Special growing pig enzyme containing alkaline xylanase and preparation method thereof

A technology of acid xylanase and xylanase, which is applied in the field of enzyme preparation, can solve problems such as unmeasured and complex structures, and achieve the effects of high activity, high temperature tolerance and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

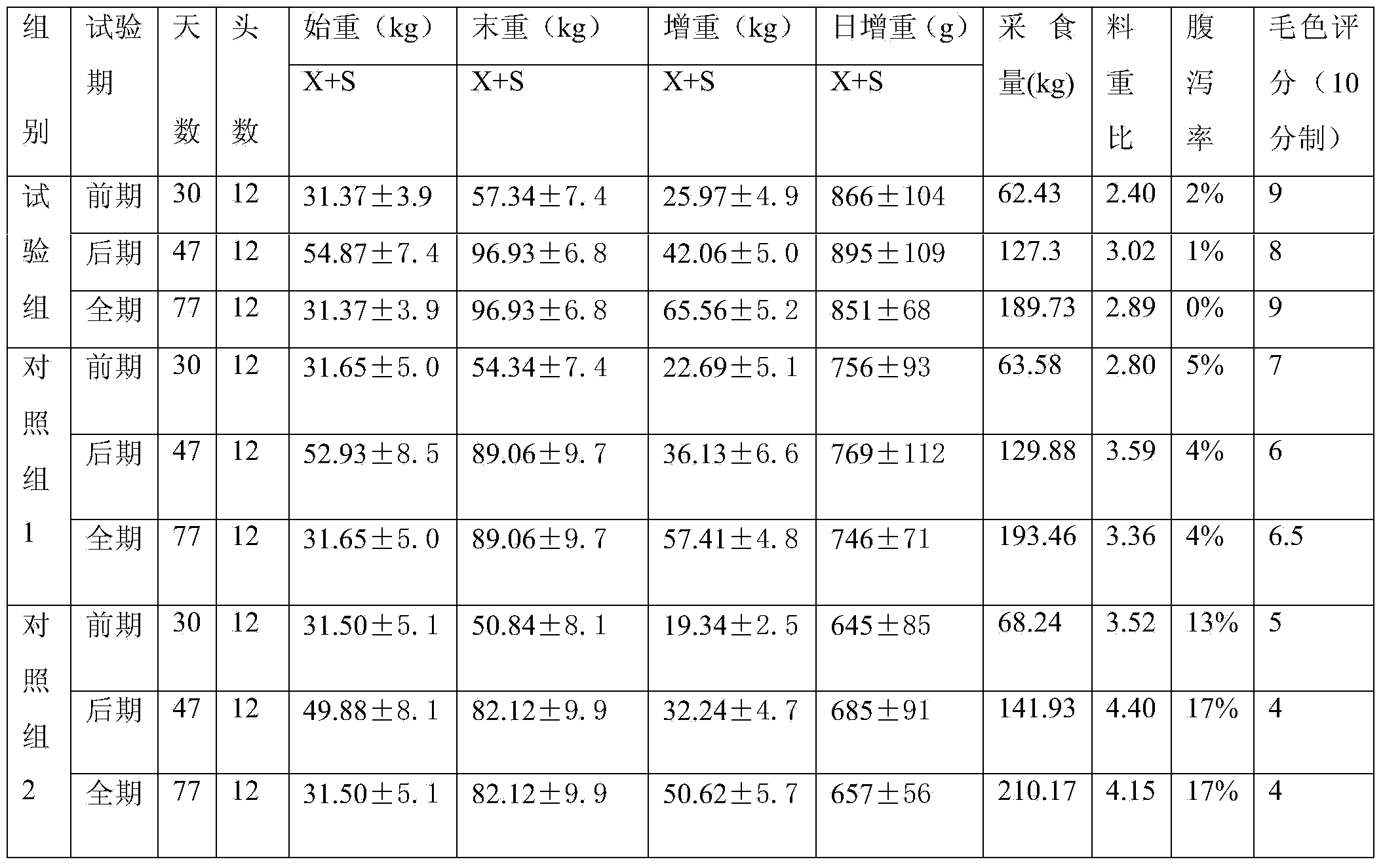

Examples

Embodiment 1

[0054] A special enzyme for growing pigs containing alkaline xylanase, which consists of the following raw materials in parts by weight:

[0055] Thermophilic Bacillus culture 40 parts, acid protease 45 parts, acid xylanase 25 parts, beta-glucanase 25 parts, pectinase 25 parts, cellulase 12 parts, amylase 12 parts, phytic acid 12 parts of enzyme, 12 parts of Chinese herbal medicine extract, 12 parts of protective agent, 12 parts of activator.

[0056] Described acid protease, acid xylanase, beta-glucanase, pectinase, cellulase, amylase, phytase are all food-grade enzyme preparations;

[0057] The preparation method of described thermophilic bacillus culture comprises the steps:

[0058] (1) Activation of strains

[0059] Inoculate the slant strain of the well-preserved thermophilic Bacillus 701 on the slant medium, culture at 37°C for 24 hours to activate the strain, and activate twice in this way;

[0060] The slant medium consists of: 3g of beef extract, 5g of sodium chlo...

Embodiment 2

[0096] A special enzyme for growing pigs containing alkaline xylanase, which consists of the following raw materials in parts by weight:

[0097] Thermophilic Bacillus culture 30 parts, acid protease 35 parts, acid xylanase 20 parts, β-glucanase 20 parts, pectinase 20 parts, cellulase 10 parts, amylase 10 parts, phytic acid 10 parts of enzyme, 10 parts of Chinese herbal medicine extract, 10 parts of protective agent, 10 parts of activator.

[0098] Described acid protease, acid xylanase, beta-glucanase, pectinase, cellulase, amylase, phytase are all food-grade enzyme preparations;

[0099] The preparation method of described thermophilic bacillus culture comprises the steps:

[0100] (1) Activation of strains

[0101] Inoculate the slant strain of the well-preserved thermophilic Bacillus 701 on the slant medium, culture at 41°C for 30 hours to activate the strain, and activate it 3 times;

[0102] The slant medium consists of: 6g of beef extract, 8g of sodium chloride, 15g of...

Embodiment 3

[0137] A special enzyme for growing pigs containing alkaline xylanase, which consists of the following raw materials in parts by weight:

[0138] 50 parts of thermophilic bacillus culture, 55 parts of acid protease, 30 parts of acid xylanase, 30 parts of beta-glucanase, 30 parts of pectinase, 15 parts of cellulase, 15 parts of amylase, phytic acid 15 parts of enzyme, 15 parts of Chinese herbal medicine extract, 15 parts of protective agent, 15 parts of activator.

[0139] Described acid protease, acid xylanase, beta-glucanase, pectinase, cellulase, amylase, phytase are all food-grade enzyme preparations;

[0140] The preparation method of described thermophilic bacillus culture comprises the steps:

[0141] (1) Activation of strains

[0142] Inoculate the slant strain of the well-preserved thermophilic Bacillus 701 on the slant medium, culture at 45°C for 36 hours to activate the strain, and activate it 3 times;

[0143] The slant medium consists of: 10g of beef extract, 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com