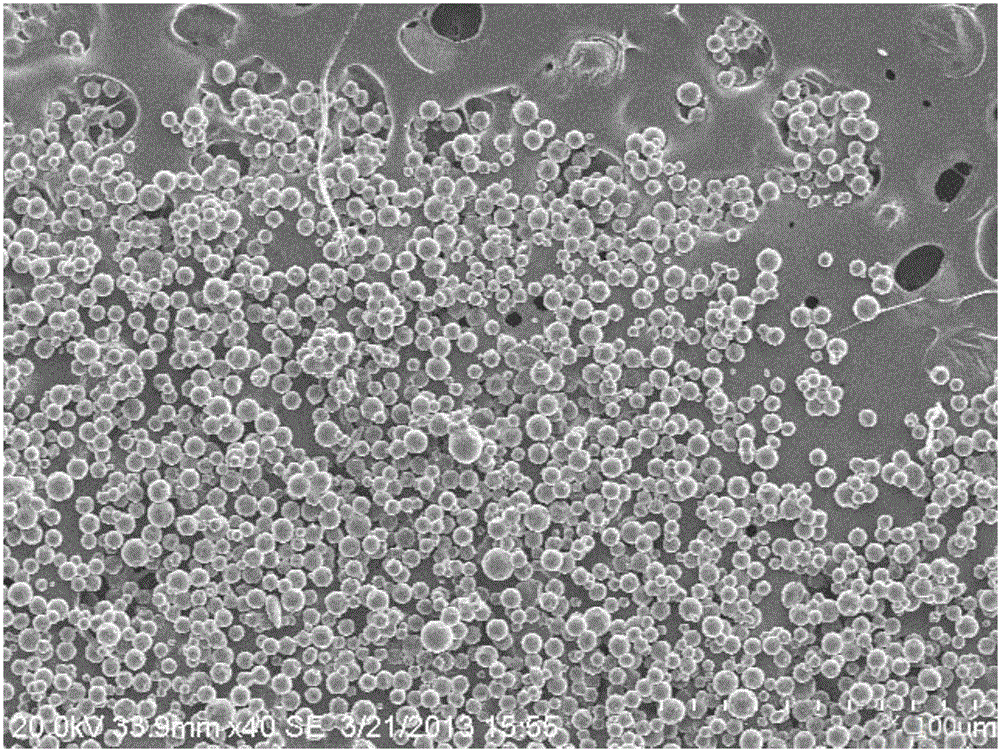

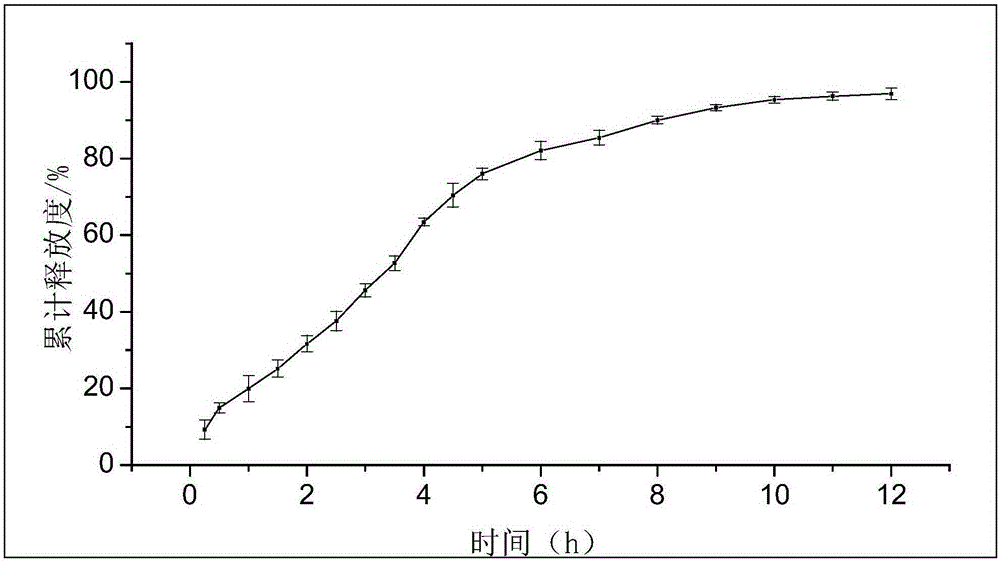

Preparation method of timolol maleate sustained-release microspheres

A technology of timolol maleate and microspheres, applied in the field of medicine, can solve the problems of decreased drug encapsulation rate, long time consumption, low drug loading capacity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of timolol maleate sustained-release microspheres comprises the following steps:

[0027] 5) Disperse timolol maleate, acrylic resin, Tween, plasticizer, and montmorillonite in an organic solvent, so that the concentration of acrylic resin is 30-100g / L, and the concentration of Tween is 20-60g / L L, the concentration of the plasticizer is 5-20g / L to obtain the inner phase;

[0028] 6) Dissolving Span in vegetable oil to make the concentration of Span 10-40g / L to obtain the external phase;

[0029] 7) Under the stirring state, drop the inner phase into the outer phase to form an oil-in-oil emulsion;

[0030] 8) After the emulsion is ultrasonically treated for 5-30 minutes, the inner phase is evaporated under electromagnetic stirring, washed and dried to obtain sustained-release microspheres.

[0031] The emulsifying agent is very important to the stability of the oil-in-oil emulsion, and the emulsifying agent of the present invention is preferably...

Embodiment 1

[0036] 1) Accurately weigh 30 mg of timolol maleate, 20 mg of sodium montmorillonite, 50 mg of TEC, 50 mg of glycerin, 400 mg of acrylic resin (RSPO:RLPO mass ratio = 2:1), 80-124 mg of Tween, and add them into 5 ml of acetonitrile, Stir to disperse and mix to obtain the inner phase.

[0037] 2) Dissolve 248mg of Span 80 in 10ml of vegetable oil to obtain the external phase.

[0038] 3) At a stirring speed of 600 rpm, 0.3 g of the inner phase was added dropwise to 5 g of the outer phase, and dispersed evenly to obtain an oil-in-oil emulsion.

[0039] 4) Put the emulsion in an ultrasonic cell disintegrator and sonicate for 10 minutes, then evaporate the inner phase with electromagnetic stirring in an ice bath, wash with n-hexane, and dry at room temperature.

Embodiment 2

[0041] 1) Place 500 mg of sodium-based montmorillonite in 5v / v% sulfuric acid, activate it at 90°C for 2 hours, wash until neutral, and dry to obtain modified montmorillonite.

[0042] 2) Accurately weigh 30mg of timolol maleate, 20mg of modified montmorillonite, 50mg of TEC, 50mg of glycerin, 400mg of acrylic resin (RSPO:RLPO mass ratio = 2:1), Tween 80124mg, and add it into 5ml of acetonitrile , stir to disperse and mix to obtain the inner phase.

[0043] 3) Dissolve 248mg of Span 80 in 10ml of vegetable oil to obtain the external phase.

[0044] 4) At a stirring speed of 600 rpm, 0.3 g of the inner phase was added dropwise to 5 g of the outer phase, and dispersed evenly to obtain an oil-in-oil emulsion.

[0045] 5) Put the emulsion in an ultrasonic cell disintegrator and sonicate for 10 minutes, then evaporate the inner phase with electromagnetic stirring in an ice bath, wash with n-hexane, and dry at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com