Method for cultivating high density Thiobacillusdenitrificans

A high-density Thiobacillus denitrification technology, applied in the field of bioengineering, can solve the problems of long biological cultivation time, difficult and dangerous operation, single domestication method, etc., and achieve the effect of rich strains, rapid start-up, and diversified domestication methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

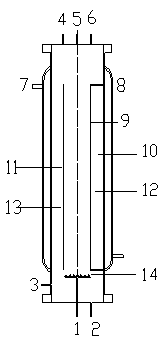

Method used

Image

Examples

Embodiment 1

[0028] Prepare the required nutrient solution according to the formula, put it into a triangular flask, wrap it, put it in a steam sterilizer, and carry out high-pressure moist heat sterilization, at 121°C~123°C, 0.12 MPa, sterilize for 20~30 min, take it out and cool it to room temperature.

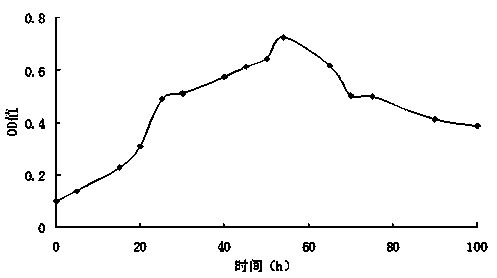

[0029] Using the above sterilized nutrient solution, with S 2 o 3 2- For energy, the temperature is 30 ℃, pH=7, the inoculation amount of Thiobacillus denitrificans is 10%, and the culture is carried out at 0 h, 5 h, 15 h, 20 h, 25 h, 30 h, 40 h, 45 h , 50 h, 55h, 65h, 70 h, 75 h, 90 h, 100 h sampling test OD 420 , with non-inoculated nutrient solution as a control.

[0030] test results figure 2 It shows that Thiobacillus denitrificans grows rapidly, maintains in the lag phase within 15 h, and the number of bacteria increases slightly, and then the bacteria enter the logarithmic growth phase, at this stage (15 h~30 h), the bacteria grow actively and reproduce in large numbers . ...

Embodiment 2

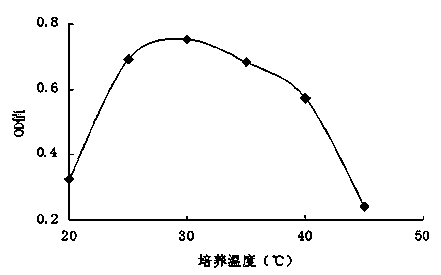

[0032] Using the above sterilized nutrient solution, with S 2 o 3 2- For energy, the inoculum amount of Thiobacillus denitrificans is 10%, pH=7, cultured in the temperature range of 20~40℃, and samples are taken to measure OD 420 , with non-inoculated nutrient solution as a control.

[0033] test results image 3It shows that the optimal growth temperature of Thiobacillus denitrificans is 25~35℃, and 30℃ is the most suitable growth temperature of Thiobacillus denitrificans. The growth of Thiobacillus denitrificans was significantly inhibited when the culture temperature was lower than 25℃; the growth of Thiobacillus denitrificans was significantly inhibited when the culture temperature was higher than 40℃.

Embodiment 3

[0035] Using the above sterilized nutrient solution, with S 2 o 3 2- For energy, the temperature is 30 ℃, the inoculum amount of Thiobacillus denitrificans is 10%, and the cultures are carried out in the range of pH=3~11, and the samples are taken to measure the OD 420 , with non-inoculated nutrient solution as a control.

[0036] test results Figure 4 It shows that when the pH value of Thiobacillus denitrificans is 5~9, especially in the range of 6~8, the OD value of the strain can be maintained at a relatively high concentration, which is because the optimum growth pH range of Thiobacillus denitrificans is 6~8, and partial acidity or partial alkalinity will inhibit the growth of Thiobacillus denitrificans.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com