Simple nanometer magnesium oxide preparation method

A kind of nano-magnesium oxide, a simple technology, applied in the direction of magnesium oxide, nanotechnology, nanotechnology, etc., can solve the problem of whether the powder particle size is large or not, and achieve the effect of easy process control, uniform product particle size distribution, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

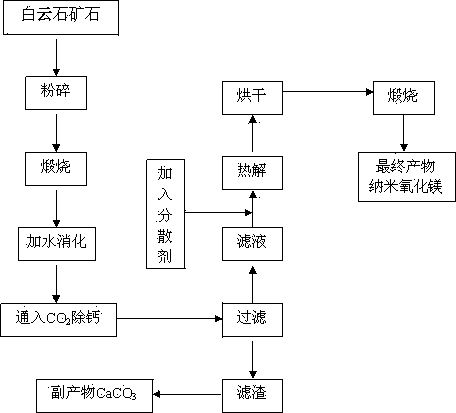

[0035] Take 1000g of crushed dolomite with a particle size of about 1-5mm, put it into a muffle furnace and calcinate at 950°C for 3 hours, grind it into powder after cooling, add 5 liters of distilled water to make a slurry, heat it to 60°C and keep Stirring was continued at this temperature for 50 minutes, and after cooling to room temperature, CO 2 gas, CO 2 The flow rate was 10 mL / min. When the slurry pH value is 7, stop feeding CO 2 Gas, the product is subjected to solid-liquid separation, and the collected liquid is magnesium bicarbonate solution (heavy magnesium water)①; Take 200mL of magnesium bicarbonate solution, add 0.3 g of dispersant polyethylene glycol 1000, stir thoroughly for 30 minutes, put Stand still and heat in a water bath at 80°C for 45 minutes, then filter and collect the solid product (that is, solid basic magnesium carbonate) ②; put the obtained solid product into a muffle furnace for calcination, the calcination temperature is controlled at 500°C, a...

Embodiment 2

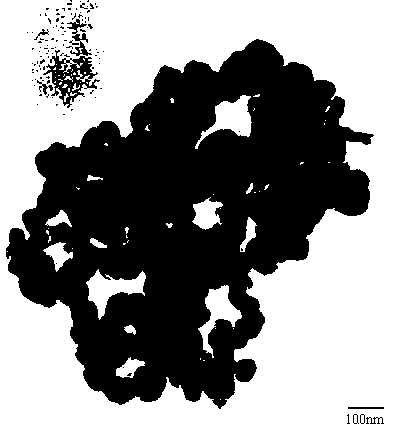

[0037]Take magnesium bicarbonate solution①100mL, add 0.3g of polyethylene glycol 200, stir thoroughly for 30 minutes, put it in a water bath at 80°C and heat it for 60 minutes, then filter and collect the solid product (basic magnesium carbonate); put the obtained solid product in Put it into a muffle furnace for calcination, the calcination temperature is controlled at 500° C., and the calcination time is 50 minutes to obtain a nano-magnesia product with an average particle size of 70 nm.

Embodiment 3

[0039] Take 200 mL of magnesium bicarbonate solution ①, add 0.3 g of polyethylene glycol 500, stir thoroughly for 30 minutes, put it in a water bath at 80°C and heat it for 50 minutes, then filter and collect the solid product (basic magnesium carbonate); put the obtained solid product in Put it into a muffle furnace for calcination, the calcination temperature is controlled at 500° C., and the calcination time is 40 minutes to obtain a nano-magnesia product with an average particle size of 60 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com