Damage-free nanofabrication of single crystal silicon surface based on tribochemically induced etching

A nano-fabrication, single-crystal silicon technology, used in processes for producing decorative surface effects, gaseous chemical plating, metal material coating processes, etc., can solve the problem of poor etching resistance, limited depth/height, single crystal Silicon substrate damage and other problems, to achieve the effect of simple film forming process, avoiding friction loss, and convenient scanning center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A non-damage nanofabrication method on the surface of single crystal silicon based on tribochemically induced etching, the specific operation steps are as follows:

[0028] A, the mass concentration is 98% H 2 SO 4 solution and 30% H 2 o 2 The solution is mixed according to the volume ratio of 7:3 to obtain a mixed solution; the mixed solution is heated to 90°C; then the single crystal silicon that has been passivated by the HF solution is placed in the mixed solution for 30 minutes to make SiO grow on the surface x thin layer; then there will be grown SiO x The thin layer of monocrystalline silicon is taken out and cleaned;

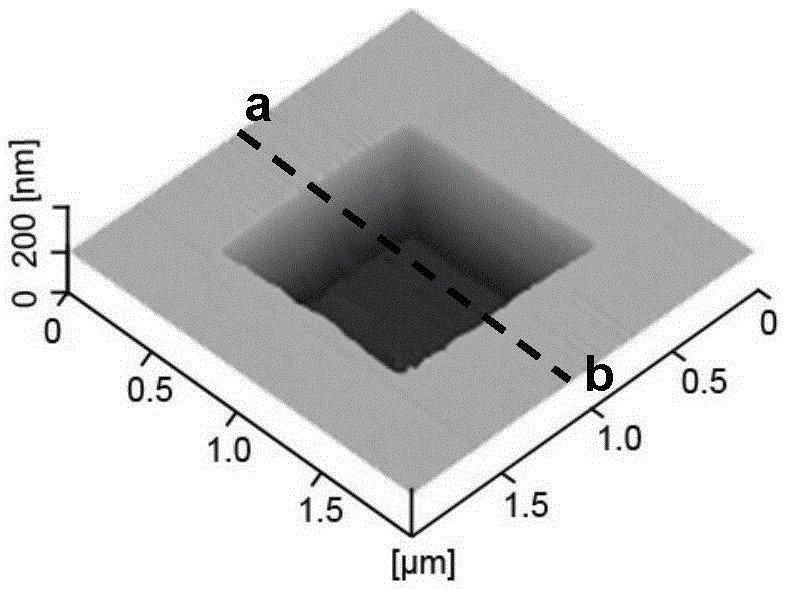

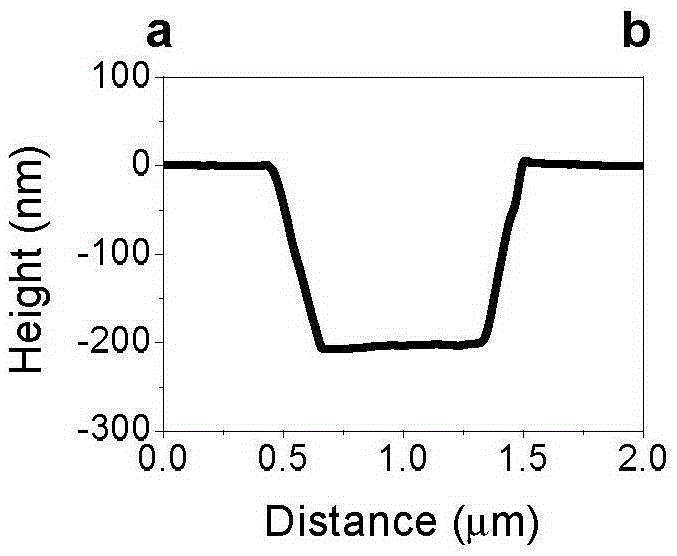

[0029] B. Install the silicon dioxide probe with a spherical tip on the scanning probe microscope, fix the single crystal silicon obtained in step A on the sample stage, start the scanning probe microscope, and control the probe with a contact pressure of 1GPa according to The surface scanning track of 2μm×2μm performs surface scanning on the...

Embodiment 2

[0033] A non-damage nanofabrication method on the surface of single crystal silicon based on tribochemically induced etching, the specific operation steps are as follows:

[0034] A, the mass concentration is 98% H 2 SO 4 solution and 30% H 2 o 2 The solution is mixed according to the volume ratio of 7:3 to obtain a mixed solution; the mixed solution is heated to 90°C; then the single crystal silicon that has been passivated by the HF solution is placed in the mixed solution for 30 minutes to make SiO grow on the surface x thin layer; then there will be grown SiO x The thin layer of monocrystalline silicon is taken out and cleaned;

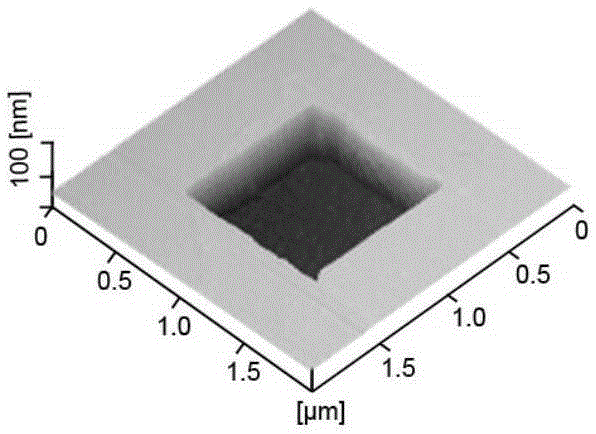

[0035] B. Install the silicon dioxide probe with a spherical tip on the scanning probe microscope, fix the single crystal silicon obtained in step A on the sample stage, start the scanning probe microscope, and control the probe with a contact pressure of 1GPa according to The surface scanning track of 2μm×2μm performs surface scanning on the...

Embodiment 3

[0039] A non-damage nanofabrication method on the surface of single crystal silicon based on tribochemically induced etching, the specific operation steps are as follows:

[0040] A, the mass concentration is 98% H 2 SO 4 solution and 30% H 2 o 2 The solution is mixed according to the volume ratio of 7:2 to obtain a mixed solution; the mixed solution is heated to 80°C; then the single crystal silicon that has been passivated by the HF solution is placed in the mixed solution for 25 minutes, so that SiO can grow on the surface x thin layer; then there will be grown SiO x The thin layer of monocrystalline silicon is taken out and cleaned;

[0041] B. Install the silicon dioxide probe with a spherical tip on the scanning probe microscope, fix the single crystal silicon obtained in step A on the sample stage, start the scanning probe microscope, and control the probe with a contact pressure of 1GPa according to The surface scanning track of 2μm×2μm performs surface scanning o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com