Sulfur-indium-zinc composite material with homogeneous heterogeneous knot, as well as preparation method and application of material

A composite material, indium zinc sulfide technology, applied in catalyst activation/preparation, gallium/indium/thallium compound, hydrogen production and other directions, can solve the problem of low lattice matching, achieve simple and easy control of the process and excellent performance , the effect of large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

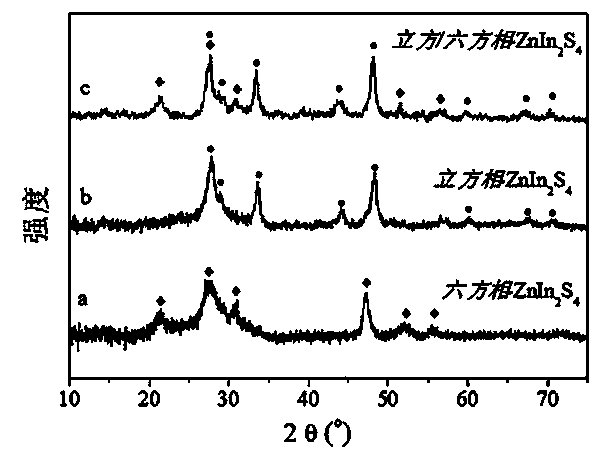

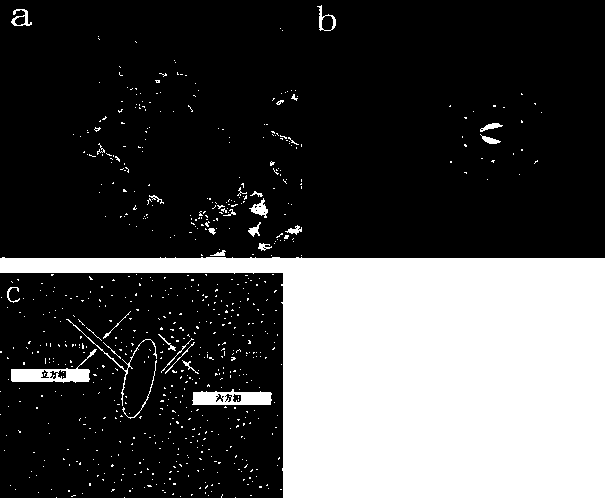

Embodiment 1

[0022] ZnCl 2 (10 mmol), In(NO 3 ) 3 4.5H 2 O (20 mmol), thioacetamide (40 mmol), and polyvinylpyrrolidone (2 g) were added to a polytetrafluoroethylene reactor, and then 70 ml of distilled water / ethanol / tetrachloromethane (volume ratio 1:1:0.2) in the mixture, put the reactor on a magnetic stirrer, adjust the pH value to 2.3, stir for 120 min, put it in an oven at 120 °C for 6 h, and wait for the reactor to cool to room temperature, The mixture in the reaction kettle was taken out, centrifuged, and the obtained precipitate was washed several times with distilled water and ethanol, and then dried in an oven at 60 ° C to obtain an orange powder precursor; the prepared sulfur indium zinc precursor Place it in a tube furnace for calcination under a nitrogen atmosphere, the temperature is controlled at 400°C, and it is kept for 4 hours to obtain a homogeneous and heterogeneous sulfur-indium-zinc composite.

Embodiment 2

[0024] ZnCl 2 (20 mmol), In(NO 3 ) 3 4.5H 2 O (40 mmol), thioacetamide (80 mmol), and polyvinylpyrrolidone (0.2 g) were added to a polytetrafluoroethylene reactor, and then 70 ml of distilled water / ethanol / tetrachloromethane (volume ratio 1:1:0.2) in the mixture, put the reactor on a magnetic stirrer, adjust the pH value to 2.3, stir for 120 min, put it in an oven at 120 °C for 6 h, and wait for the reactor to cool to room temperature, The mixture in the reaction kettle was taken out, centrifuged, and the obtained precipitate was washed several times with distilled water and ethanol, and then dried in an oven at 60 ° C to obtain an orange powder precursor; the prepared sulfur indium zinc precursor Place it in a tube furnace for calcination under a nitrogen atmosphere, the temperature is controlled at 400°C, and it is kept for 4 hours to obtain a homogeneous and heterogeneous sulfur-indium-zinc composite.

Embodiment 3

[0026] ZnCl 2 (10 mmol), In(NO 3 ) 3 4.5H 2 O (20 mmol), thioacetamide (40 mmol), and polyvinylpyrrolidone (1 g) were added to a polytetrafluoroethylene reactor, and then 70 ml of distilled water / ethanol / tetrachloromethane (volume ratio 1:1:0.2) in the mixture, put the reactor on a magnetic stirrer, adjust the pH value to 6, stir for 120 min, put it in an oven at 120 °C for 6 h, and wait for the reactor to cool to room temperature, The mixture in the reaction kettle was taken out, centrifuged, and the obtained precipitate was washed several times with distilled water and ethanol, and then dried in an oven at 60 ° C to obtain an orange powder precursor; the prepared sulfur indium zinc precursor Placed in a tube furnace for calcination under a nitrogen atmosphere, the temperature was controlled at 300 ° C, and kept for 4 h to obtain a homogeneous heterogeneous sulfur indium zinc compound.

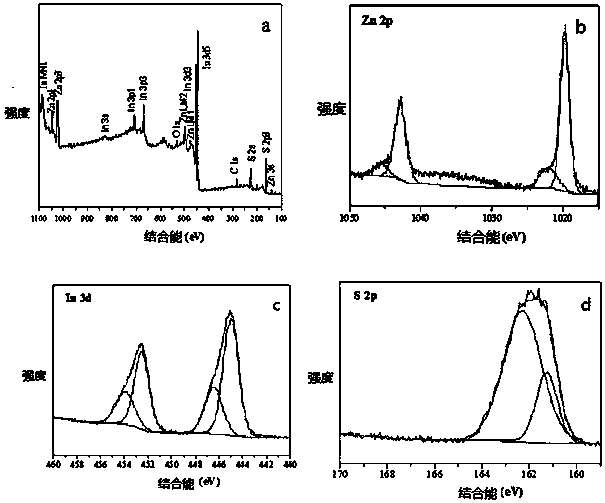

[0027]From figure 1 It can be seen that Zn exists in the form of +2 valence, In exis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com