Titanium/aluminum solid-liquid composite casting forming method

A technology of casting molding and solid-liquid compounding, which is applied in the field of material processing engineering, can solve the problems of many cracks and holes, thick interface reaction layer, complex process, etc., and achieve the effect of high bonding strength and few defects such as cracks and holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

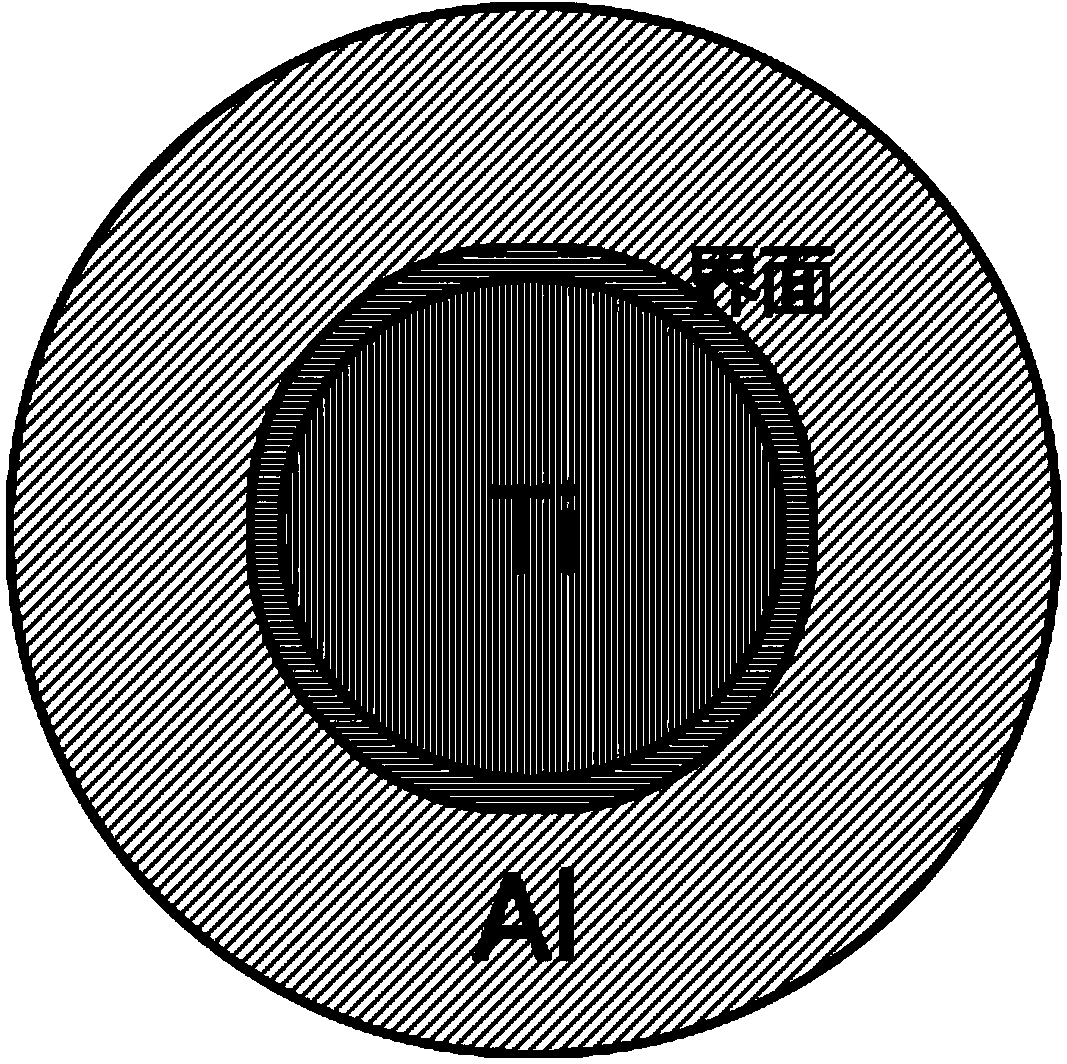

Image

Examples

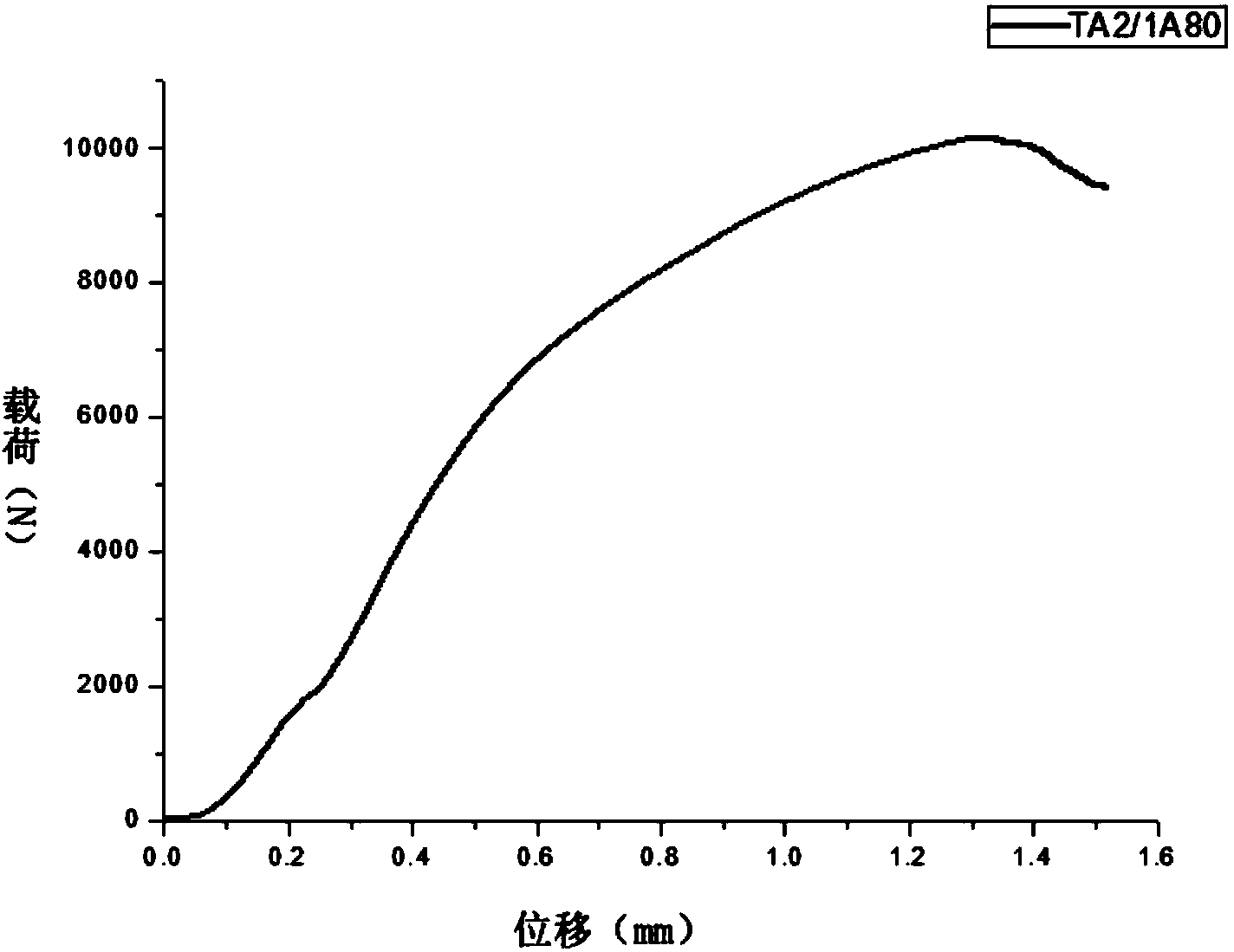

Embodiment 1

[0031] Embodiment 1: pure titanium / pure aluminum composite casting

[0032] Grade and composition of industrial pure titanium:

[0033] TA2 Industrial pure titanium, mass fraction: Fe≤0.3%, C≤0.08%, H≤0.015%, O≤0.25%, N≤0.03%, other elements ≤0.10% and total ≤0.40%, the rest is Ti.

[0034] Industrial pure aluminum grade and composition:

[0035] 1A80 industrial pure aluminum, its mass fraction: containing Si≤0.15%, Fe≤0.15%, Cu≤0.03%, Mn≤0.02%, Mg≤0.02%, Zn≤0.03%, Ca≤0.03%, V≤0.05%, Ti≤0.03%, other elements≤0.02%, and the rest is Al.

[0036] Specific steps:

[0037](1) Mechanically treat and chemically clean the surface of the TA2 titanium rod with a size of Φ6×60mm (6mm in diameter and 60mm in length) after machining to remove oil and oxides on the surface. The mechanical treatment is to grind with 400#, 600#, 800#, 1000#, 1500#, 2000# sandpaper in order to obtain the required roughness on the surface of the titanium rod; the chemical cleaning is to use 5% NaOH solution...

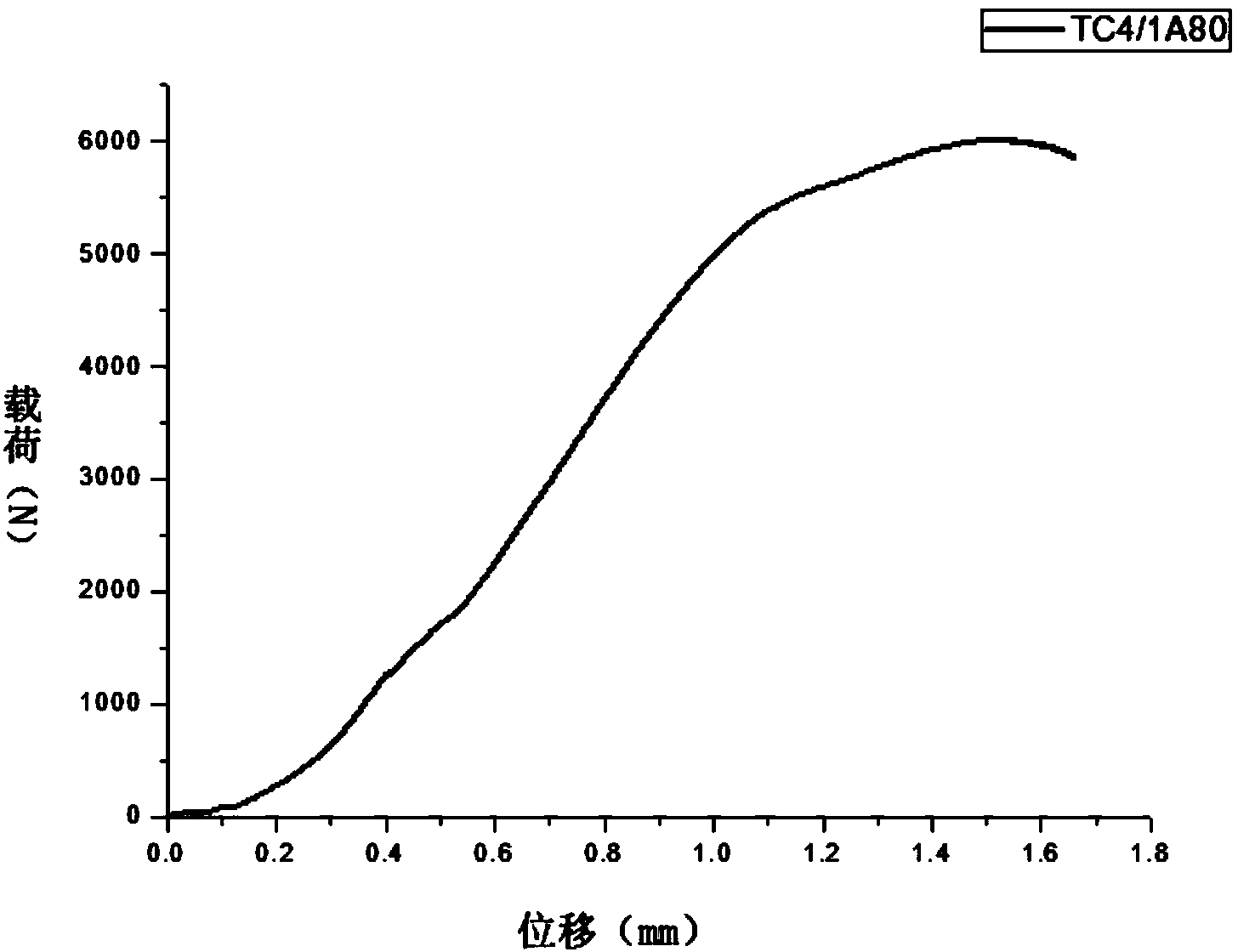

Embodiment 2

[0042] Embodiment 2: Titanium alloy / pure aluminum composite casting

[0043] Titanium alloy grade and composition:

[0044] TC4 (Ti-6Al-4V) titanium alloy, its mass fraction: Al5.5-6.75%, V3.5%-4.5%, Fe≤0.30%, C≤0.08%, H≤0.015%, O≤0.20%, N ≤ 0.05%, other elements ≤ 0.10% and the total ≤ 0.40%, the rest is Ti.

[0045] Grade and composition of industrial pure aluminum:

[0046] 1A80 industrial pure aluminum, its mass fraction: containing Si≤0.15%, Fe≤0.15%, Cu≤0.03%, Mn≤0.02%, Mg≤0.02%, Zn≤0.03%, Ca≤0.03%, V≤0.05%, Ti≤0.03%, other elements≤0.02%, and the rest is Al.

[0047] Specific steps:

[0048] (1) Mechanically treat and chemically clean the surface of the TC4 titanium alloy rod with a size of Φ6×60mm (6mm in diameter and 60mm in length) after machining to remove oil and oxides on the surface. The mechanical treatment is to grind with 400#, 600#, 800#, 1000#, 1500#, 2000# sandpaper in order to obtain the required roughness on the surface of the titanium alloy rod; the...

Embodiment 3

[0053] Embodiment 3: titanium alloy / aluminum alloy composite casting

[0054] Titanium alloy grade and composition:

[0055] TC4 (Ti-6Al-4V) titanium alloy, its mass fraction: Al5.5-6.75%, V3.5%-4.5%, Fe≤0.30%, C≤0.08%, H≤0.015%, O≤0.20%, N ≤ 0.05%, other elements ≤ 0.10% and the total ≤ 0.40%, the rest is Ti.

[0056] Aluminum alloy grade and composition:

[0057] 7050 aluminum alloy, its mass fraction: containing Zn5.7%-6.7%, Cu2.0%-2.6%, Mg1.9%-2.6%, Zr0.08%-0.15%, Si≤0.12%, Fe≤0.15% , Cr ≤ 0.04%, Mn ≤ 0.10%, Ti ≤ 0.06%, other elements ≤ 0.05% and the total ≤ 0.15%, the rest is Al.

[0058] Specific steps:

[0059] (1) Mechanically treat and chemically clean the surface of the TC4 titanium alloy rod with a size of Φ6×60mm (6mm in diameter and 60mm in length) after machining to remove oil and oxides on the surface. The mechanical treatment is to grind with 400#, 600#, 800#, 1000#, 1500#, 2000# sandpaper in order to obtain the required roughness on the surface of the tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com