Novel gasoline and diesel hydrorefining supported catalyst as well as preparation method and application thereof

A supported catalyst, hydrorefining technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. High cost, low catalytic efficiency and other problems, to achieve the effect of reduced grain size, high catalytic efficiency, and increased hydrodesulfurization and hydrodenitrogenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Mo-Ni-Re Hydrotreating Supported Catalyst

[0024] The preparation method is as follows:

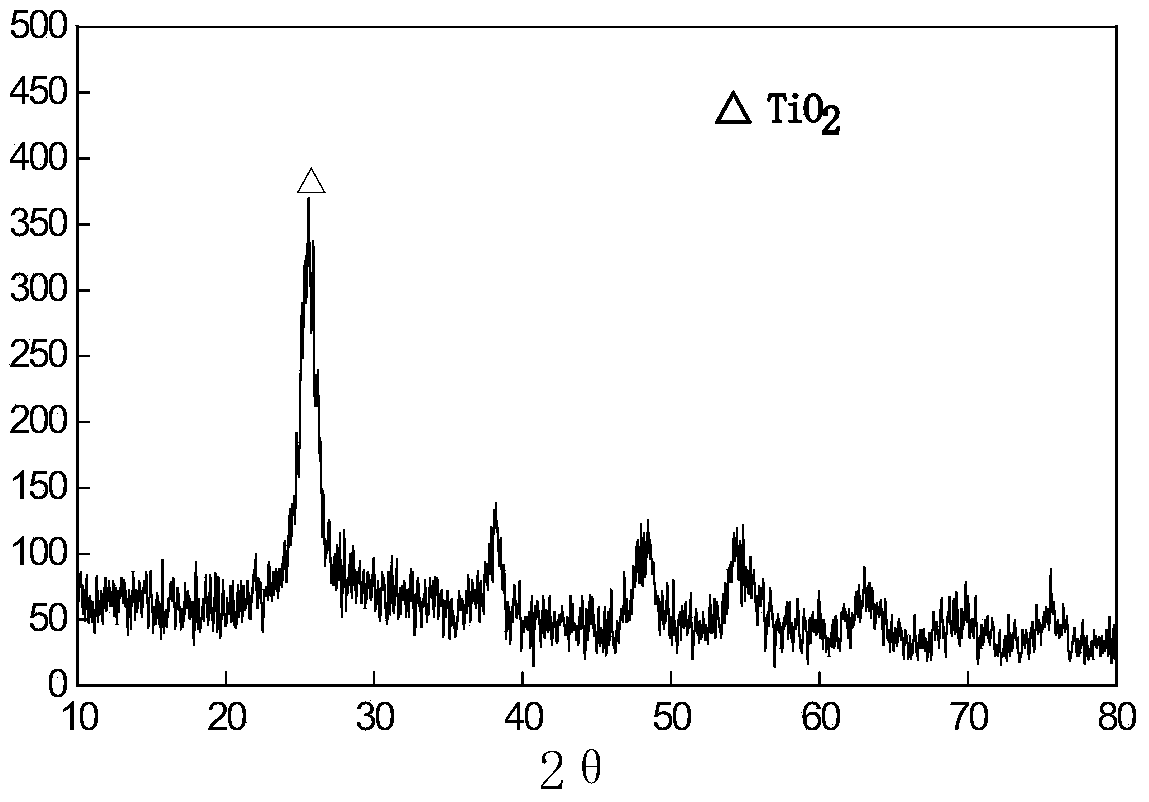

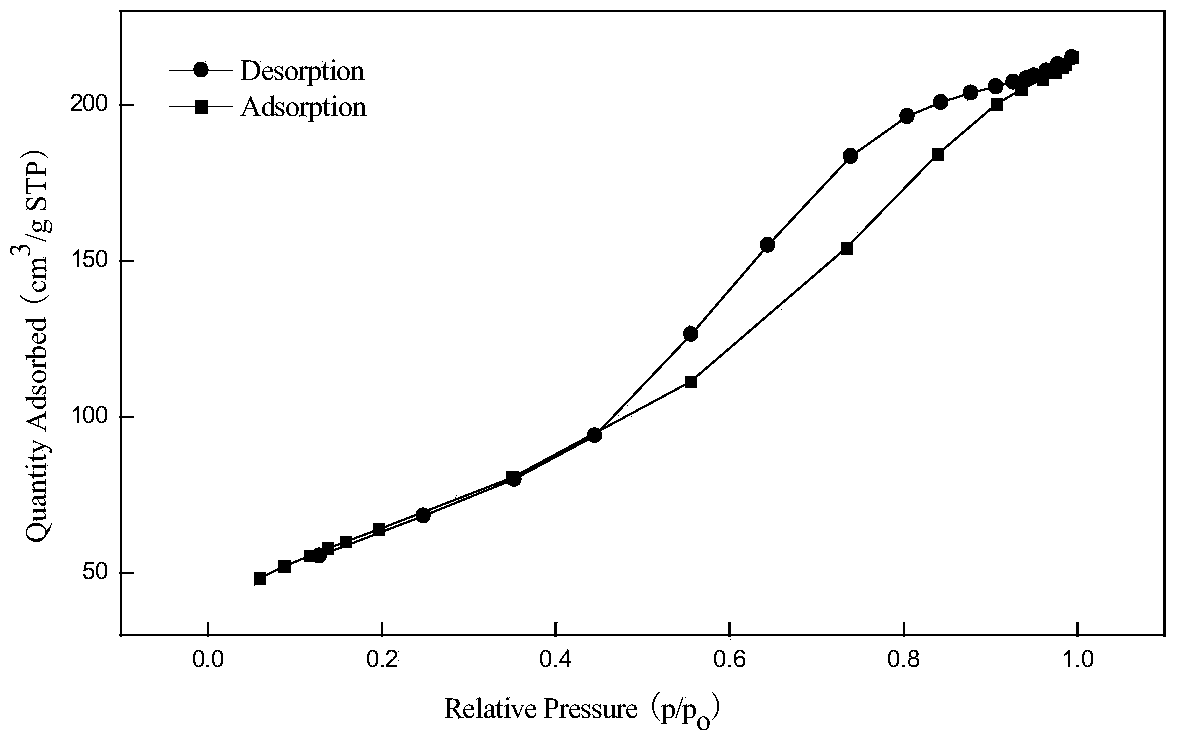

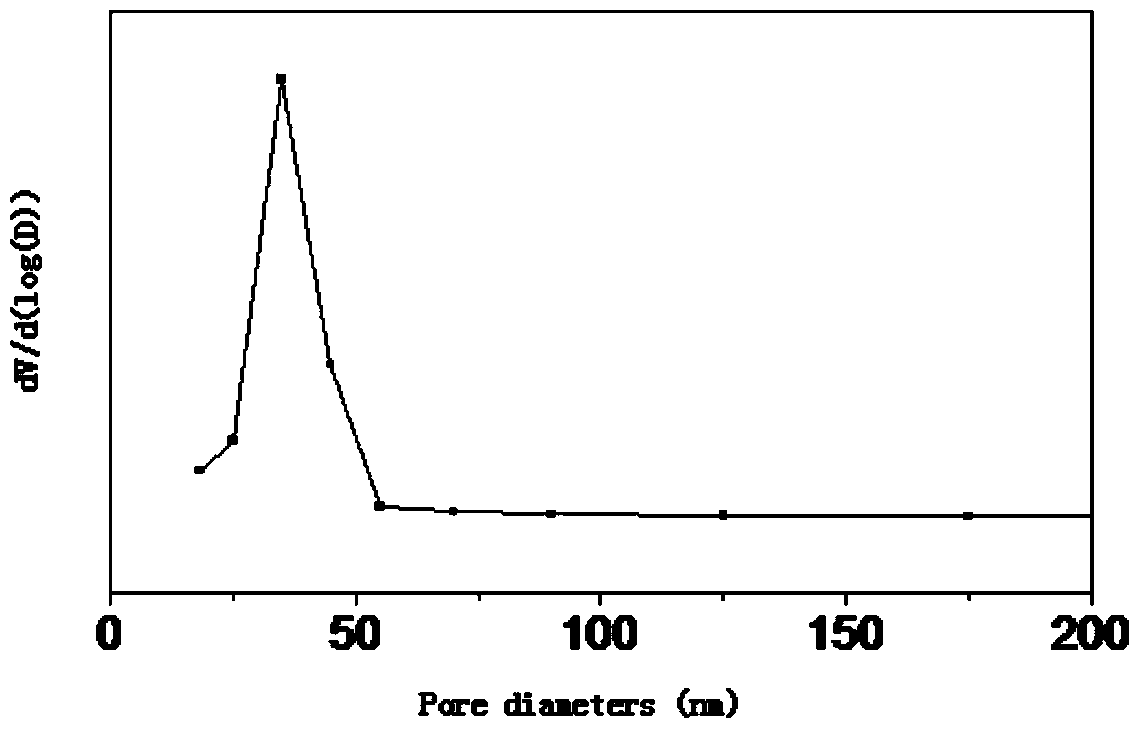

[0025] (1) SiO2 2 -TiO 2 -ZrO 2 Preparation of ternary oxide support:

[0026] 1) ZrOCl 2 ·8H 2 O was dissolved in absolute ethanol to obtain a clear and transparent solution A;

[0027] 2) Measure 30mL of TiCl in the fume hood 4 Put the solution into a separatory funnel, drop it dropwise into a beaker with absolute ethanol, stir evenly, then use a pipette to pipette 50mL of silica sol and drop it into the solution to obtain Ti-containing solution B;

[0028] 3) Put solution B into a separatory funnel and slowly add it dropwise to solution A above to obtain solution C;

[0029] 4) Dissolve the template agent polyethylene glycol-20000 in water, add ammonia water, adjust the pH to 8, and obtain solution D;

[0030] 5) Slowly add solution C to solution D to form a white flocculent precipitate;

[0031] 6) Seal the beaker with plastic wrap and let it stand at roo...

Embodiment 2

[0038] Example 2 Mo-Re Hydrofining Supported Catalyst

[0039] The preparation method is as follows:

[0040] (1) SiO2 2 -TiO 2 -ZrO 2 Preparation of ternary oxide carrier: the preparation method is the same as that in Example 1.

[0041] (2) Preparation of Hydrofining Supported Catalyst:

[0042] Weigh 5.00g carrier, 0.62g (NH 4 ) 6 Mo 7 .4H 2 O dissolved in water, 0.59g NH 4 ReO 4 Dissolved in boiling water, the ternary oxide support was sequentially impregnated in (NH 4 ) 6 Mo 7 .4H 2 O solution and NH 4 ReO 4 Immerse in the solution for 12 hours respectively, then dry at 120°C for 10 hours, and then in a muffle furnace at 550°C and constant temperature for 4 hours, to prepare a hydrogenation refined supported catalyst, crush and finely grind, and sieve to obtain 40-60 mesh particles. The molar ratio of active components in the catalyst is Mo:Re=3:2.

Embodiment 3

[0043] Example 3 Mo-Ni Hydrofining Supported Catalyst

[0044] (1) SiO2 2 -TiO 2 -ZrO 2 Preparation of ternary oxide carrier: the preparation method is the same as that in Example 1.

[0045] (2) Preparation of Hydrofining Supported Catalyst:

[0046] Weigh 5.00g carrier, 0.52g (NH 4 ) 6 Mo 7 .4H 2 O dissolved in water, 1.51g Ni(NO 3 ) 2 .6H 2 O was dissolved in water, and the ternary oxide support was sequentially impregnated in (NH 4 ) 6 Mo 7 .4H 2 O solution and Ni(NO 3 ) 2 .6H 2 Immerse in O solution for 12 hours respectively, then dry at 120°C for 10 hours, and then in a muffle furnace at 550°C and constant temperature for 4 hours, prepare a hydrorefining supported catalyst, pulverize, finely grind, and sieve to obtain 40-60 mesh particles , the molar ratio of active components in the catalyst is Mo:Ni=9:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com