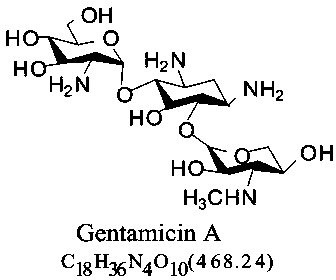

Engineering bacterium producing gentamicin A and application thereof

A gentamicin and engineering bacteria technology, applied in bacteria, recombinant DNA technology, introduction of foreign genetic material using vectors, etc., can solve the problems of slow progress in the application and development of Micromonospora, inability to achieve industrialization, and hindering antiprotozoa. , to achieve the effect of no chromatographic separation pollution, convenient extraction, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

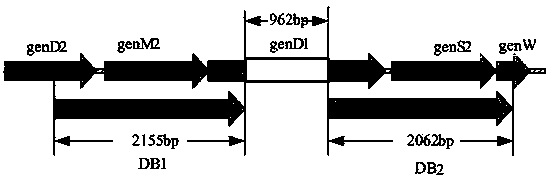

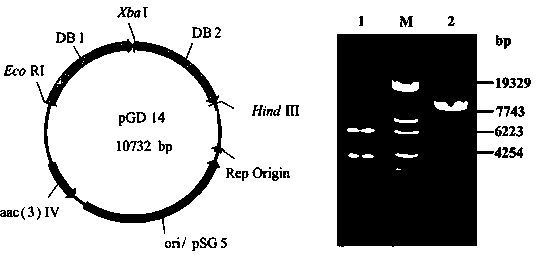

[0036] 1. Construction of recombinant plasmid pGD14

[0037] According to the gentamicin biosynthesis gene cluster of Micromonas magenta that we constructed in 2012 (GenBank accession No.: JQ975418, 44181bp) and the gentamicin biosynthesis gene cluster of Micromonas aculeatus published by Piepersberg et al. (GenBank Accession Number AJ628149), in Gene genD1 The upstream and downstream design of the exchange arm, using an in-frame knockout scheme (attached figure 1 ). Upstream Swap Arm Primer P1 / P2 (P1: 5’- GAATTC CTGTGCCGCTGGATGCTC-3', EcoRI ; P2: 5'- TCTAGA GATACGTTCCGGCTCGTCGC-3', wxya ); downstream exchange arm primer P3 / P4 (P3: 5'- TCTAGA AAGGGCAACCGGATGGAG-3', wxya ); P4: 5’- AAGCTT CGGGACGGTATTCGATCC-3', Hind III ). Using the genome of the starting strain Micromonospora crimson G1008 (see patent: 201110331534.9) as a template, with the help of PCR technology, using primers P1 / P2 to amplify the gene Gen D The upstream sequence of the homolog...

Embodiment 2

[0043] Embodiment 2: the preparation of the metabolite Gentamicin A of Micromonospora crimson rubrum GKD1989

[0044] provided by the invention genD1 Knockout engineered bacteria: Micromonospora magenta GKD1989 can be directly used to produce gentamicin A.

[0045] 1. Fermentation and Culture of Micromonospora Crimson GKD1989 Strain

[0046] Seed medium: glucose 0.1%, corn starch 1.0%, corn flour 1.5%, peptone 0.2%, soybean meal 1.0%, KNO 3 0.05%, CaCO 3 0.5%, pH7.0.

[0047] Fermentation medium: corn starch 6.0%, corn flour 1.0%, peptone 0.4%, soybean cake powder 2.0%, KNO 3 0.01%, (NH 4 ) 2 SO 4 0.1%, CaCO 3 0.5%, amylase 0.025%, pH7.5.

[0048] Micromonospora magenta GKD1989 obtained in step 3 in Example 1 was fermented. Before fermentation, isolate the single colony with rich sporulation by dilution plate method and transfer it to the slant medium, culture at 37°C for 10 days, excavate the block and inoculate it into the seed medium (50mL / 250mL Erlenmeyer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com