Semi-synthesis method for high-purity and high-stability gastrodin

A high-stability, gastrodin technology, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problem that acetyl gastrodin cannot be directly separated, the stability of acetyl gastrodin is not good, and the cost of production management is increased. and other problems, to achieve the effect of low price, improved yield and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

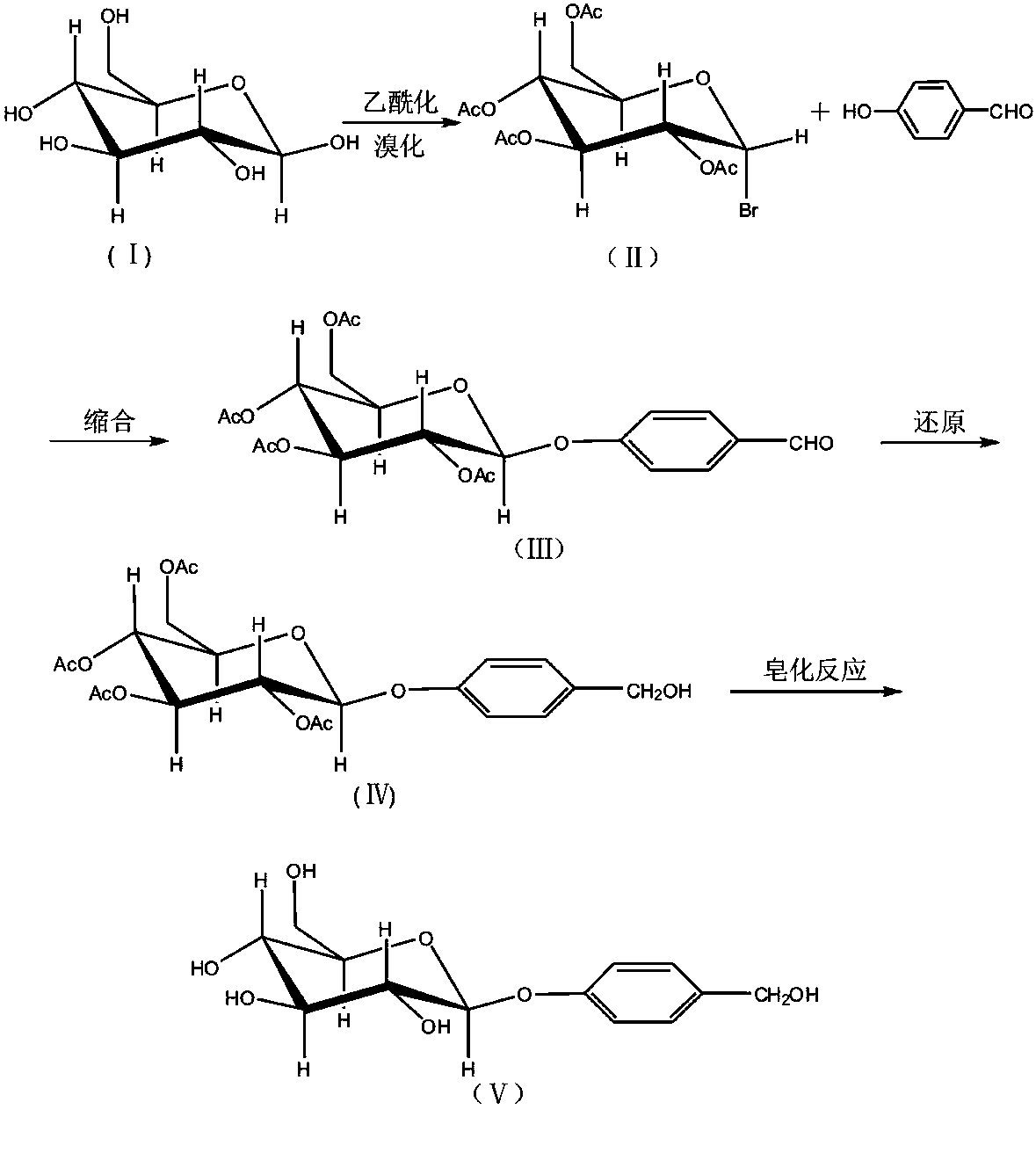

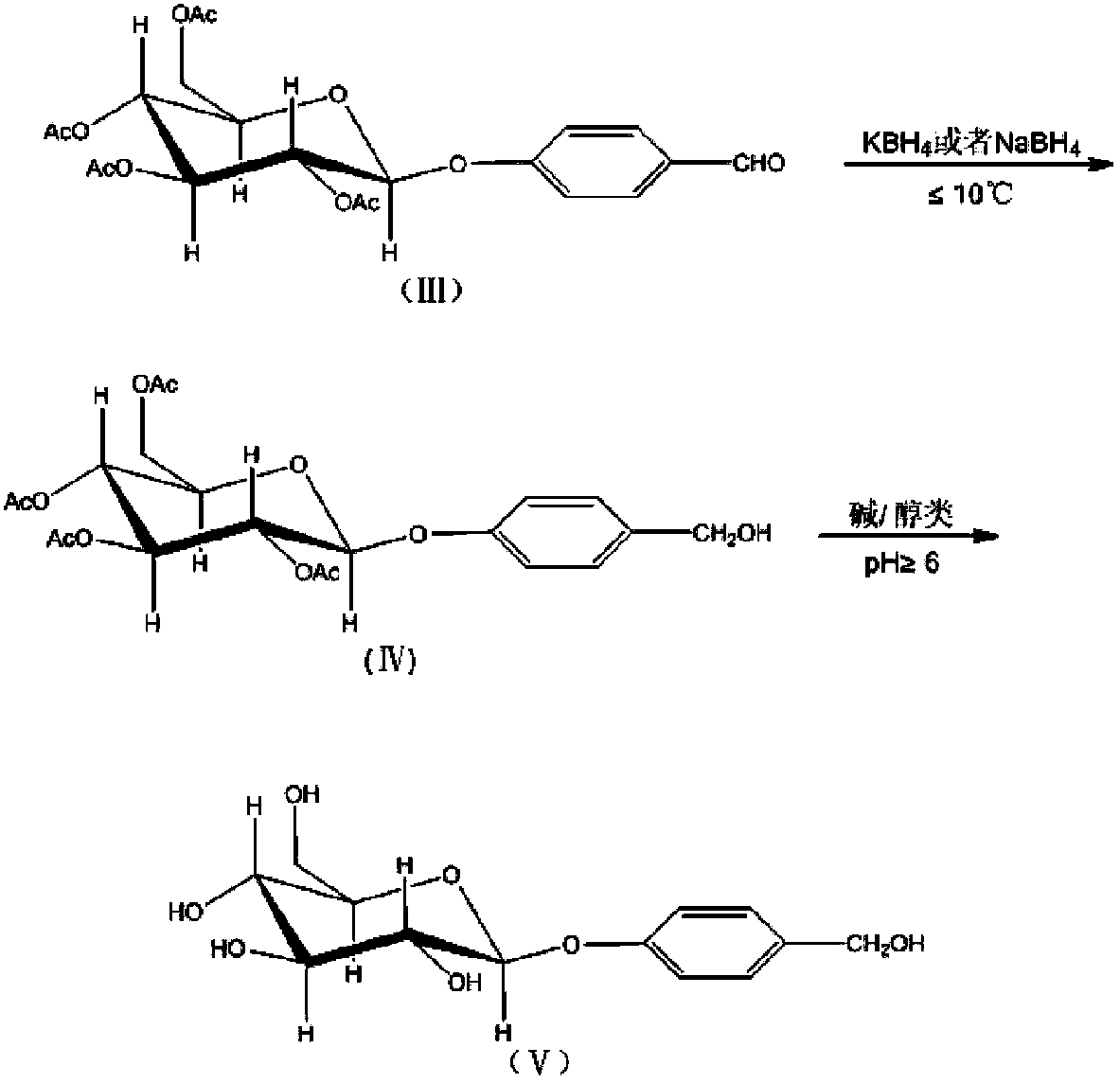

[0023] Such as figure 2 As shown, the semi-synthetic method of high-purity and high-stability gastrodin described in the present invention comprises the steps of preparing acetylgastrodin, crude gastrodin, refining gastrodin, and recovering crude gastrodin, specifically including:

[0024] A. Preparation of acetylgastrodin: use tetraacetyl as raw material, add alcohol solvent or alcohol ester mixed solvent with a volume-to-weight ratio of 2 to 50 times, control the system temperature ≤ 10°C, add a reducing agent for reduction reaction, stir until the reaction liquid Adding the chromogenic agent does not show red, that is, stop the reaction; add acid to adjust the pH to 2~8, concentrate the reaction solution to 1.5~6 times the volume-to-weight ratio of tetraacetyl, and then add 0~12 times the volume ratio to the concentrated solution The water is filtered and dried to obtain acetylgastrodin, and the filtrate is reclaimed as mother liquor a for recycling;

[0025] B. Crude gas...

Embodiment approach

[0029] A. Preparation of acetylgastrodin: use tetraacetyl as raw material, add alcohol solvent or alcohol ester mixed solvent with a volume-to-weight ratio of 3 to 25 times, control the system temperature at 0°C to 5°C, add a reducing agent for reduction reaction, and stir until Adding the color developer dropwise to the reaction liquid does not show red color, that is, stop the reaction; add acid to adjust the pH to 6~7, concentrate the reaction liquid to 1.5~6 times the volume-to-weight ratio of tetraacetyl, and then add a volume ratio of 4~6 to the concentrated solution. 6 times of water, filtered and dried to obtain acetylgastrodin with a yield of 92-98%; reclaim the filtrate as mother liquor a for recycling;

[0030] B. Crude gastrodin: Add methanol, ethanol or propanol with a volume-to-weight ratio of 2 to 10 times the volume to weight of the prepared acetyl gastrodin, add alkali to adjust and maintain the system pH ≥ 6, and stop the reaction after 0.5 to 3 hours of reflu...

Embodiment 1

[0044] Take 1 kg of tetraacetyl, add 5 L of methanol-methyl formate mixed solvent with a volume ratio of 3:1 and mix evenly; control the temperature of the system at 6°C, add potassium borohydride for reduction reaction, and continue stirring; after 28 minutes of reaction, take a sample and add dropwise color agent, the reaction stops when there is no color development (if the color is red, continue to add potassium borohydride for reaction); after the reaction is stopped, add perchloric acid, adjust the pH to 6, concentrate the volume of the reaction solution to 5L, and add to the concentrated solution Add 30L of water, stir evenly, filter and dry to obtain 0.96kg of acetylgastrodin, with a yield of 95.58%; the filtrate is mother liquor a, which is recovered for subsequent use;

[0045] Add 3L of methanol to 0.96kg of acetylgastrodin, feed ammonia gas to adjust and maintain the pH of the system to 7, stop the reaction after 2 hours of reflux reaction, concentrate to 1.5L, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com