Method for preparing spherical carbon heavy metal adsorbent

A technology of adsorbent and spherical carbon, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the impact of product adsorption performance, difficult control of reaction conditions, unfavorable commercial production, etc. problems, to achieve the effect of increasing market application prospects and economic benefits, low production costs, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

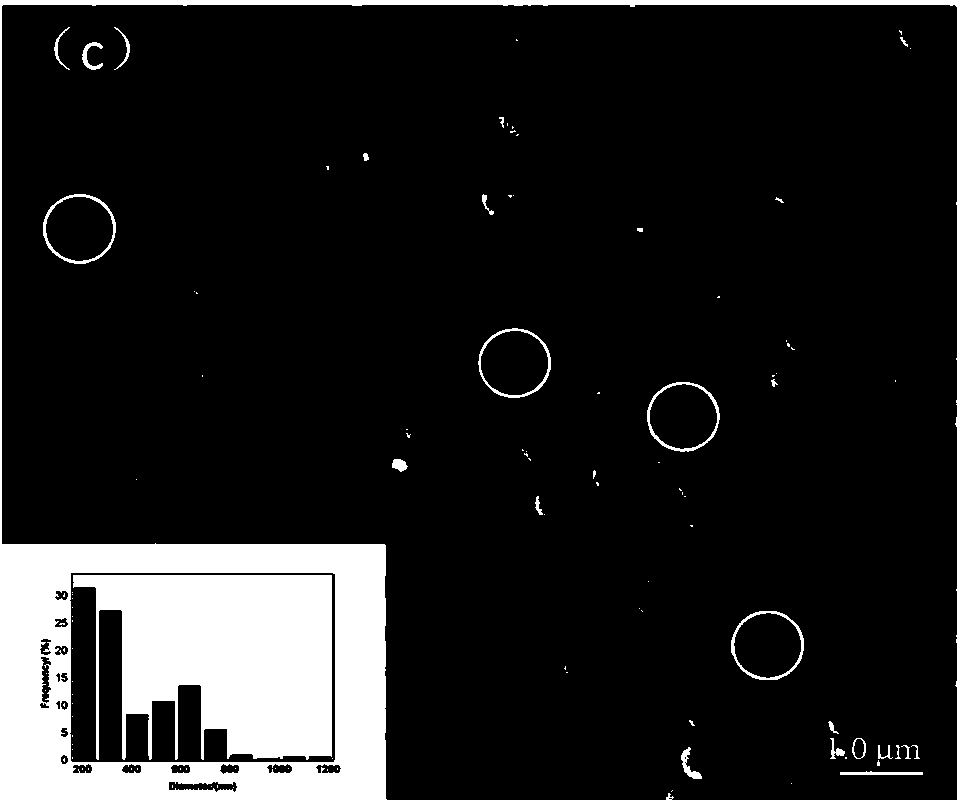

[0026] Prepare the extracted pentosan into an aqueous solution with a concentration of 2%, put it into the reaction kettle with polytetrafluoroethylene, ensure that the volume of the solution and the volume of the kettle are 6:7, and raise the temperature to the target temperature of 210℃ at a heating rate of 10°C / min. Keep the temperature for 12 hours, cool down to room temperature, and centrifuge twice at 6000r / min to obtain a brown solid product. Washed twice with distilled water and absolute ethanol successively, and dried in vacuum for 10 hours to obtain the target product. figure 1 ).

[0027] Prepare Pb with a concentration of 2000mg / L 2+ and Cd 2+Solution, diluted to 100~1000mg / L respectively, take 0.015g of spherical carbon adsorbent in Example 1 and disperse in the Erlenmeyer flask containing 100ml of the above solution whose concentration is V, and vibrate in a constant temperature water bath at 30°C for 48 hours to reach adsorption equilibrium , use a membrane w...

Embodiment 2

[0029] The extracted pentosan was formulated into an aqueous solution with a concentration of 8%, and put into a polytetrafluoroethylene in a reaction kettle to ensure that the volume of the solution and the volume of the kettle were 9:10, and the temperature was raised to the target temperature of 250°C at a heating rate of 10°C / min. Keep the temperature for 9 hours, cool down to room temperature, and centrifuge twice at 10,000 r / min to obtain a brown solid product. Wash with distilled water and absolute ethanol three times successively, and vacuum-dry for 10 hours to obtain the target product, the surface contains 36.5 carboxyl functional groups, and the particle size distribution is 200-1200nm.

[0030] Prepare 2000mg / L of Pb 2+ and Cd 2+ Solution, respectively diluted to 100 ~ 1000mg / L, take example 2 carbon ball 0.015g and disperse in the Erlenmeyer flask containing 100ml of the above solution with a concentration of V, shake in a constant temperature water bath at 30 de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com