Organic electroluminescent device and preparation method thereof

An electroluminescent device and electroluminescent technology, which are applied in the directions of organic light-emitting devices, organic semiconductor devices, materials of organic semiconductor devices, etc., can solve the problems of difficult process control, unfavorable industrial production, and low HOMO energy level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

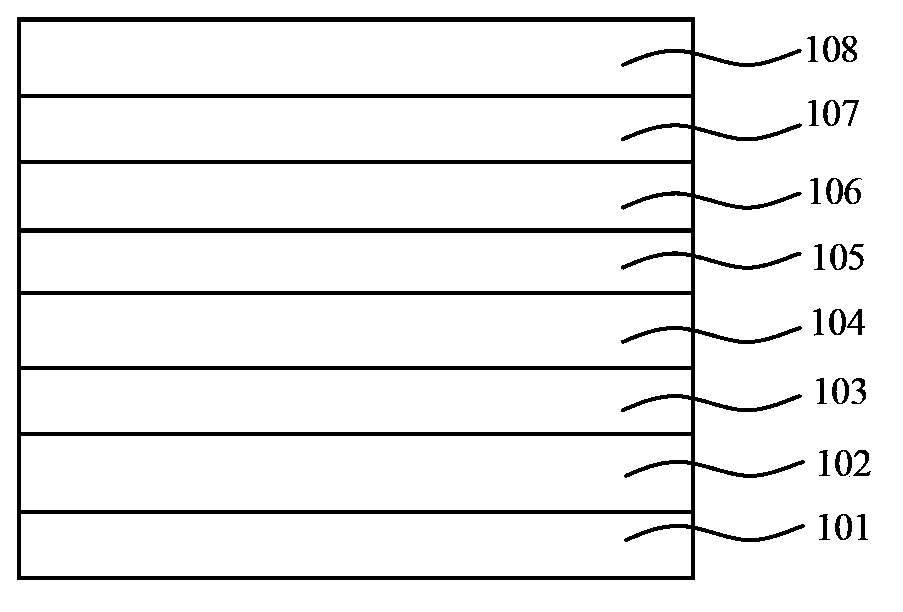

[0075] A method for preparing an organic electroluminescent device, comprising the following steps:

[0076] (1) Conductive anode substrate pretreatment

[0077] Sonicate the ITO substrate with a thickness of 100nm for 15 minutes with detergent and deionized water in order to remove organic pollutants on the glass surface.

[0078] (2) Preparation of hole injection layer, hole transport layer, light emitting layer, hole blocking layer, electron transport layer, electron injection layer

[0079] Place the pretreated ITO substrate in a vacuum chamber (high vacuum coating system, Shenyang Scientific Instrument Development Center Co., Ltd.), and evacuate to 5×10 -3 Pa, with the vapor deposition rate of 1nm / s 2 o 5 Evaporated on the ITO substrate as a hole injection layer with a thickness of 50nm;

[0080] Evaporate TAPC on the hole injection layer as a hole transport layer at an evaporation rate of 1 nm / s, with a thickness of 40 nm;

[0081] 8-hydroxyquinoline aluminum (Alq ...

Embodiment 2

[0090] A method for preparing an organic electroluminescent device, comprising the following steps:

[0091] (1) Conductive anode substrate pretreatment

[0092] The AZO substrate with a thickness of 80nm was ultrasonicated for 15 minutes with detergent and deionized water in order to remove organic pollutants on the glass surface.

[0093] (2) Preparation of hole injection layer, hole transport layer, light emitting layer, hole blocking layer, electron transport layer, electron injection layer

[0094] Place the pretreated AZO substrate in a vacuum chamber (high vacuum coating system, Shenyang Scientific Instrument Development Center Co., Ltd.), and evacuate to 2×10 -4 Pa, WO was deposited at a deposition rate of 10nm / s 3 Evaporated on the AZO substrate as a hole injection layer with a thickness of 80nm;

[0095] N,N'-diphenyl-N,N'-bis(1-naphthyl)-1,1'-biphenyl-4,4'-diamine (NPB) was deposited at a deposition rate of 0.1nm / s Evaporated on the hole injection layer as a hol...

Embodiment 3

[0104] A method for preparing an organic electroluminescent device, comprising the following steps:

[0105] (1) Conductive anode substrate pretreatment

[0106] The IZO substrate with a thickness of 300nm was ultrasonicated for 15 minutes with detergent and deionized water in sequence to remove organic pollutants on the glass surface.

[0107] (2) Preparation of hole injection layer, hole transport layer, light emitting layer, hole blocking layer, electron transport layer, electron injection layer

[0108] Place the pretreated IZO substrate in a vacuum chamber (high vacuum coating system, Shenyang Scientific Instrument Development Center Co., Ltd.), and evacuate to 2.5×10 -3 Pa, MoO was deposited at a deposition rate of 5nm / s 3 Evaporated on the IZO substrate as a hole injection layer with a thickness of 40nm;

[0109] Evaporate TCTA on the hole injection layer as a hole transport layer at an evaporation rate of 0.5nm / s, and its thickness is 45nm;

[0110] Evaporate BCzVB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com