Method for degrading lignin in seawater

A technology of lignin and seawater, applied in the energy field, can solve the problems of reduced utilization value, high raw material cost and separation cost, damage to benzene ring structure, etc., and achieves the effects of low cost, safe operation and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

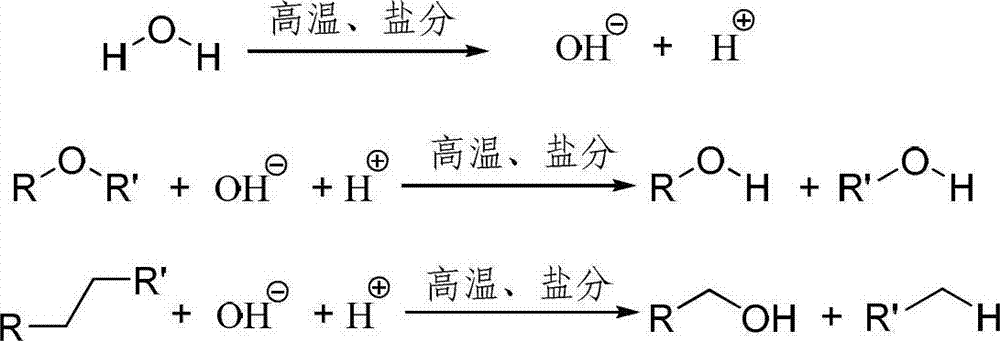

Method used

Image

Examples

Embodiment 1

[0019] Mix 10g of Alcell lignin and 100ml of natural seawater and transfer to the autoclave (Parr4740). After replacing the air with nitrogen 3-5 times, heat to 260°C. After 8 hours of reaction, the stirring was stopped, the temperature was lowered to room temperature, and 40 mL of chloroform was added in 3 times to extract the reaction solutions and then combined, and the organic liquid mixture was distilled to obtain 9.0 g, which accounted for 90% of the charged amount. The products were analyzed by chromatography-mass spectrometry. The main products were coniferyl alcohol (40%), coumarol (35%), vanillin (12%), syringyl derivatives (8%), and other products 5% (including Dimers and trimers).

Embodiment 2

[0021] Mix 3g of Alcell lignin with 10ml of sea water and transfer to a pressure-resistant airtight container (Swagelokminitube). After replacing the air with nitrogen 3-5 times, heat to 350°C. After 20 hours of reaction, the stirring was stopped, the temperature was lowered to room temperature, and 40 mL of petroleum ether was added in 3 times to extract the reaction solution and then combined, and the organic liquid mixture was obtained by distillation, which was 2.5 g, which accounted for 83% of the charge. The products were analyzed by chromatography-mass spectrometry. The main products were coniferyl alcohol (38%), coumarol (36%), vanillin (15%), syringyl derivatives (6%), and other products 5% (including Dimers and trimers). From the experimental results, using the same raw material, changing the reaction conditions has little effect on product distribution, and the proportion of product units is determined by the properties of lignin itself.

Embodiment 3

[0023] Mix 6g of Alcell lignin and 10ml of sea water and transfer to a pressure-resistant airtight container (Swagelokminitube). After replacing the air with nitrogen 3-5 times, heat to 350°C. After reacting for 20 hours, the stirring was stopped, the temperature was lowered to room temperature, and 40 mL of petroleum ether was added in 3 times to extract the reaction solution and then combined, and the organic liquid mixture was distilled to obtain 3.2 g, accounting for 53% of the charge. The products were analyzed by chromatography-mass spectrometry. The main products were coniferyl alcohol (34%), coumarol (35%), vanillin (17%), syringyl derivatives (5%), and other products 9% (including Dimers and trimers). From the experimental results, increasing the amount of lignin, the yield of organic liquid products was significantly reduced, and the amount of polymers also increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com