Method for preparing high-purity chondroitin sulfate A from rabbit ear cartilage

A chondroitin sulfate, high-purity technology, applied in the field of preparation of high-purity chondroitin sulfate, can solve the problems of chondroitin sulfate application limitations, difficult to obtain raw materials, preparation of chondroitin sulfate, etc., to make up for insufficient market supply, low cost, Product safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

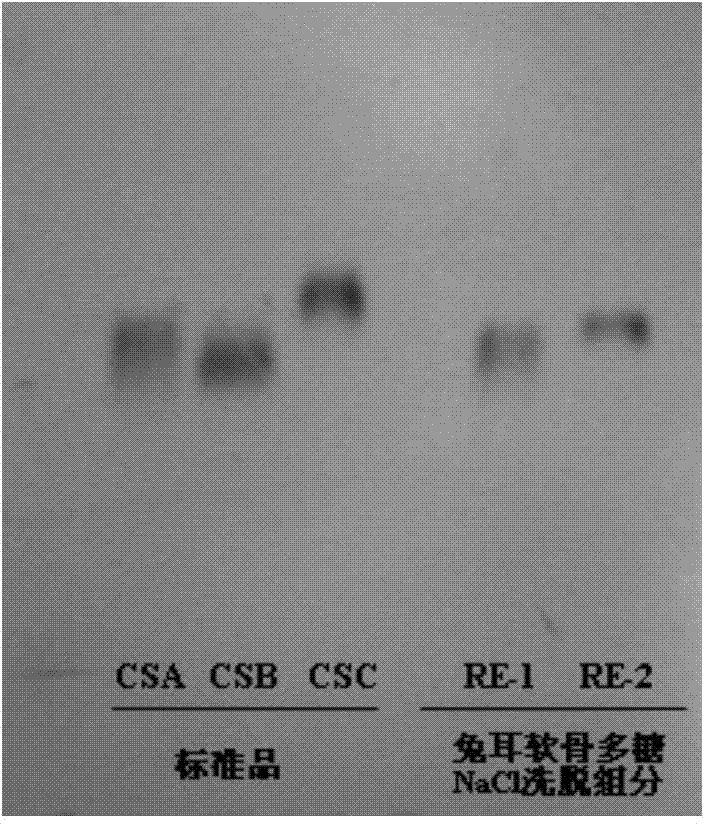

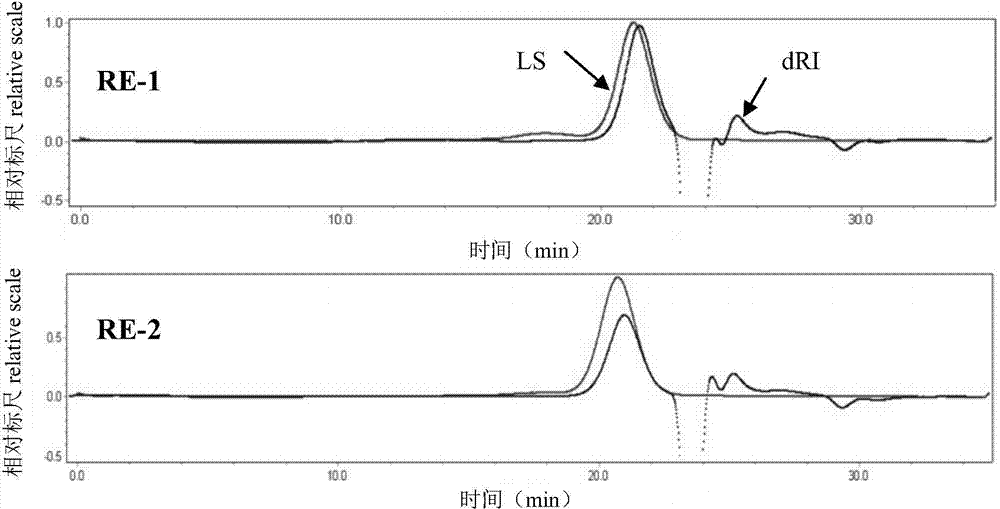

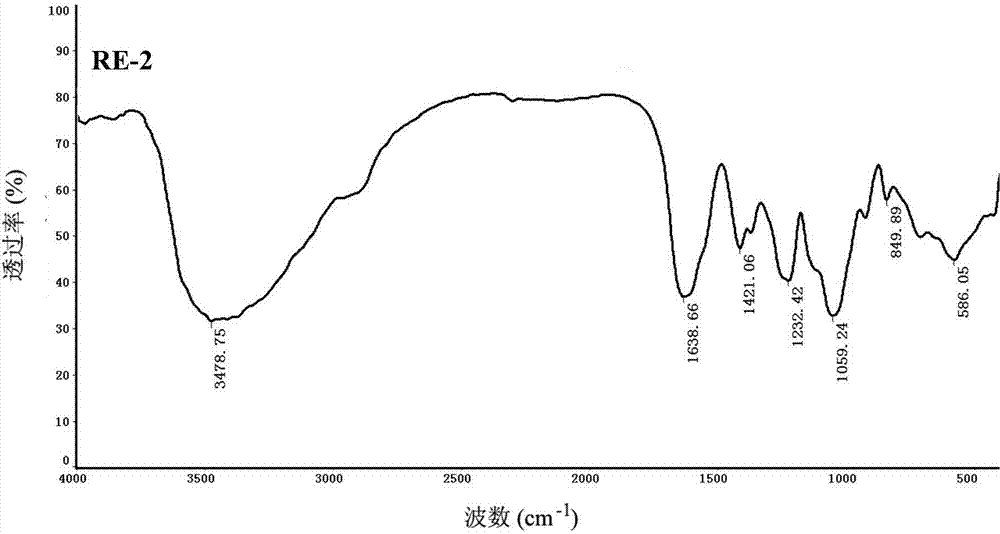

[0028] The preparation method of the high-purity rabbit ear cartilage chondroitin sulfate A provided by the present invention comprises the following steps:

[0029] (1) Degreasing: After the death of the rabbit, the fresh rabbit ears are peeled and fleshed to obtain the rabbit ear cartilage, soaked in an organic solvent, stirred intermittently, taken out and dried, and pulverized to obtain defatted cartilage powder.

[0030] (2) Enzymolysis: Soak defatted cartilage powder in Tris-HCl buffer solution and boil to cool down to 37°C, add trypsin, stir at 37°C for enzymolysis, then boil to inactivate the enzyme.

[0031] (3) Ethanol precipitation: Centrifuge the enzymatic hydrolysis solution obtained in (2), add ethanol to the supernatant to precipitate, take the precipitate after centrifugation, add distilled water to redissolve, then dialyze against distilled water, and obtain the crude chondroitin product after the dialyzed liquid is concentrated and dried under reduced pressure...

Embodiment 1

[0037] Take 3 pairs of fresh rabbit ears, peel and remove the flesh to obtain 35g of rabbit ear cartilage, add 350mL of acetone to soak, stir intermittently for 4h (every 1h, stir for 10 minutes), discard the acetone soaking solution, add 350mL of chloroform / methanol (chloroform and Methanol (volume ratio 4:1) was soaked for 4 hours, the organic solvent was removed, dried and pulverized, and dried to obtain 10.1 g of defatted cartilage powder. Soak defatted cartilage powder in 200mL, 0.1mol / L, Tris-HCl buffer solution with pH=8.0, boil for 2h, cool down to 37°C, add 1.5g trypsin, stir at 37°C for 22h, boil at 100°C for 5min Enzyme inactivation. Centrifuge the enzymatic solution, take the supernatant and add 600mL of absolute ethanol, centrifuge to collect the precipitate, add distilled water to redissolve the precipitate, use a dialysis bag with a cut-off molecular weight of 3500Da for dialysis desalination, concentrate the liquid in the dialysis bag under reduced pressure, and ...

Embodiment 2

[0039] Take 5 pairs of fresh rabbit ears, peel and remove the flesh to obtain 57g of rabbit ear cartilage, add 850mL of acetone to soak, stir intermittently for 8h (every 1h, stir for 5 minutes), remove the acetone, dry and pulverize to obtain 19.4g of defatted cartilage powder. Soak defatted cartilage powder in 390mL, 0.1mol / L, pH=8.0, Tris-HCl buffer solution and boil for 3 hours, then add 5.0g trypsin after cooling down to 37°C, stir at 37°C for 21h, boil at 100°C for 5min to make the enzyme Inactivate. Centrifuge the enzymatic solution, take the supernatant and add 780mL of ethanol with a concentration of 95wt%, centrifuge to collect the precipitate, add distilled water to redissolve the precipitate, and dialyze with a dialysis bag with a cut-off molecular weight of 7000Da until the conductivity of the liquid outside the dialysis bag does not change, and the inside of the dialysis bag The solution was concentrated under reduced pressure and dried to obtain 2.37 g of crude ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com