Oncomelania-hupensis killing medicament niclosamide-ethanolamine-salt sustained-release granules and preparation method thereof

The technology of spirulina ethanolamine salt and slow-release granules is applied in the field of snail-killing pharmaceutical preparations, which can solve the problems of easy drug injury for users, increased environmental risks and costs, and pollution of the environment, thereby increasing the snail-killing effect and avoiding snail-killing effects. The effect of repeated medication and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

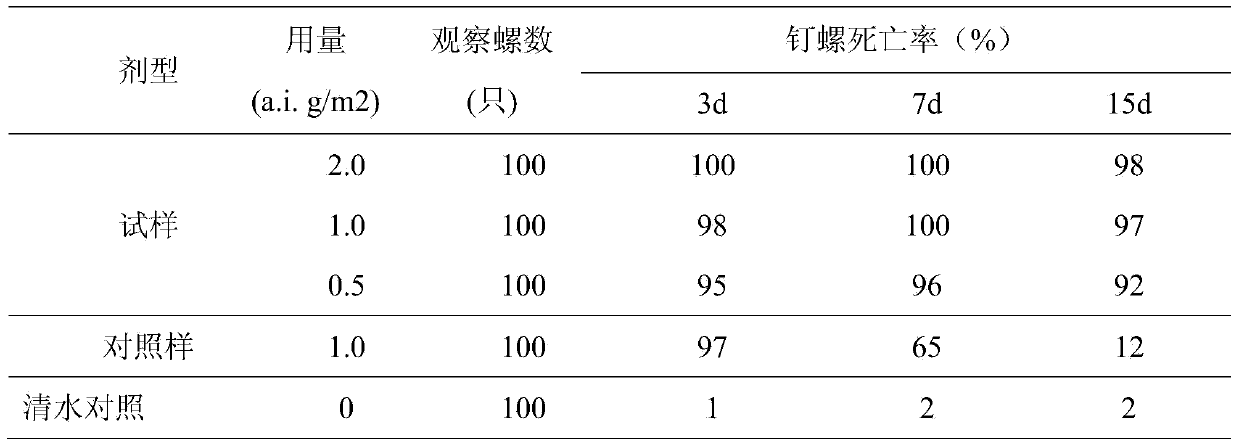

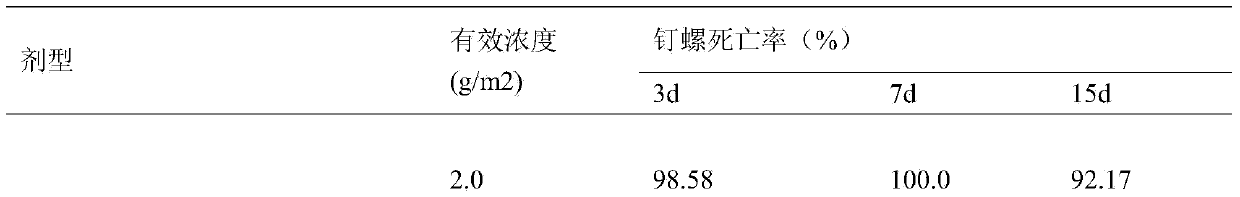

Examples

Embodiment 1

[0013] Example 1: Preparation of spiroxamine ethanolamine salt sustained-release granules

[0014] In terms of mass percentage, 1% spiroxamine ethanolamine salt, 0.1% sodium lauryl sulfate, and 0.5% alkylphenol polyoxyethylene ether formaldehyde polycondensate sulfate are mixed and pulverized by a jet mill to obtain powder; then Add 5% dextrin, 0.2% sodium carboxymethyl cellulose, 2% polyethylene, and starch to 100%, mix evenly, heat, extrude and granulate with high-pressure equipment, spray epoxy resin and furan resin for coating, The coating thickness of the granules is 0.2 mm. Dry to get the product.

Embodiment 2

[0015] Example 2: Preparation of Spiroxamine Ethanolamine Salt Sustained Release Granules

[0016] In terms of mass percentage, 5% spiroxamine ethanolamine salt, 0.2% sodium dodecylbenzene sulfonate, and 1% tea dry are mixed to obtain powder through jet milling; then mixed with 5% hydrogenated vegetable oil, 0.5% polyvinyl alcohol, 10 % cellulose acetate, starch added to 100%, mixed evenly, heated, extruded and granulated by high-pressure equipment, sprayed with epoxy resin and polyacryl acetate for coating, the coating thickness of the granules is 0.3mm. Dry to get the product.

Embodiment 3

[0017] Example 3: Preparation of spiroxamine ethanolamine salt sustained-release granules

[0018] In terms of mass percentage, 5% spiroxamine ethanolamine salt, 0.2% sodium dodecylbenzene sulfonate, and 3% polyvinylpyrrolidone are mixed to obtain powder through jet milling; then mixed with 5% hydrogenated vegetable oil, 0.5% polyvinyl alcohol, 10% cellulose acetate, supplemented with starch to 100%, mixed evenly, heated, extruded and granulated by high-pressure equipment, sprayed with epoxy resin and polyacryl acetate for coating, the coating thickness of the granules is 0.1mm. Dry to get the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com