Three-dimensional graphene-based combined electrode with MnO2 and Au nanoparticle-coating surface, and preparation method and applications thereof

A graphene-based, nano-particle technology, applied in the field of composite electrodes for lithium-air batteries, can solve the problems of no three-dimensional graphene-based composite electrode materials, etc., to achieve improved electrochemical performance, high cycle stability, and reduced overpotential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

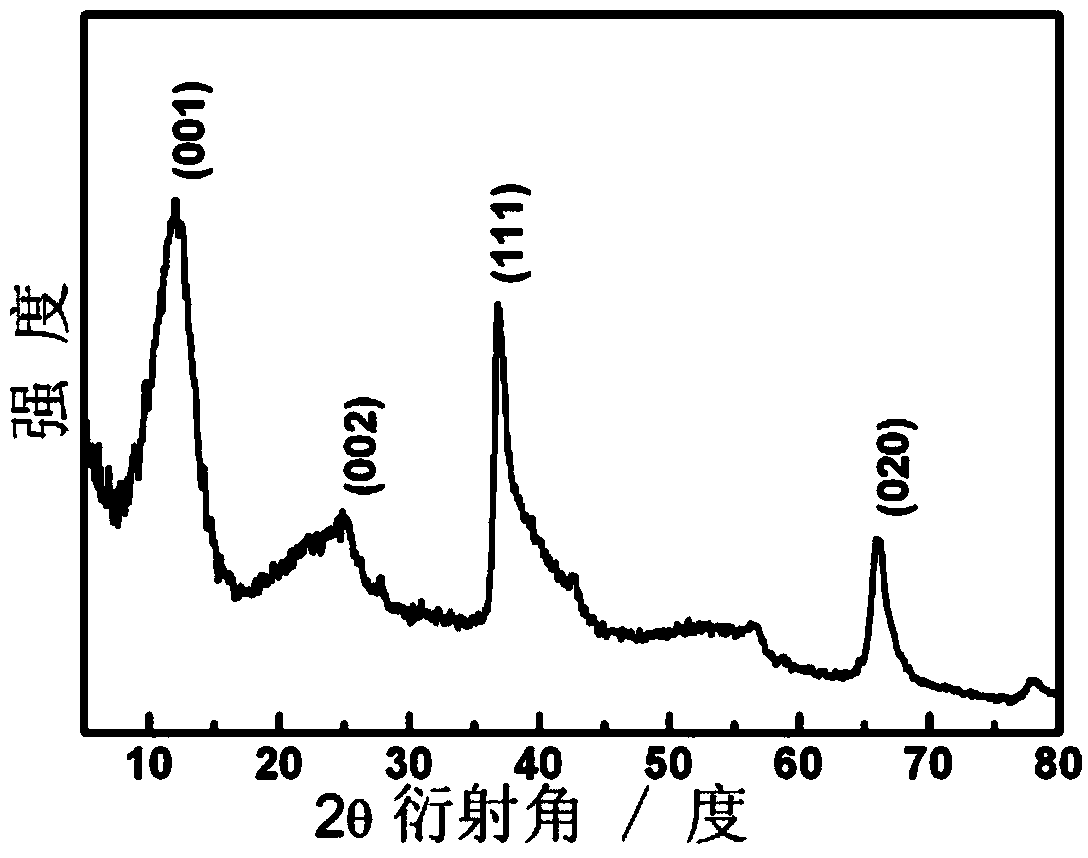

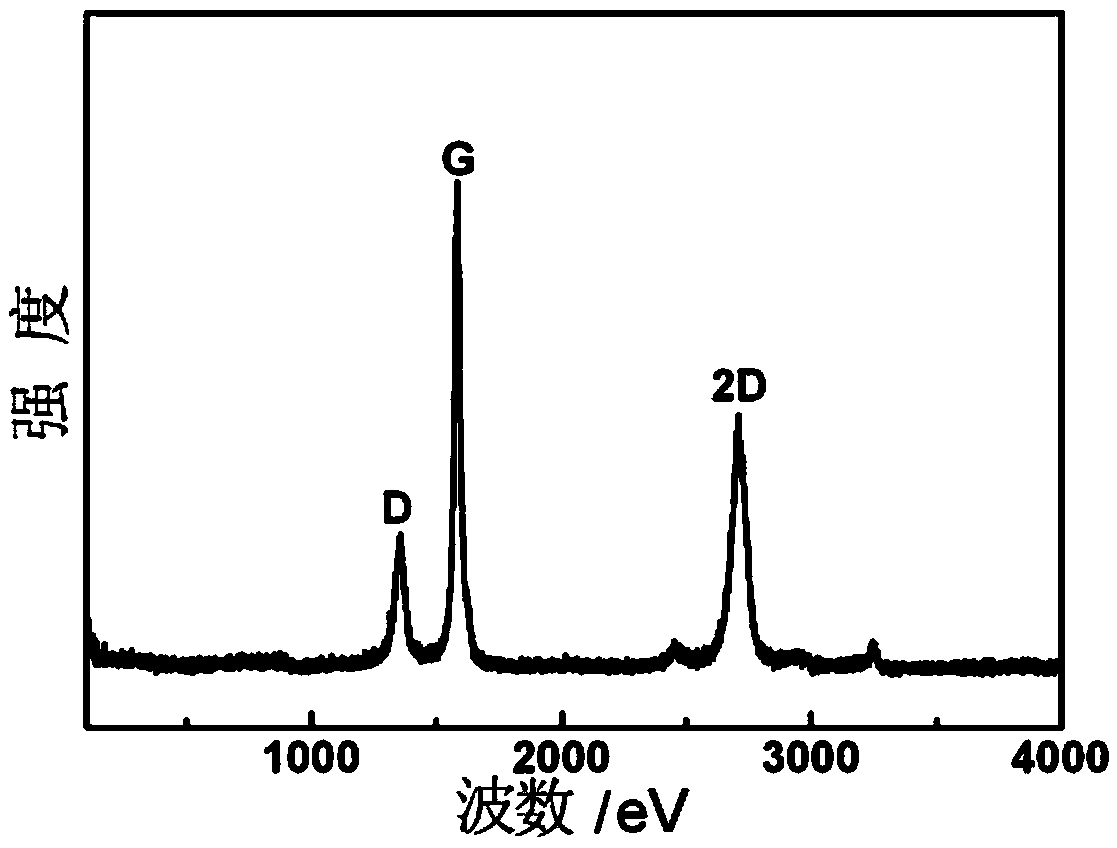

[0040] Put nickel foam into a tube furnace, and raise the temperature to 1000°C at a rate of 100°C / min under an Ar (500s.c.c.m.) atmosphere; after holding for 5 minutes, introduce ethanol into the quartz tube with an Ar (250s.c.c.m.) airflow , reacted for 5 minutes; finally, cooled to room temperature at a cooling rate of 100°C / min in an Ar atmosphere to obtain three-dimensional graphene (Ni / 3D-G) grown on a nickel foam substrate, in which the loading capacity of graphene was 0.85m g / cm 2 ; the KMnO 4 and 96wt%H 2 SO 4 (molar KMnO 4 0.25) dissolved in deionized water, stirred evenly, prepared with K + A solution with a concentration of 0.01mol / L. Use Ni / 3D-G as the matrix, immerse in the above solution, and then transfer it into the reaction kettle, seal it and keep it in an oven at 85°C for 2 hours, then rinse it with deionized water and absolute alcohol several times, and put it in an oven at 60°C Manganese hydroxide loaded on Ni / 3D-G was obtained after vacuum drying ...

Embodiment 2

[0053]Put nickel foam into a tube furnace, and raise the temperature to 1000°C at a rate of 100°C / min under an Ar (500s.c.c.m.) atmosphere; after holding for 5 minutes, introduce ethanol into the quartz tube with an Ar (250s.c.c.m.) airflow , reacted for 3 minutes; finally, cooled to room temperature at a cooling rate of 100°C / min in an Ar atmosphere to obtain three-dimensional graphene (Ni / 3D-G) grown on a nickel foam substrate, in which the loading capacity of graphene was 0.5mg / cm 2 ; the KMnO 4 and 96wt%H 2 SO 4 (molar KMnO 4 0.3) was dissolved in deionized water, stirred well, prepared in K + A solution with a concentration of 0.02mol / L. Use Ni / 3D-G as the matrix, immerse in the above solution, and then transfer it into the reaction kettle. After sealing it, keep it in an oven at 100°C for 1 hour, then rinse it with deionized water and absolute alcohol several times, and put it in an oven at 60°C. After vacuum drying for 12 hours, Ni / 3D-G loaded with manganese hydr...

Embodiment 3

[0058] Put nickel foam into a tube furnace, and raise the temperature to 1000°C at a rate of 100°C / min under an Ar (500s.c.c.m.) atmosphere; after holding for 5 minutes, introduce ethanol into the quartz tube with an Ar (250s.c.c.m.) airflow , reacted for 10 minutes; finally, cooled to room temperature at a cooling rate of 100°C / min under Ar atmosphere to obtain three-dimensional graphene (Ni / 3D-G) grown on a nickel foam substrate, in which the loading capacity of graphene was 1.5mg / cm 2 ; the KMnO 4 and 96wt%H 2 SO 4 (molar KMnO 4 0.5) was dissolved in deionized water, stirred evenly, prepared in K + A solution with a concentration of 0.01mol / L. Use Ni / 3D-G as the matrix, immerse in the above solution, and then transfer it into the reaction kettle, seal it and keep it in an oven at 80°C for 3 hours, then rinse it with deionized water and absolute alcohol several times, and put it in an oven at 60°C Manganese hydroxide loaded on Ni / 3D-G was obtained after vacuum drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com