Synthetic method of high-purity solid sodium dimethyl dithiocarbamate

A synthesis method and a technology of sodium formate, applied in the field of synthesis of high-purity solid sodium formate, can solve the problems of high loss of carbon disulfide and dimethylamine, incomplete reaction of dimethylamine, low content, etc., and reduce the overall product cost and avoid Poor operating environment, the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

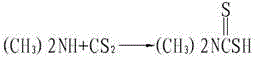

Method used

Image

Examples

Embodiment 1

[0036] Select a synthetic kettle with a volume of 2000L, and prepare solid sodium hydroxide, demineralized water, carbon disulfide and dimethylamine in a weight ratio of 525:525:1060:635.

[0037] 1. Add 525Kg of demineralized water into the synthesis kettle, start the agitator to stir, add 525Kg of solid sodium hydroxide within 30 minutes, and feed the cooling medium frozen brine into the jacket of the synthesis kettle. The temperature is generally 3~10℃, and control the The temperature of the inner material is 20~25°C, so that the solid sodium hydroxide is completely dissolved, and the mass fraction of the completely dissolved sodium hydroxide is slightly lower than 50%, generally 49.5%;

[0038] 2. Press 1060Kg carbon disulfide into the carbon disulfide high level tank from the storage tank with nitrogen;

[0039] 3. Pass 635Kg of gas dimethylamine from the bottom of the synthesis kettle, and add carbon disulfide from the upper part of the synthesis kettle at the same time,...

Embodiment 2

[0049] Select a synthetic kettle with a volume of 2000L, and prepare solid sodium hydroxide, demineralized water, carbon disulfide and dimethylamine in a weight ratio of 475:475:970:578.

[0050] 1. Add 475Kg of demineralized water into the synthesis kettle, start the stirrer to stir, add 475Kg of solid sodium hydroxide within 25 minutes, feed cooling medium into the jacket of the synthesis kettle, control the temperature of the material in the kettle to 10~20℃, and make the solid Sodium hydroxide is completely dissolved;

[0051] 2. Press 970Kg of carbon disulfide into the carbon disulfide high level tank from the storage tank with nitrogen;

[0052] 3. Pass 578Kg of gas dimethylamine from the bottom of the synthesis kettle, and add carbon disulfide from the upper part of the synthesis kettle at the same time, adjust the stirring speed of the stirrer to 63rpm, and control the reaction temperature to 25~30°C;

[0053] 4. Add carbon disulfide and gaseous dimethylamine into the...

Embodiment 3

[0062] Select a synthetic kettle with a volume of 3000L, and prepare solid sodium hydroxide, demineralized water, carbon disulfide and dimethylamine in a weight ratio of 750:775:1530:900.

[0063] 1. Add 750Kg of demineralized water into the synthesis kettle, start the stirrer to stir, add 775Kg of solid sodium hydroxide within 40 minutes, feed cooling medium into the jacket of the synthesis kettle, control the temperature of the material in the kettle to 20~25℃, and make the solid Sodium hydroxide is completely dissolved;

[0064] 2. Press 1530Kg carbon disulfide into the carbon disulfide high level tank from the storage tank with nitrogen;

[0065] 3. Pass 900Kg of gas dimethylamine from the bottom of the synthesis kettle, and add carbon disulfide from the upper part of the synthesis kettle at the same time, adjust the stirring speed of the stirrer to 80rpm, and control the reaction temperature to 25~35°C;

[0066] 4. Carbon disulfide and gaseous dimethylamine are added to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com