Preparation method of palladium membrane

The technology of a palladium membrane and a palladium alloy membrane, which is applied in the field of hydrogen separation, can solve the problems of reducing the hydrogen permeability and service life of the membrane, affecting the service life of the palladium membrane, etc., and achieves the effects of superior performance, easy operation and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

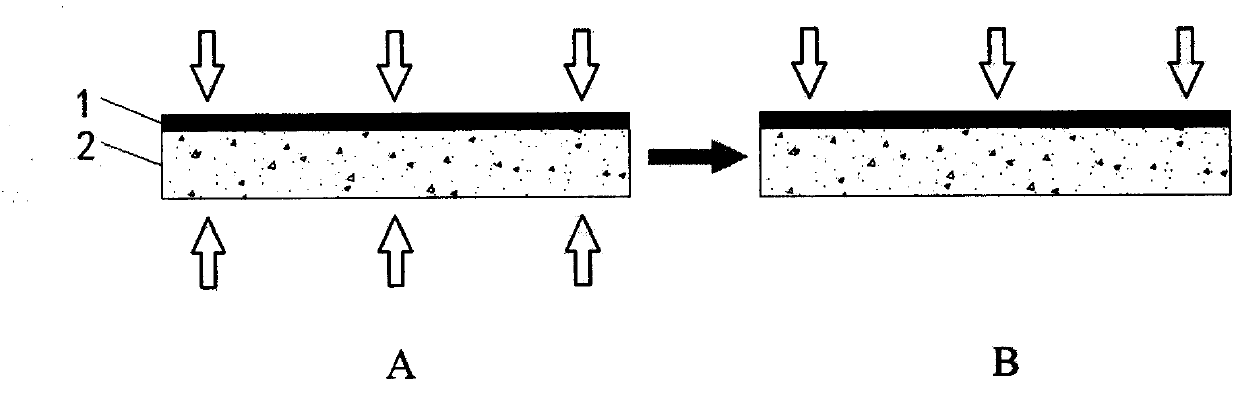

[0022] Adopting the present invention to prepare a palladium membrane on the outer surface of a tubular porous ceramic substrate comprises the following steps:

[0023] (1) The substrate used is a tubular porous ceramic with an outer diameter of 13 mm, an inner diameter of 8 mm, a length of 80 mm, and a maximum pore diameter of 2.6 μm on the surface. The substrate is cleaned and dried for later use.

[0024] (2) Using SnCl 2 / PdCl 2 The activation method is used to activate the outer surface of the above-mentioned substrate, and the sensitization solution contains SnCl 2 4g / L, hydrochloric acid 1ml / L, the activation solution contains PdCl 2 0.2g / L, hydrochloric acid 1ml / L, after sensitization and activation treatment 4 times.

[0025] (3) Immerse the activated substrate into the plating solution to start electroless plating. The composition of the plating solution: PdCl 2 5g / L, Na 2 EDTA50g / L, ammonia water 250ml / L, bath temperature 30°C. The reducing agent is 0.4mol / L ...

Embodiment 2

[0030] Adopting the present invention to prepare a palladium membrane on the outer surface of a tubular porous stainless steel substrate comprises the following steps:

[0031] (1) The substrate used is tubular porous stainless steel with an outer diameter of 12 mm, an inner diameter of 7 mm, a length of 80 mm, and a maximum pore diameter of 6.5 μm on the surface. The substrate is cleaned and dried for later use.

[0032] (2) with the step (2) (3) (4) (5) of embodiment 1, but stop electroless plating when palladium film thickness reaches 10 μ m, calculate according to the weight gain of substrate, palladium film thickness is 9.7 μ m, records Its nitrogen flux is 3.8ml / min. The flux after pressure sintering is reduced to 1.35ml / min.

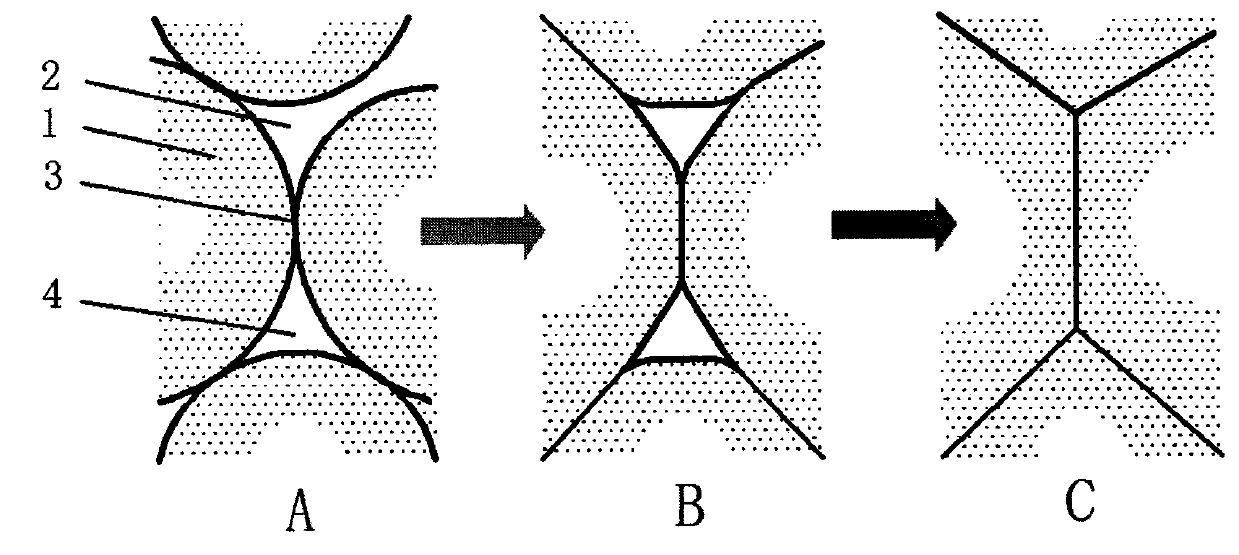

[0033] (3) Carry out chemical repair on the above-mentioned palladium film, and the repair liquid is selected from 0.001mol / L Pd(OH) 2 The colloid and the membrane tube are immersed in the repair solution to make the Pd(OH) 2 The colloid penet...

Embodiment 3

[0035] Adopt the present invention to prepare palladium film on sheet type porous ceramic substrate, comprise the following steps:

[0036] (1) The substrate used is a circular sheet-type porous ceramic with a diameter of 30 mm, a thickness of 2 mm, and a maximum diameter of surface pores of 2.5 μm. The substrate is cleaned and dried for later use.

[0037] (2) Steps (2) (3) (4) (5) (6) with embodiment 1. However, based on the weight gain of the substrate, the thickness of the palladium film is 4.9 μm, and the measured nitrogen flux is reduced from 0.51ml / min to 0.22ml / min after pressure sintering. After the hydrazine repair method, the nitrogen flux was 0.10ml / min, and the nitrogen flux was 0.18ml / min after the palladium membrane was used for 900h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com