Active oxygen free radical sensitive cyclodextrin material as drug delivery carrier and preparation method thereof

A delivery carrier and cyclodextrin technology, which is applied in the direction of non-active components of polymer compounds, can solve the problems of limitations and lack of materials, and achieve the effects of simple preparation methods, easy large-scale synthesis, and good in vivo biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

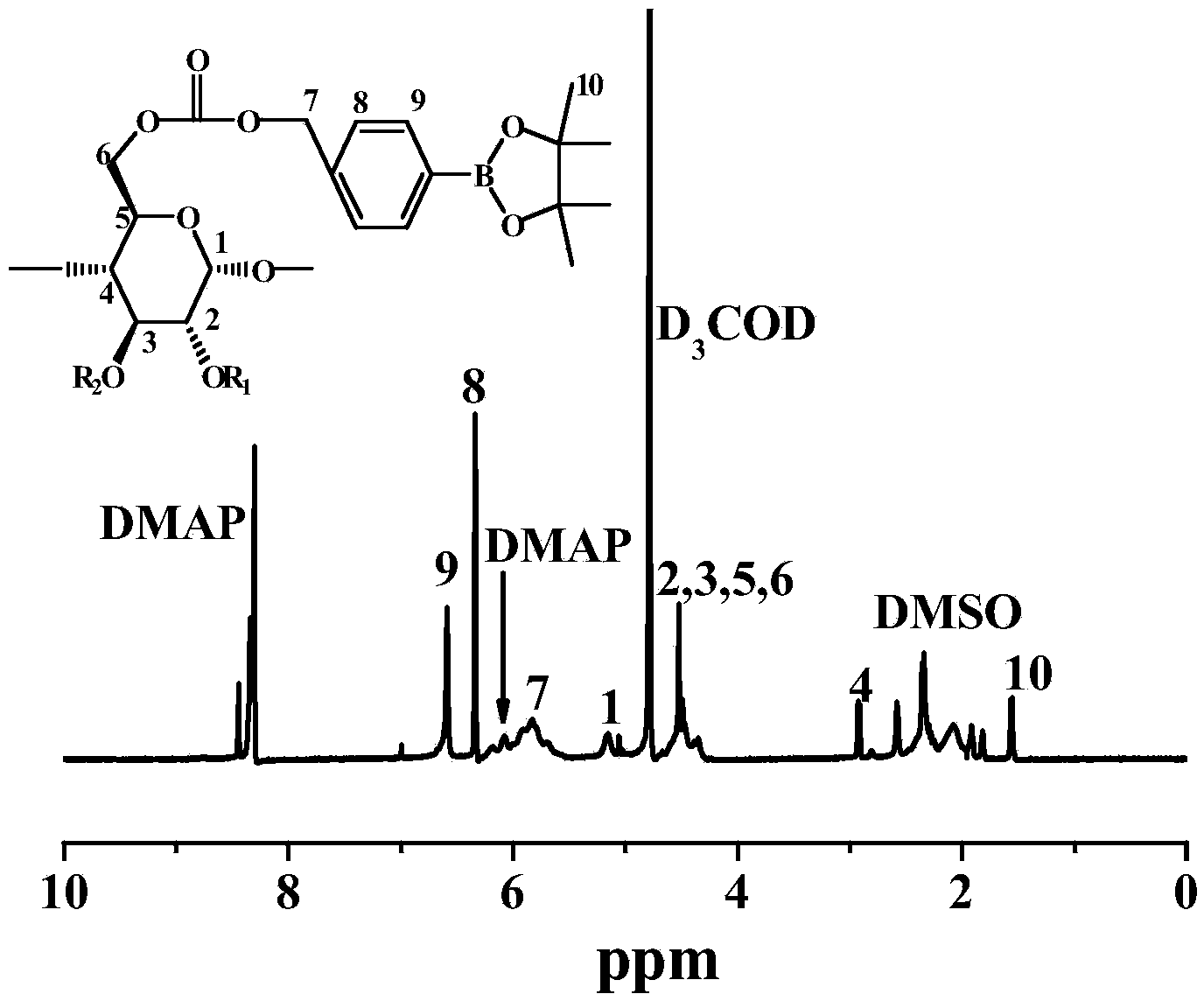

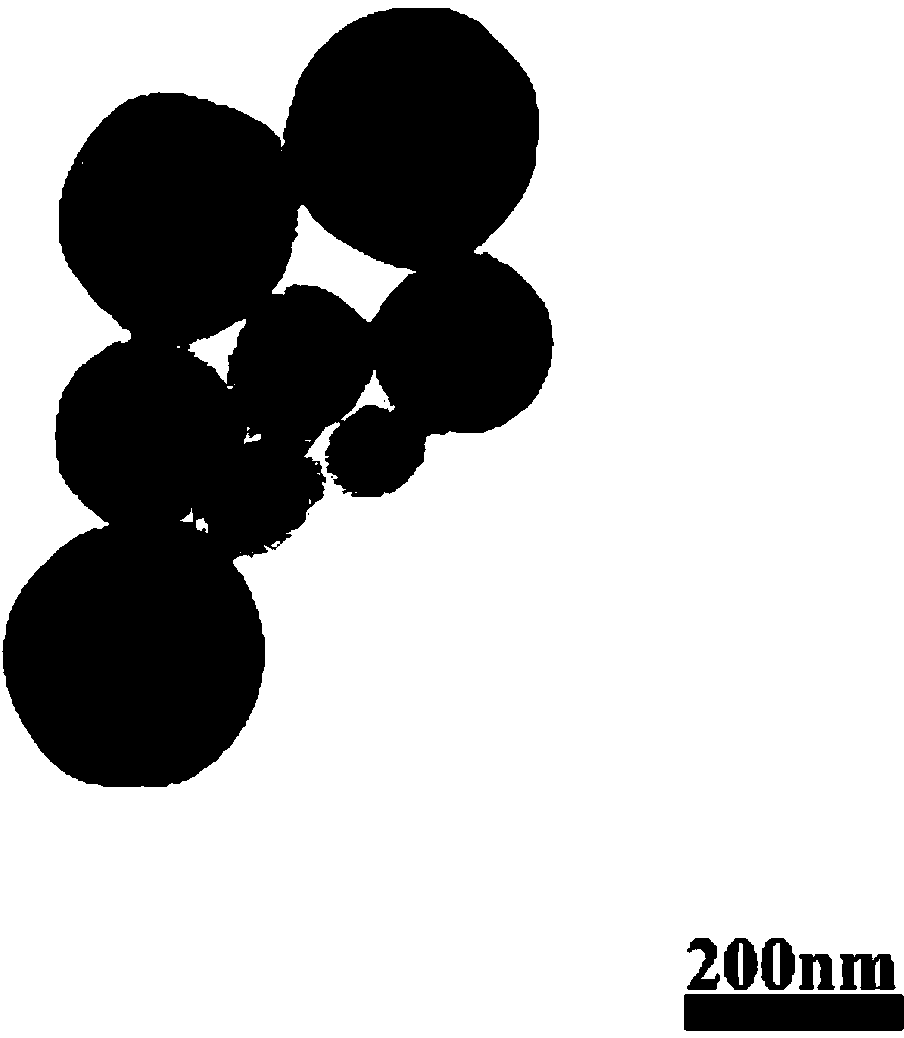

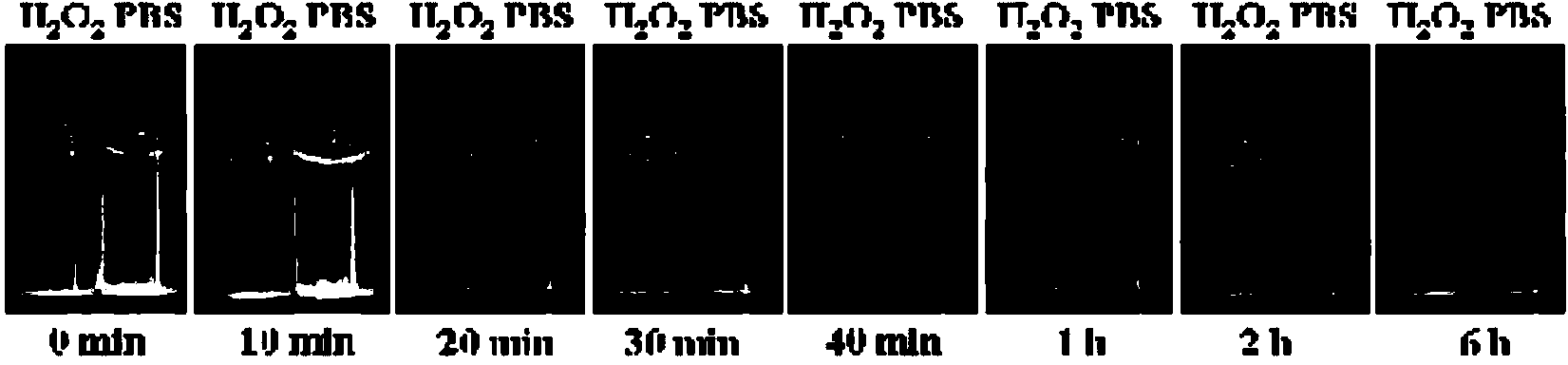

[0038] Under nitrogen protection, 10mmol3-hydroxymethylbenzeneboronic acid and 15mmol pinacol were reacted in 60mL anhydrous tetrahydrofuran to obtain 3-hydroxymethylphenylboronic acid pinacol ester; 5mmol3-hydroxymethylphenylboronic acid pinacol ester was mixed with 10mmol N , N'-carbonyldiimidazole was reacted in 20 mL of anhydrous chloroform to obtain 3-imidazole carbonyloxy-phenylboronic acid pinacol ester; in the presence of 4 mmol 4-dimethylaminopyridine, 0.3 mmol α-cyclodextrin and 4 mmol 3-imidazole Carbonyloxy-phenylboronic acid pinacol ester was reacted in 15 mL of dimethyl sulfoxide at 20° C., and after 8 hours, the cyclodextrin material was obtained by precipitation in water, collected by centrifugation, and dried.

Embodiment 2

[0040] Under nitrogen protection, 10mmol 4-hydroxymethylbenzeneboronic acid and 20mmol pinacol were reacted in 50mL anhydrous dioxane to obtain 4-hydroxymethylphenylboronic acid pinacol ester; 5mmol4-hydroxymethylphenylboronic acid pinacol ester React with 15mmol N,N'-carbonyldiimidazole in 30mL of anhydrous dichloromethane to obtain 4-imidazole carbonyloxy-phenylboronic acid pinacol ester; in the presence of 4mmol N,N'-dicyclohexylcarbodiimide, 0.15mmol of β-cyclodextrin and 4mmol of 4-imidazolecarbonyloxy-phenylboronic acid pinacol ester were reacted in 12mL N,N-dimethylformamide at 30°C, and after 12 hours, they were collected by precipitation in water and centrifugation , and drying to obtain cyclodextrin material.

Embodiment 3

[0042]Under nitrogen protection, 10mmol3-hydroxymethylbenzeneboronic acid and 25mmol pinacol react in 60mL anhydrous acetonitrile to obtain 3-hydroxymethylphenylboronic acid pinacol ester; 8mmol3-hydroxymethylphenylboronic acid pinacol ester and 20mmol N , N'-carbonyldiimidazole was reacted in 25 mL of anhydrous ethyl acetate to obtain 3-imidazole carbonyloxy-phenylboronic acid pinacol ester; in the presence of 4.8 mmol N, N'-diisopropylcarbodiimide, 0.1 One mmol of γ-cyclodextrin reacted with 4.8 mmol of 3-imidazolecarbonyloxy-phenylboronic acid pinacol ester in 10 mL of N,N-dimethylacetamide at 40°C, and after 24 hours, it was collected by precipitation in water and centrifugation , and drying to obtain cyclodextrin material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com