Dual-pulse gold plating process

A double-pulse, process technology, applied in the field of gold plating, can solve the problems of shortened service life of the gold plating solution, stability of the plating solution, inconvenient operation and management, etc., and achieve low porosity, bright bonding force, and uniform distribution of coating thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] When using the following cyanide-free gold plating solution for electroplating, select the nickel electrode as the cathode and the platinum sheet as the anode.

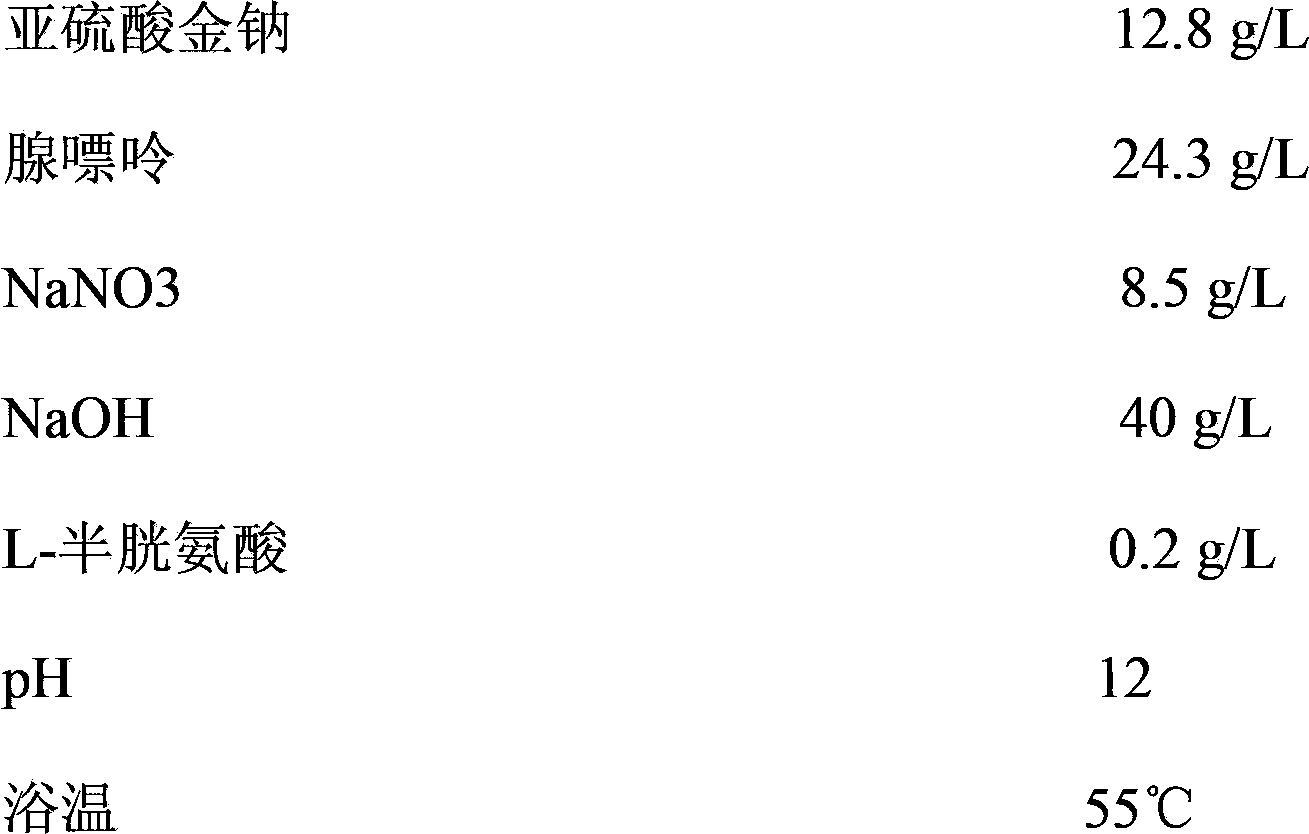

[0030] The composition of the gold plating solution is as follows:

[0031]

[0032] The parameters of double pulse electroplating are: the positive pulse frequency is 700Hz, the time is 50ms, the duty ratio is 10%, and the current density is 0.3A / dm 2 ; Negative pulse frequency is 700Hz, time is 20ms, duty ratio is 5%, current density is 0.03A / dm 2 .

[0033] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free gold plating electroplating solution. As a result, the nickel electrodes were plated with gold.

Embodiment 2

[0035] Gold plating with the method same as embodiment 1, change the composition of gold plating solution, pH, current density, bath temperature, as a result nickel electrode has been plated with gold.

[0036]

[0037] The parameters of double pulse electroplating are: the positive pulse frequency is 1000Hz, the time is 100ms, the duty ratio is 20%, and the current density is 0.4A / dm 2 ; Negative pulse frequency is 1000Hz, time is 80ms, duty ratio is 10%, current density is 0.04A / dm 2 .

Embodiment 3

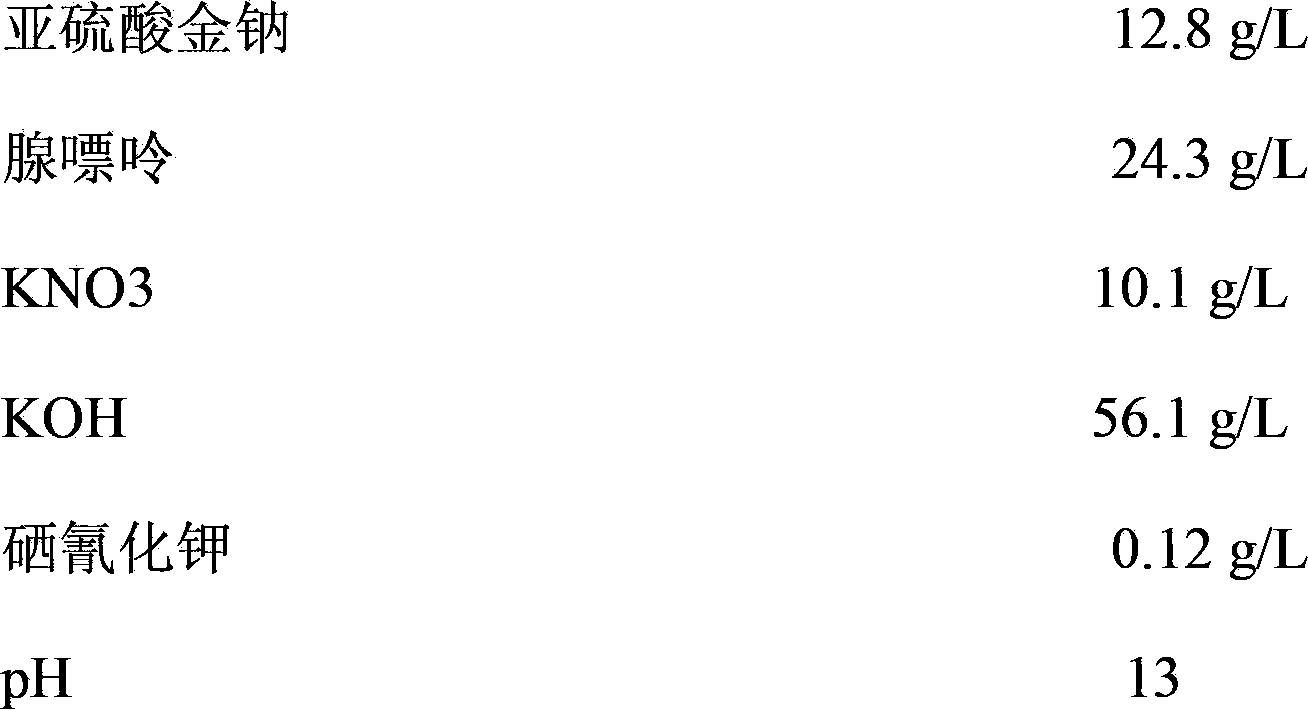

[0039] Gold plating with the method same as embodiment 1, change the composition of gold plating solution, pH, current density, bath temperature, as a result nickel electrode has been plated with gold.

[0040]

[0041]

[0042] The parameters of double pulse electroplating are: the positive pulse frequency is 700Hz, the time is 50ms, the duty ratio is 10%, and the current density is 0.3A / dm 2 ; Negative pulse frequency is 1000Hz, time is 80ms, duty ratio is 10%, current density is 0.04A / dm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com