A method for online roll coating of anti-ultraviolet coated glass

An anti-ultraviolet, coated glass technology, applied in the field of glass coating, can solve the problems of uneven film layer, poor film forming effect, increased cost, etc., and achieve the effect of good film bonding force, easy maintenance, and reduced energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

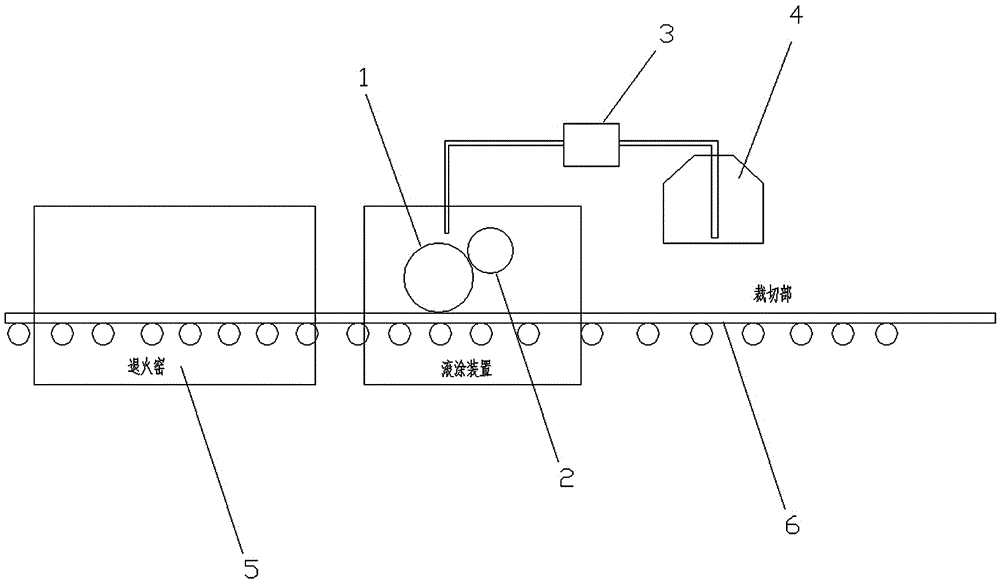

Image

Examples

Embodiment 1

[0019] In the 600t / d float glass production line, the width of the glass plate is 4200mm, the thickness of the glass plate is 5mm, the speed of the glass plate is 9m / min, and the temperature of the glass plate surface at the exit of the return kiln is 50°C.

[0020] The coating solution is composed of nano-silicon dioxide with a mass concentration of 0.1, 0.5% nano-titanium dioxide, 0.1% nano-iron oxide, and the rest is ethanol. The configuration process of the coating solution mixes various reactive substances together, and there is no order of addition , Stir evenly at room temperature, and the coating solution needs to be heated to the same temperature as the glass substrate to be coated.

[0021] The length of the coated rubber roller is consistent with the width of the glass plate, and the contact depth between the bottom end of the coated rubber roller and the upper surface of the glass is 0.1mm (that is, the bottom end of the rubber roller contacts the glass surface and ...

Embodiment 2

[0023] In the 450t / d calendered glass production line, the width of the glass plate is 3300mm, the thickness of the glass plate is 5mm, the speed of the glass plate is 9m / min, the temperature of the glass plate surface at the outlet of the return kiln is 80°C, and the length of the coating roller is consistent with the width of the glass plate. The contact depth between the bottom end of the coating roller and the upper surface of the glass is 0.5mm. The coating solution contains 1.5% nano-silicon dioxide, 2% nano-titanium dioxide, 0.5% nano-iron oxide, and the rest is isopropanol. The film layer is at room temperature Cured, the thickness is about 100nm, and it blocks about 85% of ultraviolet rays measured according to the ISO9050 standard.

Embodiment 3

[0025] On a 300t / d flat-drawn glass production line, the width of the glass plate is 3300mm, the thickness of the glass plate is 5mm, the speed of the glass plate is 9m / min, the temperature of the glass plate surface at the exit of the return kiln is 100°C, and the length of the coating roller is consistent with the width of the glass plate , the contact depth between the bottom end of the coated rubber roller and the upper surface of the glass is 1mm, the coating solution contains 3% nano-silicon dioxide, 5% nano-titanium dioxide, 1% nano-iron oxide, and the rest is acetone, and the film layer is cured at room temperature. The thickness is about 150nm, and it blocks about 90% of ultraviolet rays measured according to the ISO9050 standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com