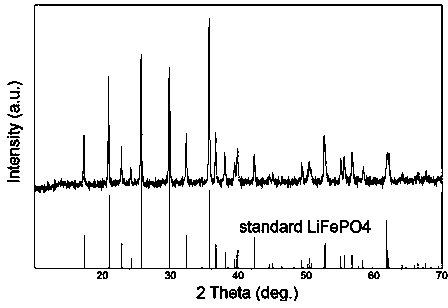

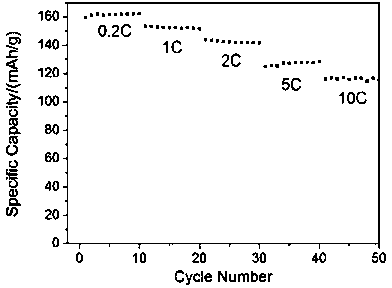

Method for preparing cell-grade lithium iron phosphate from pyrite slag

A technology of pyrite slag and lithium iron phosphate, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as difficult to effectively control impurities, high energy consumption, and ineffective leaching of iron elements, etc., and achieve reduction Low energy consumption, low water heating temperature and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing battery-grade lithium iron phosphate by utilizing pyrite slag, comprising the following steps:

[0030] (1) Import pyrite slag just out of the furnace at about 850°C into the rotary furnace, 2 / N 2 Reduction roasting under a mixed gas reducing atmosphere for 10 hours, H 2 / N 2 The flow rate of the mixed gas is controlled at 8 m 3 / hour, H 2 / N 2 H in the mixture 2 The volume fraction is 5%;

[0031] (2) Add 20% (mass concentration, the same below) sulfuric acid to the pyrite slag, the acid excess coefficient is 1.4 (based on the theoretical stoichiometric ratio of iron / sulfuric acid 1:1, the same below), and the temperature is 60°C , after stirring for 200 minutes, filter to obtain iron-containing leachate;

[0032] (3) Add enough iron nuggets to the leaching solution to consume excess sulfuric acid, and filter at a temperature of 50°C for 120 minutes; add 20% (mass, the same below) concentrated ammonia water to the further obtained leachi...

Embodiment 2

[0037] A method for preparing battery-grade lithium iron phosphate by utilizing pyrite slag, comprising the following steps:

[0038] (1) Import pyrite slag just out of the furnace at about 850°C into the rotary furnace, and add graphite accounting for 20wt% of the mass of pyrite slag as a reducing agent at the same time. 2 (N 2 The flow rate is controlled at 8 m 3 / hour) reduced roasting under the atmosphere for 30 minutes;

[0039] (2) Add 50% sulfuric acid to the pyrite slag, the acid excess coefficient is 1.3, the temperature is 70°C, stir for 100 minutes and then filter to obtain the iron-containing leachate;

[0040] (3) Add enough iron nuggets to the leaching solution to consume excess sulfuric acid, and filter at a temperature of 80°C for 60 minutes; add 25% concentrated ammonia water to the further obtained leaching solution to adjust the pH value to 3, and add ‰ anionic polyacrylamide for flocculation and precipitation (purchased from France Eisen Company), and t...

Embodiment 3

[0045] A method for preparing battery-grade lithium iron phosphate by utilizing pyrite slag, comprising the following steps:

[0046] (1) Import pyrite slag just out of the furnace at about 850°C into the rotary furnace, and add glucose accounting for 10% of the mass of pyrite slag as a reducing agent at the same time. 2 (N 2 The flow rate is controlled at 8 m 3 / hour) reduced roasting under the atmosphere for 60 minutes;

[0047] (2) Add 80% sulfuric acid to the pyrite slag, the acid excess coefficient is 1.2, the temperature is 80°C, and after stirring for 10 minutes, filter to obtain the iron-containing leachate;

[0048] (3) Add enough iron nuggets to the leaching solution to consume excess sulfuric acid at a temperature of 90°C, react for 30 minutes and then filter; in the further obtained leaching solution, add concentrated ammonia water with a concentration of 28% to adjust the pH value to 4, and add 20‰ of anionic polyacrylamide for flocculation and precipitation (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com