Titanium dioxide for denitration catalyst and preparation method of titanium dioxide

A denitration catalyst, titanium dioxide technology, applied in the direction of catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problems of reducing the specific surface area of the catalyst, inactivating the catalyst, shortening the service life, etc., and reaching the temperature range suitable for denitration Wide, no pollutant emission, small production investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Grind 85 parts by weight of anatase titanium dioxide and 1 part by weight of α-molybdenum silicate in a vibrating mill for 20 minutes at a speed of 500 r / min. The particle size decreases, the specific surface area increases, and the Gibbs free energy increases, thereby promoting the occurrence of mechanochemical effects. The lattice modifier extends into the lattice on the surface of the anatase titanium dioxide particle, increasing the surface lattice gap;

[0038] 2) Mix the titanium dioxide microparticles obtained in step 1) with 10 parts by weight of polymethylcarbosilane and evenly send them into a twin-screw extruder for extrusion and granulation;

[0039] 3) The pellets obtained in step 2) were carbonized at 400° C. for 20 minutes to obtain fluffy titanium dioxide for denitration catalyst.

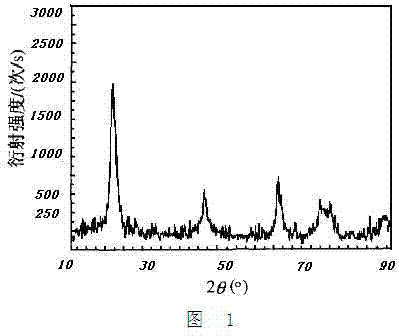

[0040] The obtained samples were calcined at 200°C, 500°C, 800°C, 1100°C, and 1300°C for 5 hours at high temperatures, and the changes in crystal phase structure and speci...

Embodiment 2

[0042] 1) Grind 90 parts by weight of anatase titanium dioxide and 2 parts by weight of aluminum phosphate in a vibratory mill for 15 minutes at a grinding speed of 400 r / min, and the grain size of anatase titanium dioxide decreases during the process of vibrating mill refinement , the specific surface area increases, and the Gibbs free energy increases, thereby promoting the occurrence of mechanochemical effects. The lattice modifier extends into the lattice on the surface of the anatase titanium dioxide particle, increasing the surface lattice gap;

[0043] 2) Mix the titanium dioxide particles obtained in step 1) with 8 parts by weight of polymethylethoxycarbosilane and evenly send them into a twin-screw extruder for extrusion and granulation;

[0044] 3) The pellets obtained in step 2) were carbonized at 300° C. for 20 minutes to obtain fluffy titanium dioxide for denitration catalyst.

Embodiment 3

[0046] 1) Grind 85 parts by weight of anatase titanium dioxide and 1 part by weight of bismuth phosphate in a vibratory mill for 10 minutes at a grinding speed of 450 r / min, and the grains of anatase titanium dioxide are reduced in the process of vibrating mill refinement , the specific surface area increases, and the Gibbs free energy increases, thereby promoting the occurrence of mechanochemical effects. The lattice modifier extends into the lattice on the surface of the anatase titanium dioxide particle, increasing the surface lattice gap;

[0047] 2) Mix the titanium dioxide microparticles obtained in step 1) with 5 parts by weight of polymethyltrifluoropropylcarbosilane and send them into a twin-screw extruder for extrusion and granulation;

[0048] 3) The pellets obtained in step 2) were carbonized at 350° C. for 20 minutes to obtain fluffy titanium dioxide for denitration catalyst.

[0049] The obtained sample was calcined at 800°C for 5 hours, and the BET specific surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap