Preparation method of TiO2(B)@g-C3N4 composite nano-sheet photocatalyst

A photocatalyst, g-c3n4 technology, applied in the field of photocatalytic materials, can solve the problems of low utilization efficiency of photogenerated carriers, difficult to precisely control the composition and structure, uneven distribution of each phase, etc., and achieve good photocatalytic degradation of organic Pollutant and photocurrent response performance, high application prospect and practical value, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

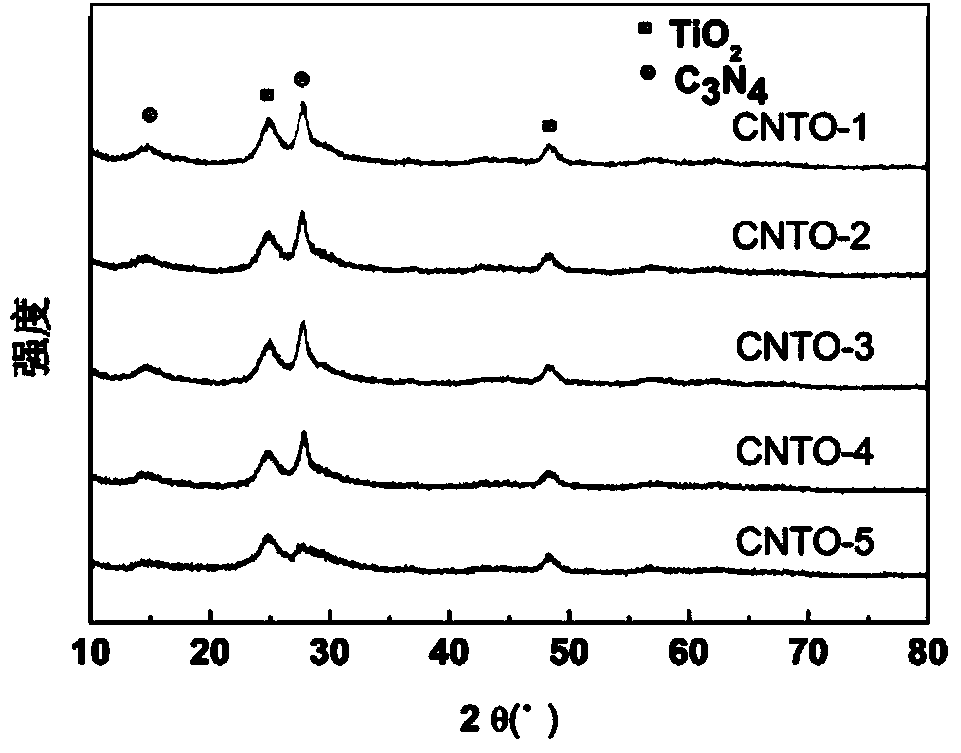

[0024] Take 10g of urea and place it in a crucible, wrap the crucible tightly with aluminum foil, place it in a muffle furnace and calcinate at 550°C in an air atmosphere with a heating rate of 10°C / min, keep it warm for 4 hours and then cool it naturally, the obtained powder is g-C 3 N 4 . Take g-C 3 N 4 Powder 0.1g, with 0.2ml TiCl 4 , 30ml of ethylene glycol, and 1mL of concentrated ammonia water to make a slurry, stir in a water bath at 60°C for 2 hours, transfer it into an autoclave after the heat preservation is completed, and put it in a forced air drying oven for 48 hours at 140°C. After the reaction, the powder was filtered out, rinsed with deionized water and ethanol, and dried to obtain TiO 2 (B)g-C 3 N 4 Composite nanosheet photocatalyst, denoted as CNTO-1. Using methylene blue (MB) as the target degradation product, take TiO 2 (B)g-C 3 N 4 Add 50 mg of composite nanosheet photocatalyst (CNTO-1) into 50 ml of MB solution with a concentration of 10 mg / L. A...

experiment example 2

[0026] Take 10g of urea and place it in a crucible, wrap the crucible tightly with aluminum foil, place it in a muffle furnace and calcinate at 550°C in an air atmosphere with a heating rate of 15°C / min, keep it warm for 4 hours and then cool it naturally, the obtained powder is g-C 3 N 4 . Take g-C 3 N 4 Powder 0.1g, with 0.5ml TiCl 4 , 40ml of ethylene glycol, and 2mL of concentrated ammonia water to make a slurry, stir in a water bath at 60°C for 1h, transfer it into an autoclave after the heat preservation is completed, and put it in a forced air drying oven for 36h at 140°C. After the reaction, the powder was filtered out, rinsed with deionized water and ethanol, and dried to obtain TiO 2 (B)g-C 3 N 4 Composite nanosheet photocatalyst, denoted as CNTO-2. Using methylene blue (MB) as the target degradation product, take TiO 2(B)g-C 3 N 4 Add 50 mg of composite nanosheet photocatalyst (CNTO-2) into 50 ml of MB solution with a concentration of 10 mg / L, ultrasonicat...

experiment example 3

[0028] Take 10g of urea and place it in a crucible, wrap the crucible tightly with aluminum foil, place it in a muffle furnace and calcinate at 550°C in an air atmosphere with a heating rate of 20°C / min, keep it warm for 4 hours and then cool it naturally, the obtained powder is g-C 3 N 4 . Take g-C 3 N 4 Powder 0.1g, with 1ml TiCl 4 , 35ml of ethylene glycol, and 2mL of concentrated ammonia water to make a slurry, stir in a water bath at 70°C for 1h, transfer it into an autoclave after the heat preservation is completed, and put it in a forced air drying oven for 24h at 150°C. After the reaction, the powder was filtered out, rinsed with deionized water and ethanol, and dried to obtain TiO 2 (B)g-C 3 N 4 Composite nanosheet photocatalyst, denoted as CNTO-3. Using methylene blue (MB) as the target degradation product, take TiO 2 (B)g-C 3 N 4 Add 50 mg of composite nanosheet photocatalyst (CNTO-3) into 50 ml of MB solution with a concentration of 10 mg / L, ultrasonicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com