, where milk samples are preferably fresh liquid milk samples, or liquid milk samples obtained after thawing frozen samples or reconstituted milk powder. Mammalian milk samples include cow milk, goat milk, rabbit milk, etc., with milk as the preferred. First, the milk containing recombinant human lactoferrin is skimmed through a butterfly centrifuge to obtain skim milk with a fat content of less than 0.2%, and then 1.4 μm ceramic membrane technology is used to remove bacteria in the milk. The operating temperature is 0-35 ° C. The inlet pressure is 0.3MPa~0.5MPa, then open the permeation valve, set the operating pres...

Embodiment 2

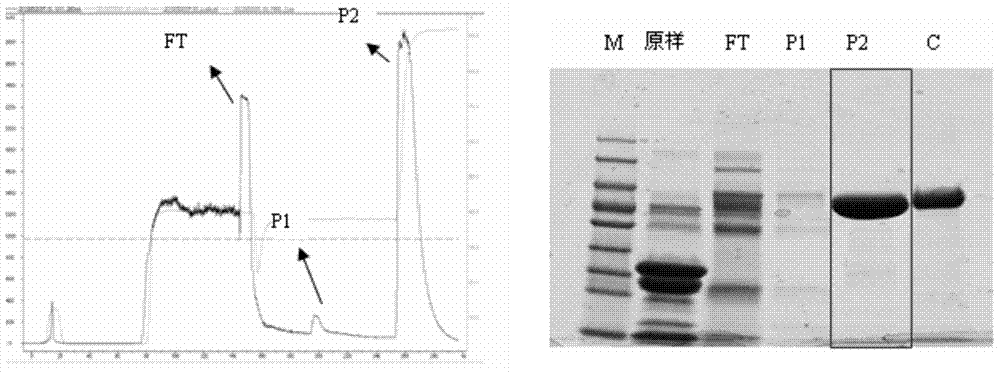

[0030] Embodiment 2 SP Sepharose Big Beads cation exchange chromatography separation

[0031] The skim milk prepared in Example 1 was loaded onto the SP Sepharose Big Beads cation exchange chromatography column equilibrated with 5mM EDTA, 3ms / cm, pH6.5 phosphate buffer, and the flow rate was 150cm / h. After loading, use Wash the chromatography column with 5mM EDTA, 3ms / cm, pH6.5 phosphate buffer to the baseline, use 1%Triton X-114, 13ms / cm NaCl, 3ms / cm phosphate buffer (pH6.5) to The protein solution of lactoperoxidase was eluted and analyzed for purity by gel filtration chromatography, and the protein purity was ≥80%. Since lactoferrin can bind tightly with endotoxin, the antibacterial ability of lactoferrin is limited, and the use of non-ionic detergent can encapsulate endotoxin in the capsule and metal complexing agent can form a gap between endotoxin and protein. The calcium bridge of the recombinant human lactoferrin is broken, so the present invention adopts the method o...

Embodiment 3

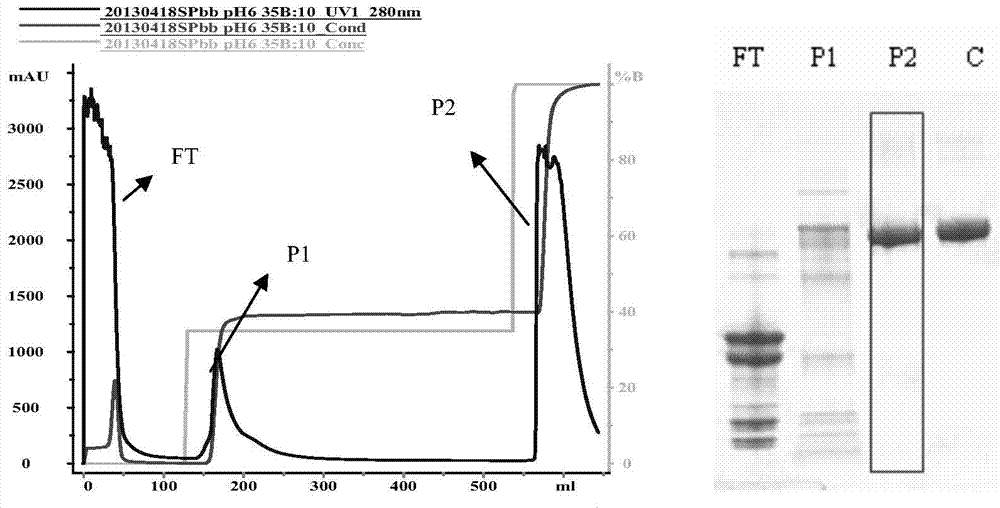

[0032] Embodiment 3SP Sepharose Fast flow cation exchange chromatography separation

[0033] Pack the commercially available SP Sepharose Fast flow filler into the XK26 / 40 chromatographic column. The skim milk prepared in Example 1 was loaded onto the SP Sepharose Fast flow cation-exchange chromatography column equilibrated with 4ms / cm pH6.0 phosphate buffer, the flow rate was 74cm / h, and after the loading was completed, use 4ms / cm cm, pH 6.0 phosphate buffer solution to wash the chromatography column until the 280nm absorption signal reaches the baseline, then use 11ms / cm NaCl, 4ms / cm phosphate buffer solution (pH 6.0) to wash the protein solution containing lactoperoxidase Take it off, and then use 84ms / cm NaCl, 4ms / cm phosphate buffer (pH6.0) to single-elute lactoferrin, and perform purity analysis by gel filtration chromatography. The protein purity is ≥95%. At this time, the protein is pure The product solution contains 5% bovine endogenous lactoferrin. figure 2 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com