Microbial fermentation functional organic compound fertilizer and production method thereof

A microbial fermentation and production method technology, which is applied in the field of microbial fermentation functional organic compound fertilizer and its production, can solve the problems of poor survival of effective microorganisms and short shelf life, etc., to improve germination rate and crop stress resistance, improve shelf life, The effect of improving disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Cultivation of primary strains

[0039] The percentage by weight of each component of the primary strain culture medium is:

[0040] Industrial whey powder 2%, industrial sodium lactate 0.4%, industrial anhydrous sodium acetate 0.1%, industrial peptone 1%, soybean meal powder 3%, industrial glucose 1.5%, yeast extract powder 0.5%, tap water 91.5%, pH natural, above Mix and stir to dissolve.

[0041] Specific operation: first take a 500ml triangular flask, fill each bottle with 200ml of the above-dissolved culture medium, then seal the triangular flask with 6-8 layers of gauze, wrap it with a layer of kraft paper, and put it into a medical pressure sterilizer for steam sterilization; first Turn on the heating source of the sterilizer, and when the steam pressure in the sterilizer reaches 0.05 MPa, open the exhaust valve on the sterilizer to discharge cold air for 6-8 minutes; when the pressure gauge on the sterilizer returns to normal At zero hour, close the exhaust va...

Embodiment 2

[0051] Utilize the method for above-mentioned seed tank cultivating bacterial classification to ferment biological organic fertilizer, concrete steps are as follows:

[0052] The formula is as follows: Take 100kg fertilizer as an example, excluding water and bacteria

[0053] Dry chicken manure 30kg, dry pig manure 53.4kg, 40 mesh fine rice husk powder 10kg, lactose 0.1kg, chitosan oligosaccharide 0.5kg, wheat bran 6kg, weigh and mix all materials, add 40kg of tap water and mix well, pile up and park for 5 hour, then add 2wt% of the above-cultured seed tank bacterial classification (2wt% of the dry material), first add after adding by diluting with tap water in a ratio of 1:3, both 1kg of bacteria liquid and 3kg of tap water, turn over while adding , add the bacteria and mix well and start stacking. It needs to be stacked into a long stack with a bottom width of 1.5 meters, an upper width of 1.2 meters, a height of 1.2 meters, and an unlimited length. The cross-section of the...

experiment example 4

[0075] After the inventor added lactose and chitosan, the impact on the final result was compared, and the results are as follows:

[0076] Comparison table 4 of trehalose produced by active dry yeast with added lactose

[0077]

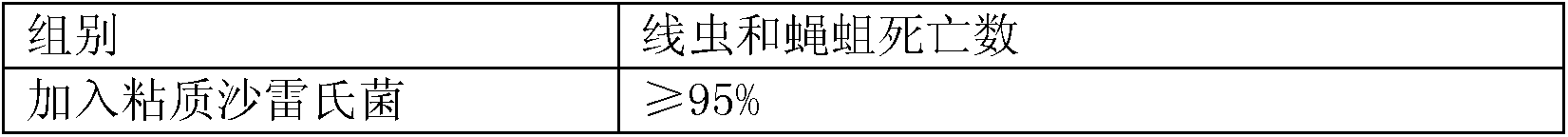

[0078] Adding chitosan oligosaccharide in production improves the effect of Lactobacillus brevis on degrading hormones, and also improves the effect of Bacillus cereus on degrading drug residues.

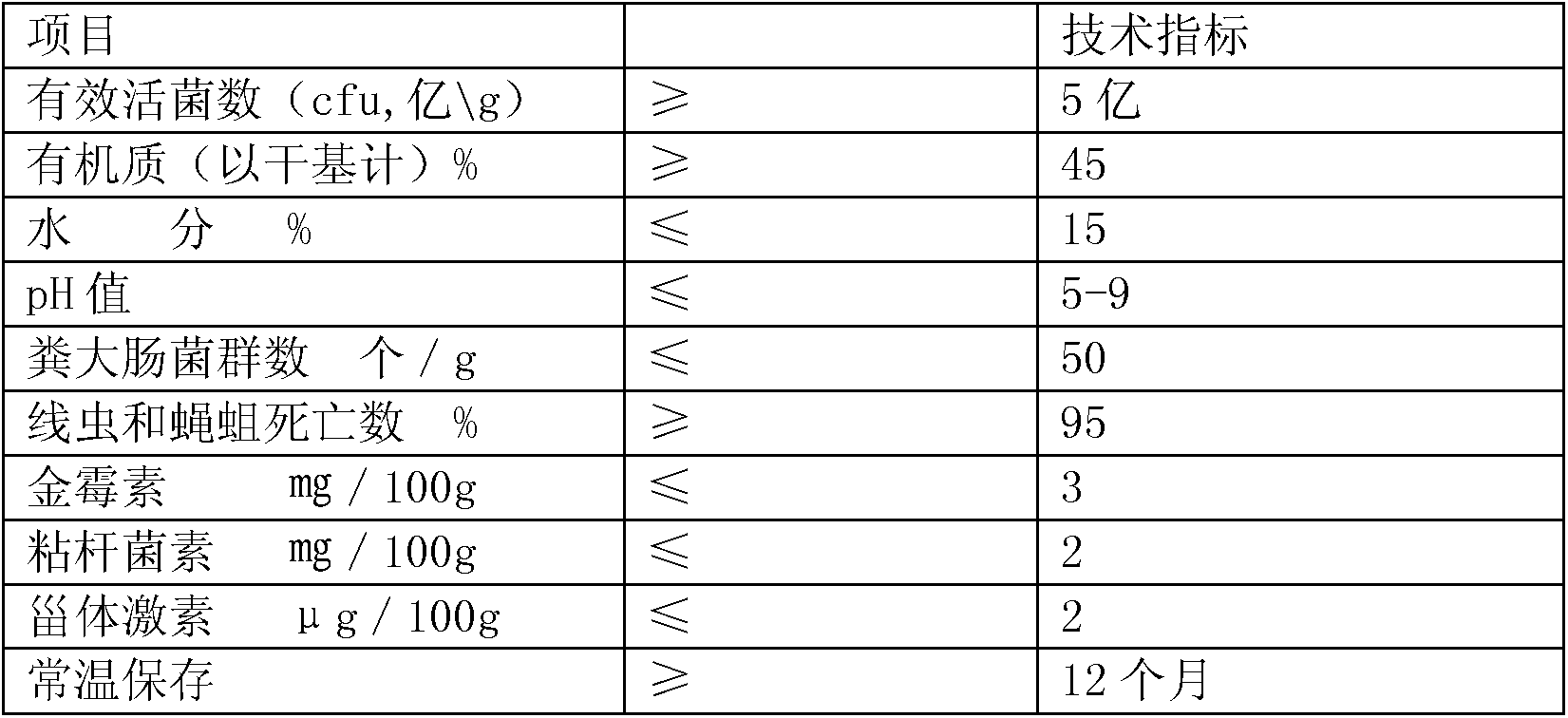

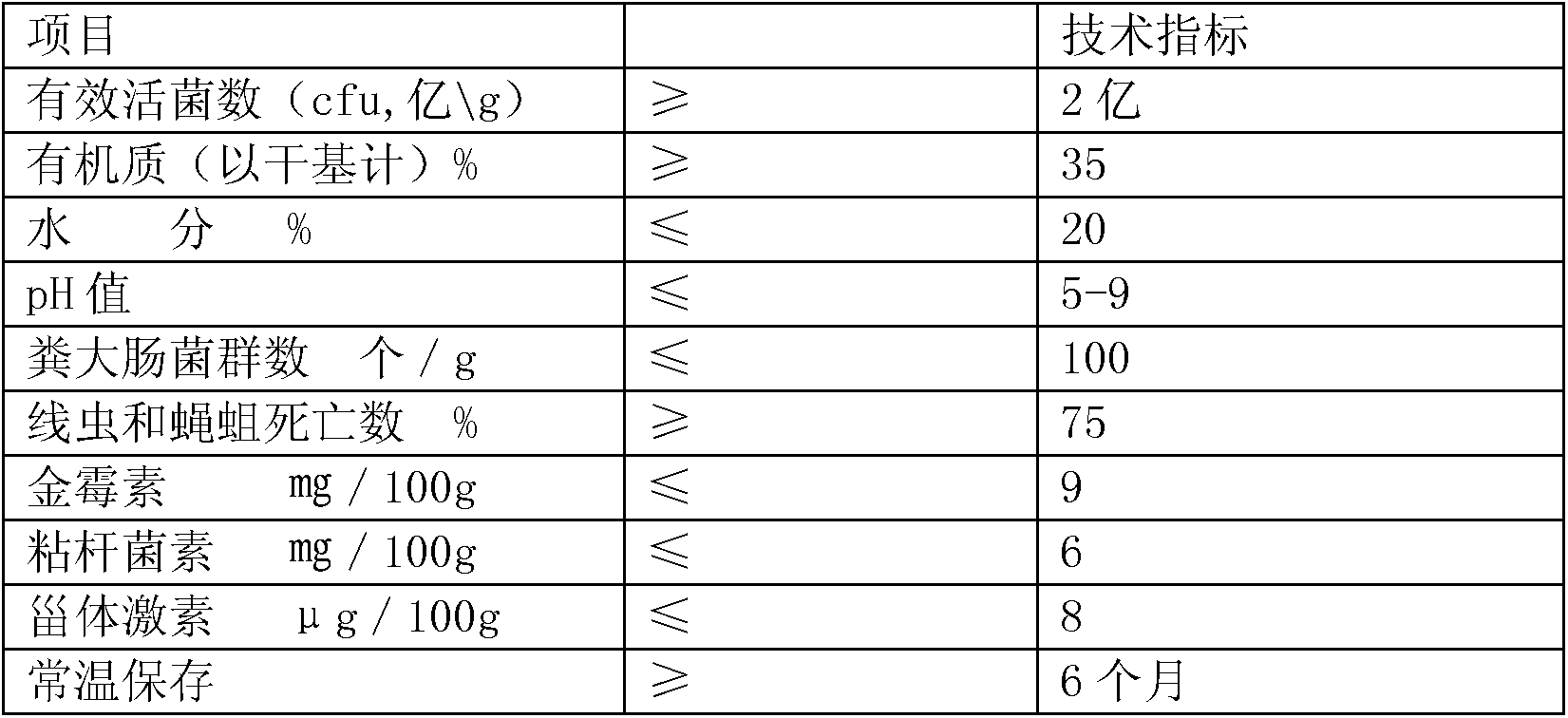

[0079] Determination effect of estrogen in organic fertilizer degraded by Lactobacillus brevis Table 5

[0080]

[0081]

[0082] Add the assay result table 6 of the bacterial classification fermentation organic fertilizer hormone of chitosan oligosaccharide

[0083]

[0084] Test results of Bacillus cereus degrading drug residues in organic fertilizer Table 7

[0085]

[0086] Table 8

[0087]

[0088] It can be seen that adding lactose and chitooligosaccharides to the cultured strains can make the strains produce the required effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com