Fluorene-benzodi(benzothiadiazole) containing copolymer, preparation method and application thereof

A benzothiadiazole and copolymer technology is applied in the field of fluorene-benzodipolymer and its preparation, which can solve the problems of low energy conversion efficiency and the like, and achieve good thermal stability, good electron transport properties, and good performance. membranous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

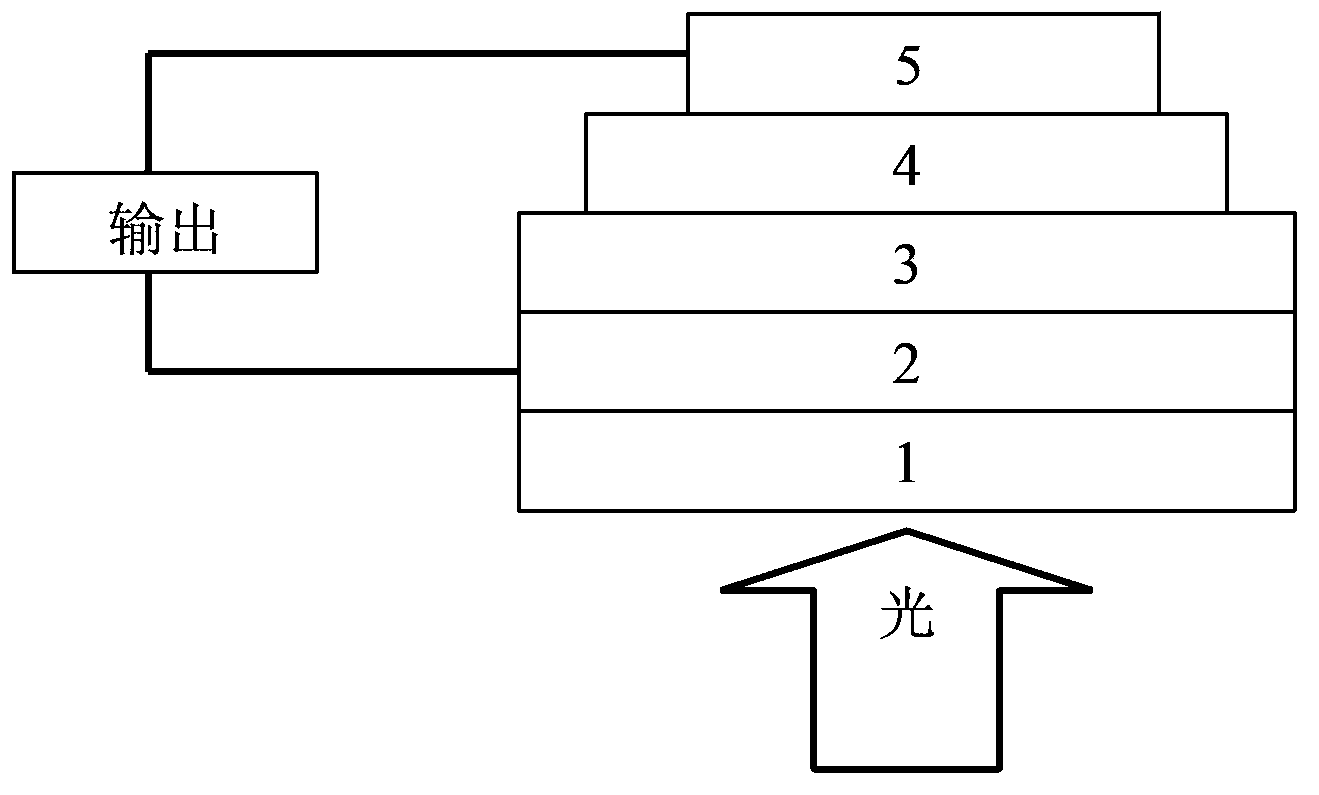

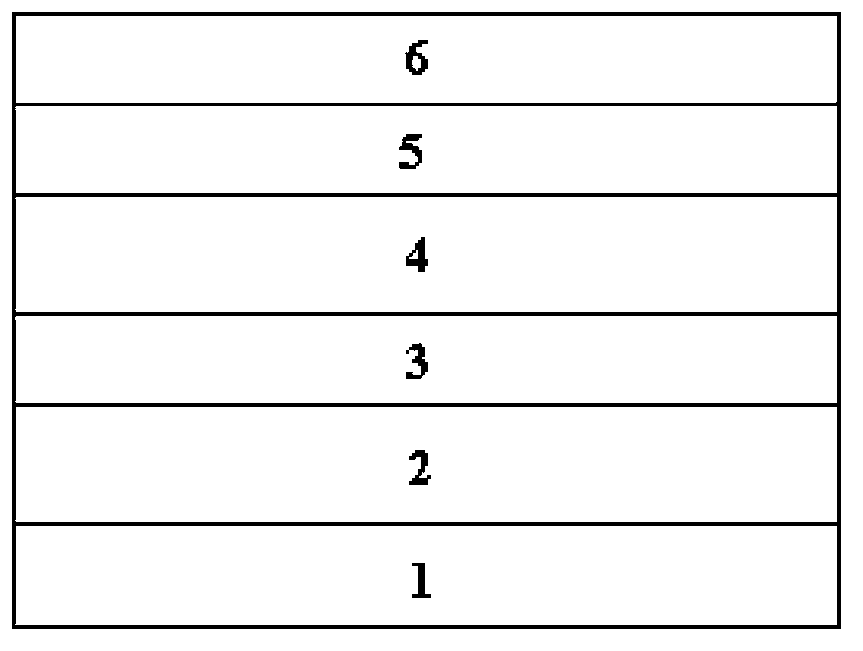

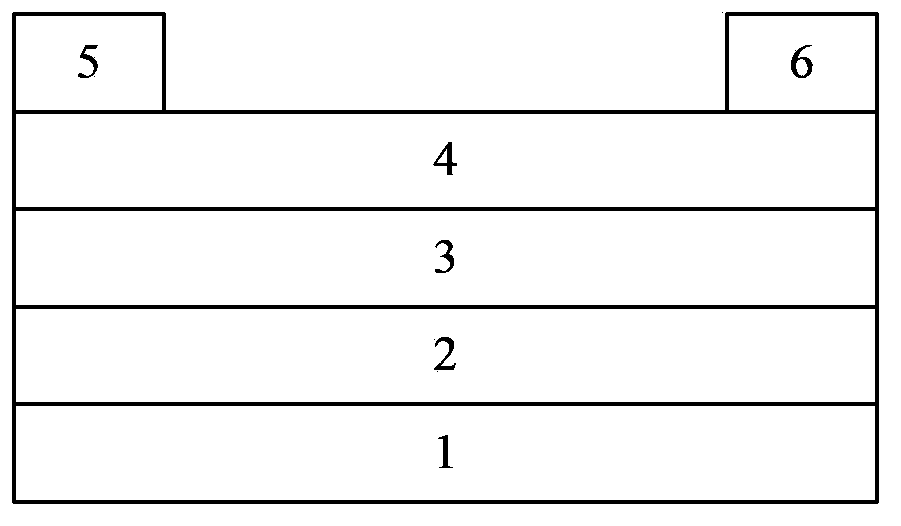

[0062] A fluorene-benzobis(benzothiadiazole) copolymer, that is, poly{9,9-di-n-octylfluorene-6,7-bis(3,7-dimethyloctyl)-benzo [2,1-e:3,4-e]bis(benzothiadiazole)} (n=48), denoted as copolymer P1, the structural formula is as follows:

[0063]

[0064] The preparation method comprises the following steps:

[0065] (1) The preparation method of 4,9-dibromo-6,7-dioctyl-benzo[2,1-e:3,4-e]bis(benzothiadiazole) (A1) is as follows:

[0066]

[0067] (1) Preparation of compound 5-nitro-2,1,3 benzothiadiazole, the reaction formula is:

[0068]

[0069] Add 4-nitrobenzene-1,2-diamine (22.95g, 0.15mol) and 100mL thionyl chloride into a three-necked flask, stir and slowly add 2mL pyridine dropwise, at room temperature 4-nitrobenzene-1, The 2-diamine is not completely dissolved, and the solution is orange. After heating, reflux reaction at 80~90°C for 24 hours, stop the reaction, heat to 80°C and rotate to evaporate excess thionyl chloride, then cool the reaction product to room ...

Embodiment 2

[0095] A fluorene-benzobis(benzothiadiazole) copolymer, namely poly{9,9-di(n-dodecyl)fluorene-6-(3,7-dimethyl)octyl-7 -Hexacyl-benzo[2,1-e:3,4-e]bis(benzothiadiazole)} (n=84), denoted as copolymer P2, the structural formula is as follows:

[0096]

[0097] The preparation method comprises the following steps:

[0098] (1), 4,9-dibromo-6-(3,7-dimethyl)octyl-7-hexadecyl-benzo[2,1-e:3,4-e]bis( Benzothiadiazole) (A2) is prepared as follows:

[0099] 4,4'-dibromo-6,6'-diiodo-bi-2,1,3-benzothiadiazole was prepared according to steps (1)-(4) of step (1) of Example 1.

[0100] A compound C2 having a structural formula as shown in formula C2 is provided, namely 2,6-dimethyl-11-hexahexyne.

[0101] Add 4,4'-dibromo-6,6'-diiodo-bi2,1,3-benzothiadiazole (3.4 g, 5 mmol), compound C2 (3.07 g, 10 mmol) and 25 mL of DMF in a three-necked flask , and stirred for 20min with nitrogen gas, then added Bu 3 N (0.907g, 10mmol) and Pd(OAc) 2 (115mg, 0.5mmol), heated to 130°C, reacted at cons...

Embodiment 3

[0114] A kind of fluorene-benzobis(benzothiadiazole) copolymer, that is, poly{fluorene-6-methyl-7-ethyl-benzo[2,1-e:3,4-e]bis( benzothiadiazole)} (n=10), denoted as copolymer P3, the structural formula is as follows:

[0115]

[0116] The preparation method comprises the following steps:

[0117] (1) Preparation of 4,9-dibromo-6-methyl-7-ethyl-benzo[2,1-e:3,4-e]bis(benzothiadiazole) (A3), method as follows:

[0118] 4,4'-dibromo-6,6'-diiodo-bi-2,1,3-benzothiadiazole was prepared according to steps (1)-(4) of step (1) of Example 1.

[0119] Compound C3, ie, 2-pentyne, having the structural formula shown in formula C3 is provided.

[0120] Add 4,4'-dibromo-6,6'-diiodo-bi2,1,3-benzothiadiazole (3.4 g, 5 mmol), compound C3 (0.68 g, 10 mmol) and 25 mL of DMF into a three-necked flask , and stirred for 20min with nitrogen gas, then added Bu 3 N (0.907g, 10mmol) and Pd(OAc) 2 (115mg, 0.5mmol), heated to 130°C, reacted at constant temperature for 4h, cooled, washed with water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com