A kind of recycling method of waste diatomite filter cake in plasticizer factory

A technology for waste diatomite and soil filter cake is applied in the field of reuse of waste diatomite filter cake in plasticizer factories, which can solve the problems of high treatment cost, secondary pollution, waste gas environmental pollution and the like, and achieves a simple production process. , Conducive to environmental protection, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

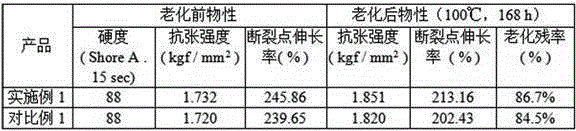

Embodiment 1

[0034] 1) Weigh raw materials:

[0035] 100 parts by weight of polyvinyl chloride resin (PVC),

[0036] 120 parts by weight of spent diatomite filter cake,

[0037] Composite heat stabilizer 3 parts by weight.

[0038] The composite heat stabilizer is a mixture of calcium isooctanoate, zinc isooctanoate, calcium benzoate, and phosphite antioxidant 3010 (Zhiyi Seika) in a mass ratio of 3:3:2:1.

[0039] Among them, the waste diatomite filter cake is screened, and impurities (such as screws, iron slag, etc.) are removed by rolling sieves, vibrating sieves, and translational sieves, dried and ground to 60 mesh.

[0040] 2) Transport the raw materials to a high-speed mixer for kneading according to the proportioning ratio to obtain a mixture. The kneading temperature is 130° C. and the kneading time is 10 minutes.

[0041] 3) The mixture is fed by a screw feeder and conveyed to a conical twin-screw extruder for extrusion. The temperature of the body of the extruder is 170°C, an...

Embodiment 2

[0045] 1) Weigh raw materials:

[0046] PVC100 parts by weight,

[0047] 100 parts by weight of waste diatomite filter cake,

[0048] Plasticizer DOTP20 parts by weight,

[0049] Composite heat stabilizer 3 parts by weight.

[0050] The composite heat stabilizer is a mixture of calcium isooctanoate, zinc isooctanoate, calcium benzoate, barium benzoate, and phosphite (WESTON) in a mass ratio of 5:5:4:1:1.

[0051] Among them, the waste diatomite filter cake is screened, dried and ground to 100 mesh.

[0052] 2) Transport the raw materials to a high-speed mixer according to the proportion and knead them to obtain a mixture. The kneading temperature is 100° C. and the kneading time is 30 minutes.

[0053] 3) The mixture is fed by a screw feeder and conveyed to a conical twin-screw extruder for extrusion. The temperature of the body of the extruder is 150°C, and the temperature of the head of the extruder is 155°C.

[0054] 4) Extrude the strip-shaped plastic, and cut it into...

Embodiment 3

[0057] 1) Weigh raw materials:

[0058] PVC100 parts by weight,

[0059] 200 parts by weight of spent diatomite filter cake,

[0060] 0.2 parts by weight of paraffin,

[0061] 0.3 parts by weight of calcium stearate,

[0062] Composite heat stabilizer 5 parts by weight.

[0063] The composite heat stabilizer is a mixture of barium isooctanoate, zinc benzoate, and phosphite (WESTON) in a mass ratio of 6:5:1.

[0064] Among them, the waste diatomite filter cake is screened, dried and ground to 100 mesh.

[0065] 2) Transport the raw materials to a high-speed mixer for kneading according to the proportioning ratio to obtain a mixture. The kneading temperature is 130° C. and the kneading time is 10 minutes.

[0066] 3) The mixture is fed by a screw feeder and conveyed to a conical twin-screw extruder for extrusion. The temperature of the body of the extruder is 170°C, and the temperature of the head of the extruder is 180°C.

[0067]4) Extrude the strip-shaped plastic, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com