Method for detecting content of urea in brewed wine by using high performance liquid chromatography

A technology of high performance liquid chromatography and urea content, which is applied in the field of detection of urea content in fermented wine, can solve the problems of instability, high level requirements, increased colorimetric measurement error, etc., and achieves high recovery rate and simple processing method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

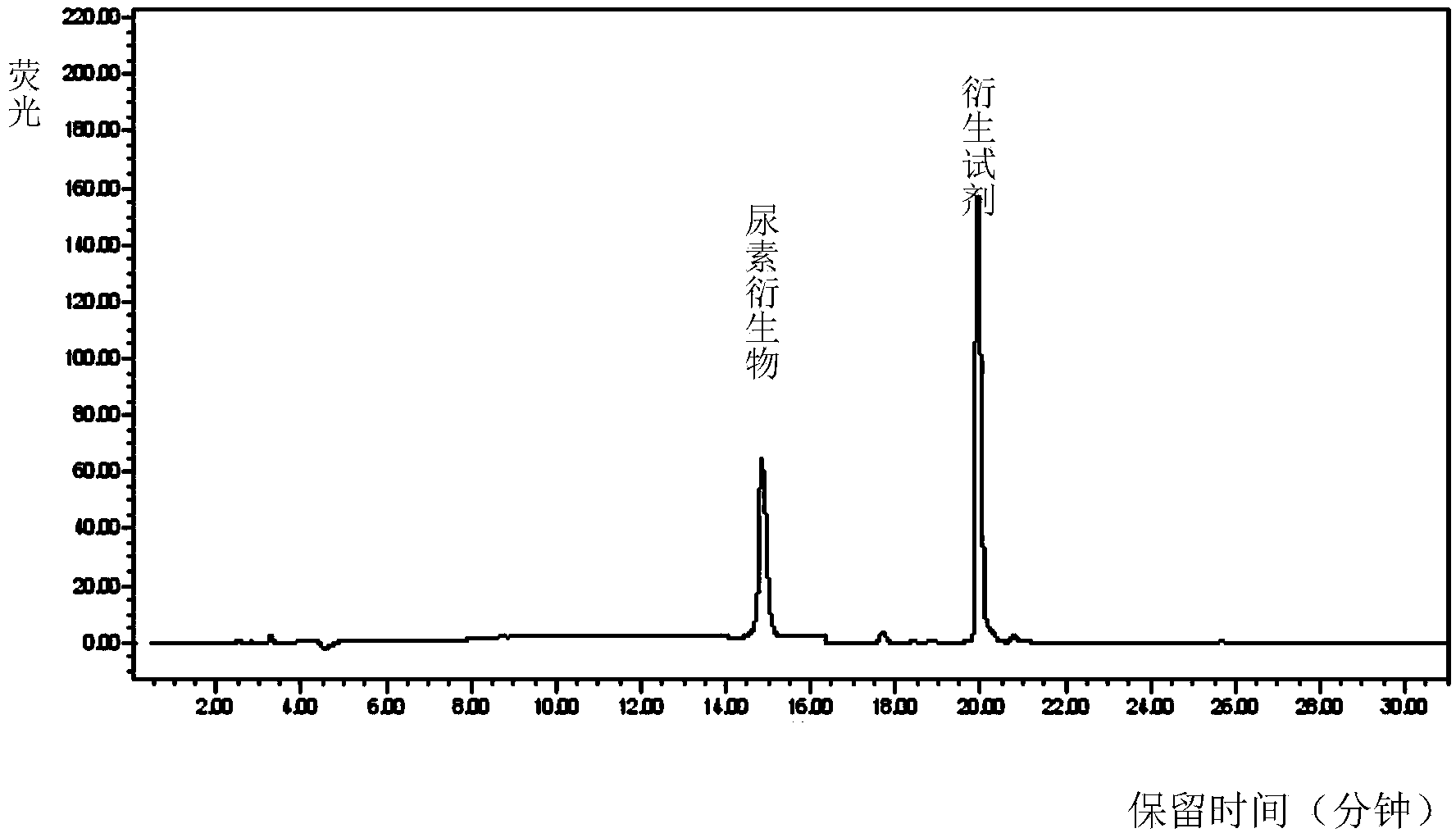

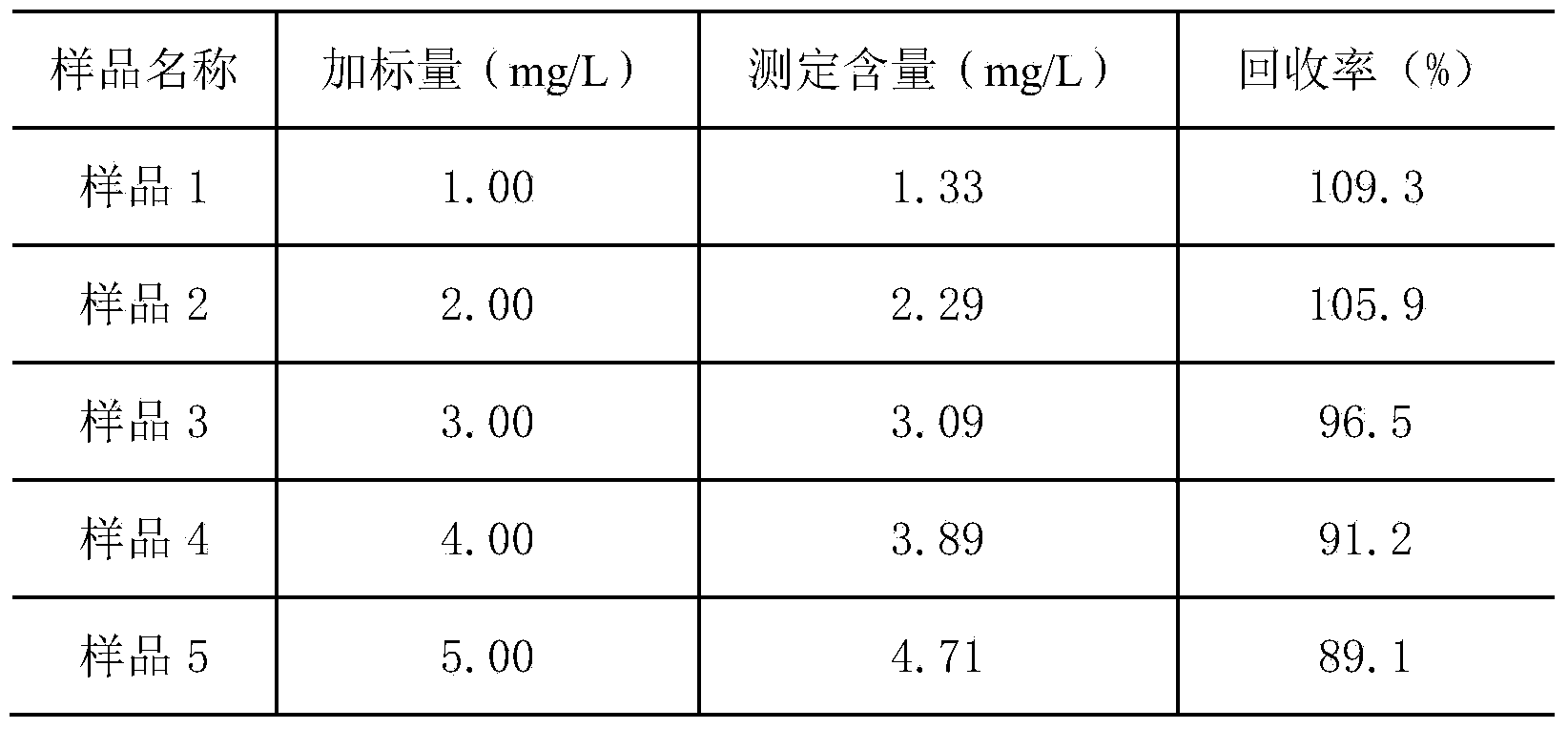

[0028] Accurately draw 2.0mL of the sample, put it in a 10mL volumetric flask, and dilute to the mark with absolute ethanol. Take 2 mL of the diluted sample solution and place it in a test tube with a stopper, add 0.5 mL of hydrochloric acid solution (concentration: 1.5 mol / L) and 2 mL of 9-hydroxyzanthene solution (concentration: 0.03 mol / L), mix well, and place it at room temperature in the dark The derivatization was carried out under the condition of 30min. Do this three times, combine the derivatized solution into a 100mL round bottom flask, concentrate the solution to about 5mL by a rotary evaporator to form a concentrated solution, transfer the concentrated solution to a 10mL volumetric flask, dilute to the mark with ethanol, pass 0.45 um organic filter membrane to form a pre-treated solution to be tested for liquid chromatography testing. Five parallel samples were made for the sample. According to the derivation method, the fermented wine sample was derivatized by ad...

Embodiment 2

[0032] Derivative time is set as 50min, other conditions are the same as embodiment 1, the relative standard deviation of gained parallel sample<8%, the relative standard deviation of repeatability test<5%, the standard addition recovery rate of sample is between 85%-110%. between.

Embodiment 3

[0034] Column temperature is set as 40 ℃, and other conditions are the same as embodiment 1, and the result peak time slightly changes, and other is constant, the relative standard deviation of gained parallel sample<8%, the relative standard deviation<5% of repeatability test, The spiked recoveries of the samples ranged from 85% to 110%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com