Preparation method of polyvinylidene fluoride porous membrane with diversity charging surface

A polyvinylidene fluoride membrane and polyvinylidene fluoride technology, which is applied in the field of surface modification of separation membranes, can solve the problems of organic pollutant accumulation, reduce separation efficiency and service life, and achieve the effect of good anti-pollution performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

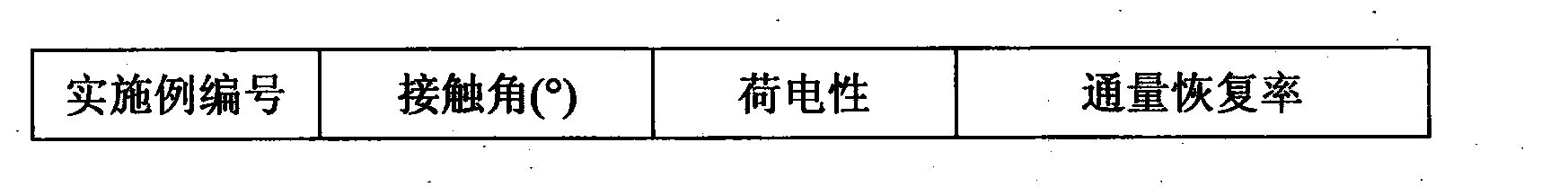

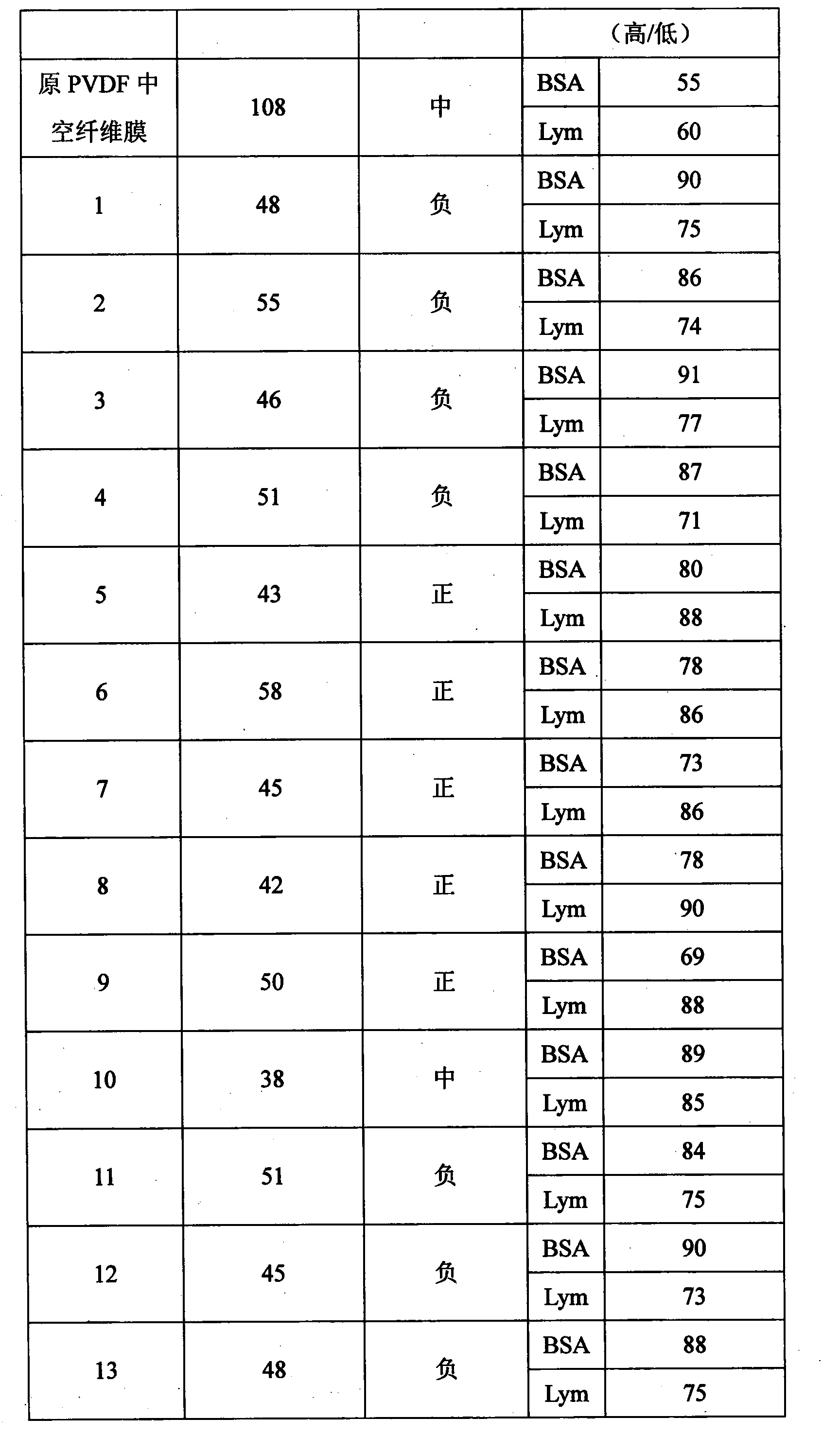

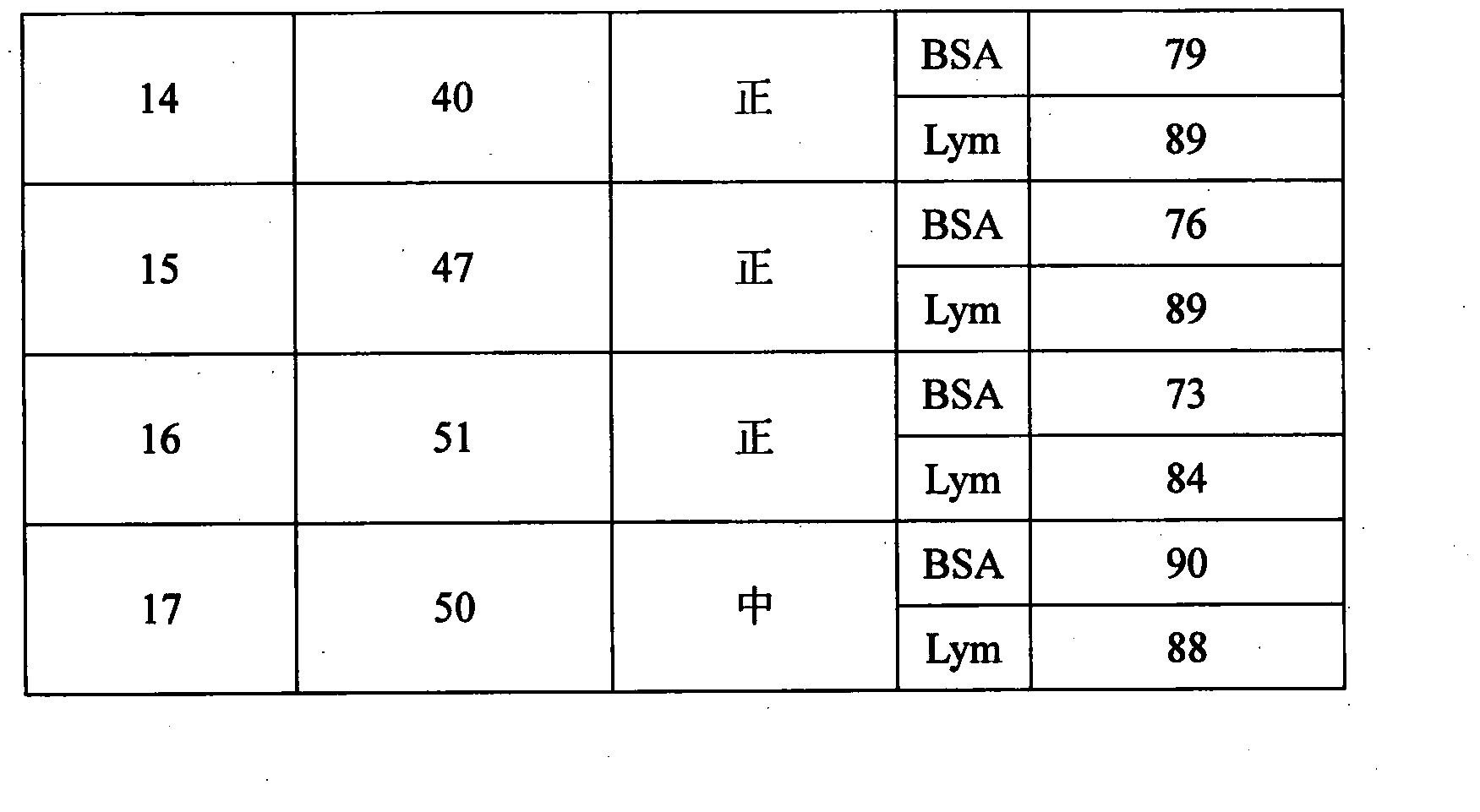

Examples

Embodiment 1

[0029] After a certain length of PVDF hollow fiber membrane is cleaned and dried, it is placed in a low-temperature plasma instrument for pretreatment. The treatment conditions are: the distance between the membrane and the electrode is 5 cm, the discharge gas in the chamber is oxygen, and the discharge power It is 50 watts, the gas pressure is 20 Pa, and the processing time is 60 seconds. The pretreated PVDF membrane was oxidized in air for 10 minutes, then immersed in 50% acrylic acid aqueous solution, and carried out surface graft polymerization reaction under nitrogen protection for 2 hours, and the reaction temperature was 60°C to obtain a PVDF membrane with polyacrylic acid surface modification ; The PVDF membrane with polyacrylic acid surface modification was placed in 1% chitosan solution, 1% sodium alginate solution, 1% chitosan solution, 1% sodium alginate solution for adsorption, each time for 10min, each time Before and after the first adsorption, the modified memb...

Embodiment 2

[0031] After a certain length of PVDF hollow fiber membrane is cleaned and dried, it is placed in a low-temperature plasma instrument for pretreatment. The treatment conditions are that the distance between the membrane and the electrode is 5 cm, the discharge gas introduced into the chamber is oxygen, and the gas pressure is 20 Pa, the discharge power is 150 watts, and the processing time is 30 seconds. The pretreated PVDF membrane was oxidized in the air for 10 minutes, then immersed in 50% acrylic acid aqueous solution, and the surface graft polymerization was carried out under nitrogen protection for 3 hours, and the reaction temperature was 50°C to obtain a polyacrylic acid surface-modified PVDF membrane. , and finally the PVDF membrane with polyacrylic acid surface modification was placed in 1% chitosan solution, 1% polyacrylic acid solution, 1% chitosan solution, and 1% polyacrylic acid solution for adsorption, each time for 150min, each time Before and after adsorption...

Embodiment 3

[0033] After a certain length of PVDF hollow fiber membrane is cleaned and dried, it is placed in a low-temperature plasma instrument for pretreatment. The treatment conditions are that the distance between the membrane and the electrode is 5 cm, the discharge gas introduced into the chamber is oxygen, and the gas pressure is 30 Pa, the discharge power is 60 watts, and the processing time is 180 seconds. The pretreated PVDF membrane was oxidized in the air for 10 minutes, then immersed in 50% acrylic acid aqueous solution, and the surface graft polymerization was carried out under nitrogen protection for 0.5 hours, and the reaction temperature was 8°C to obtain a polyacrylic acid surface-modified PVDF membrane. , and then the polyacrylic acid surface-modified PVDF membrane was placed in 1% chitosan solution, 1% polyphosphate solution, 1% chitosan solution, and 1% polyphosphate solution for adsorption. 90min, before and after each adsorption, the modified membrane should be ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com