Method for improving the shape of side wall of through hole

A top-notch morphology technology, applied in the field of improving the sidewall morphology of through holes, can solve the problems of increasing the difficulty of through hole etching process, increasing the processing cost, leakage of through silicon via products, etc., achieving slow lateral etching rate, Good anisotropy, the effect of reducing the difficulty of the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention provides a method for improving the morphology of the side wall of the through hole. The method of the invention does not need to alternate the etching step and the deposition step. By adding a gas that reacts with silicon to form a passivation layer in the etching gas, The sidewall of the through hole is protected while the through hole is etched.

[0021] The method for improving the morphology of the sidewall of the through hole described in this embodiment includes the following steps:

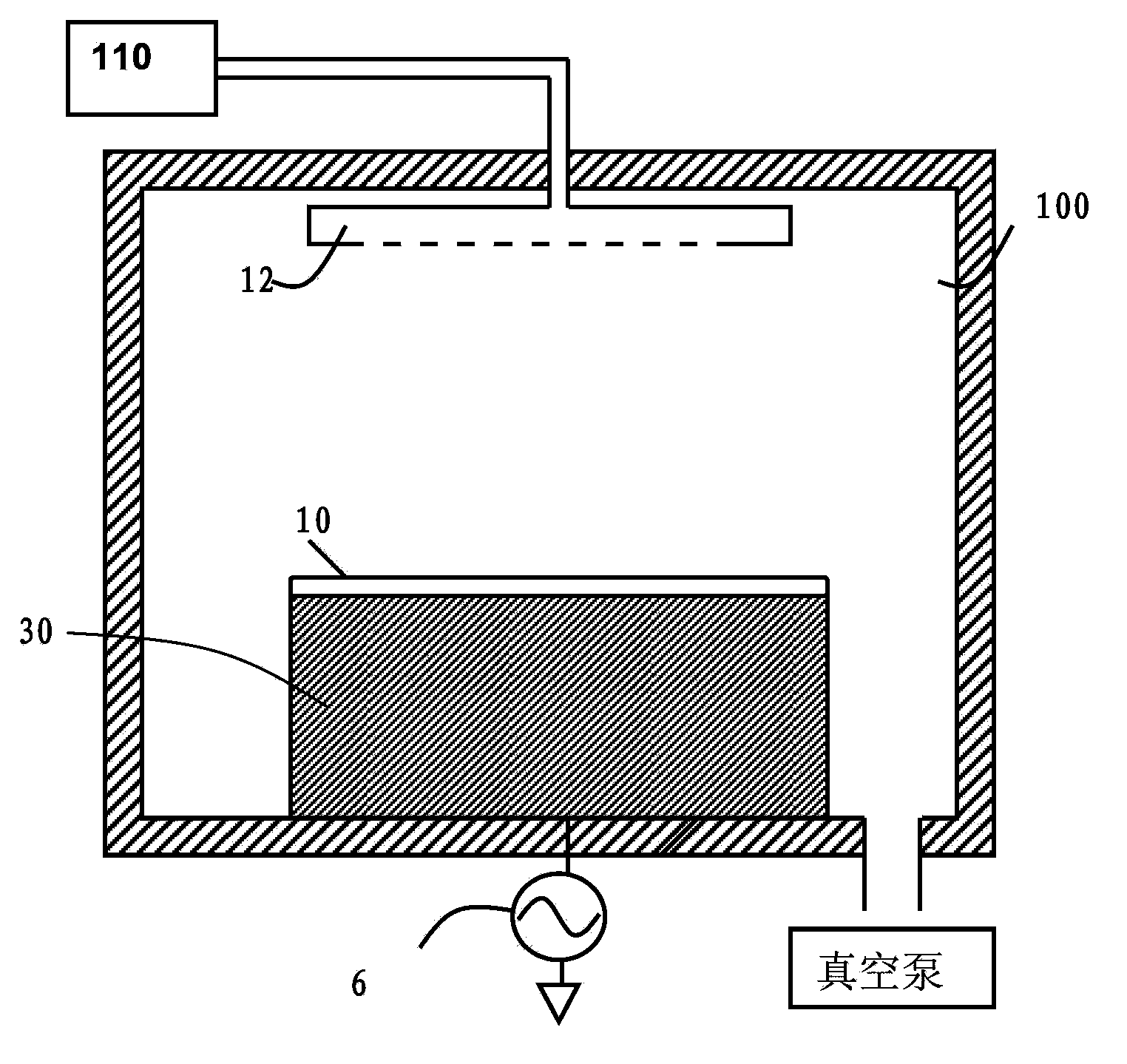

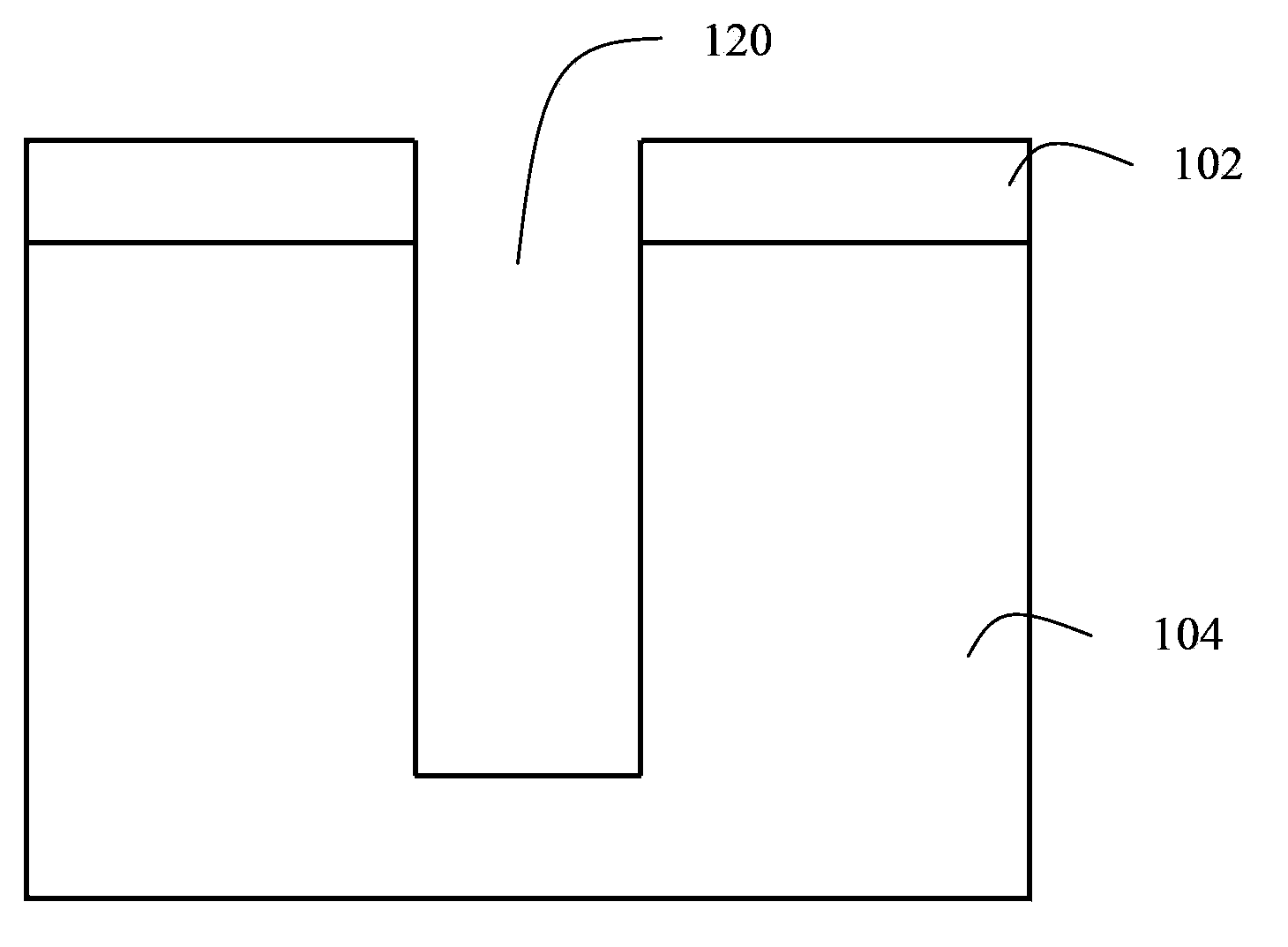

[0022] figure 1 A schematic diagram showing the structure of a plasma etching chamber for etching a substrate to be processed; the substrate to be processed 10 is placed in a plasma etching chamber 100, and the substrate to be processed 10 described in this embodiment is a silicon substrate substrate, figure 2 A schematic structural view of the silicon substrate 102 and its upper mask layer 104 is shown; the plasma etching chamber 100 is provided with a pedestal 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com