Preparation method of metal anti-corrosion coating

A metal anti-corrosion and coating technology, which is applied in the direction of anti-corrosion coatings, metal layered products, coatings, etc., can solve problems such as metal anti-corrosion coatings that have not yet been seen, and achieve excellent anti-corrosion performance, good society, and uniform anti-corrosion coatings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

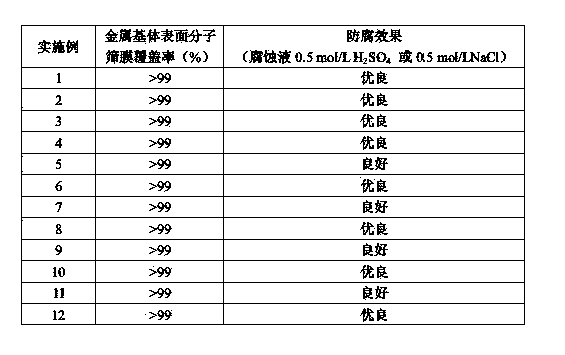

Examples

Embodiment 1

[0022] The preparation method of metal anticorrosion coating comprises the following steps:

[0023] (1) Preparation of synthetic liquid gel, said synthetic liquid gel is a mixture of tetrapropylammonium hydroxide, ethyl orthosilicate and water, in terms of molar ratio, tetrapropylammonium hydroxide: ethyl orthosilicate Ester: water = 0.36: 1: 20; after the synthetic liquid gel is prepared, it is aged at room temperature for 24 hours;

[0024] (2) Dilute the synthetic liquid gel prepared in step (1) with a diluent, the diluent is methanol, and dilute with equal volume. After dilution, the synthetic liquid gel is evenly coated on the surface of the metal substrate, and after drying, a uniform gel with a flat surface is obtained. The metal substrate of the adhesive layer; the metal substrate is aluminum alloy, the model is 1060;

[0025] (3) Add the reaction medium in the reaction kettle, the reaction medium is 0.5g water; put the metal substrate with a flat and uniform gel lay...

Embodiment 2

[0027] The preparation method of the metal anti-corrosion coating provided in this embodiment is the same as in Example 1, and the formula of the synthetic liquid gel in the adjustment step (1) is, in terms of molar ratio, tetrapropylammonium hydroxide: tetraethyl orthosilicate : water = 0.30: 1: 14; adjust the diluent to ethanol solution and dilute with equal volume.

Embodiment 3

[0029] This example is the same as the preparation method of the metal anti-corrosion coating provided in Example 1, and the reaction medium in the reaction kettle in the step (3) is adjusted to 0.5 g of ethylenediamine solution with a mass fraction of 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com