Silane surface treating agent and preparation method thereof

A technology of silane surface treatment and silane coupling agent, applied in the field of silane surface treatment agent and its preparation, can solve the problems of inability to form a dense film layer, decreased customer satisfaction, low solubility of magnesium carbonate, etc. The effect of saving heating energy and fast film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

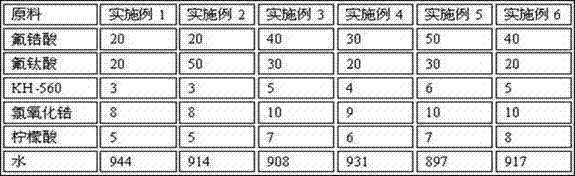

[0057] Every 1000Kg silane surface treatment agent is made of the following raw materials:

[0058] Fluorozirconic acid 20Kg, fluotitanic acid 20 Kg, silane coupling agent (KH-560) 3 Kg, zirconium oxychloride 8 Kg, citric acid 5 Kg, water 944 Kg.

[0059] Its preparation method comprises the following steps in turn:

[0060] (1) Add water to the reactor;

[0061] (2) Add silane coupling agent into the reaction kettle and stir until the silane coupling agent is completely hydrolyzed, and the stirring time is 7-9 hours;

[0062] (3) Add fluozirconic acid and fluotitanic acid into the reaction kettle, stir evenly and make the solution clear, and the stirring time is 0.5-1.5 hours;

[0063] (4) Add zirconium oxychloride to the reaction kettle, stir evenly and make the solution clear, and the stirring time is 0.5-1.5 hours;

[0064] (5) Add citric acid into the reaction kettle, stir well and make the solution clear, and the stirring time is 20-40 minutes.

[0065] (6) Check the...

Embodiment 2

[0068] Every 1000Kg silane surface treatment agent is made of the following raw materials:

[0069] Fluorozirconic acid 20Kg, fluotitanic acid 50Kg, silane coupling agent (KH-560) 3Kg, zirconium oxychloride 8Kg, citric acid 5Kg, water 914Kg.

[0070] The preparation method is the same as in Example 1.

[0071]

Embodiment 3

[0073] Every 1000Kg silane surface treatment agent is made of the following raw materials:

[0074] Fluorozirconic acid 40Kg, fluotitanic acid 30Kg, silane coupling agent (KH-560) 5Kg, zirconium oxychloride 10Kg, citric acid 7Kg, water 908Kg.

[0075] The preparation method is the same as in Example 1.

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com