Artificial articular cartilage material and preparation method thereof

A technology for artificial joints and cartilage, which is applied in the field of chemical modification of hydrogel soft materials, can solve problems such as poor biological activity, mechanical properties that cannot meet the requirements of high stress on articular cartilage, and inability to integrate surrounding tissues, etc., to achieve clear scientific significance, Effects of improving mechanical properties and biological activity and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A kind of preparation method of artificial articular cartilage material of the present invention, comprises the following steps:

[0018] Prepare an aqueous solution of graphene oxide nanosheets,

[0019] uniformly dispersing needle-shaped nano-hydroxyapatite particles with a particle size of 10-1000nm in an aqueous solution of graphene oxide nanosheets to obtain a stable mixed aqueous solution of hydroxyapatite and graphene oxide;

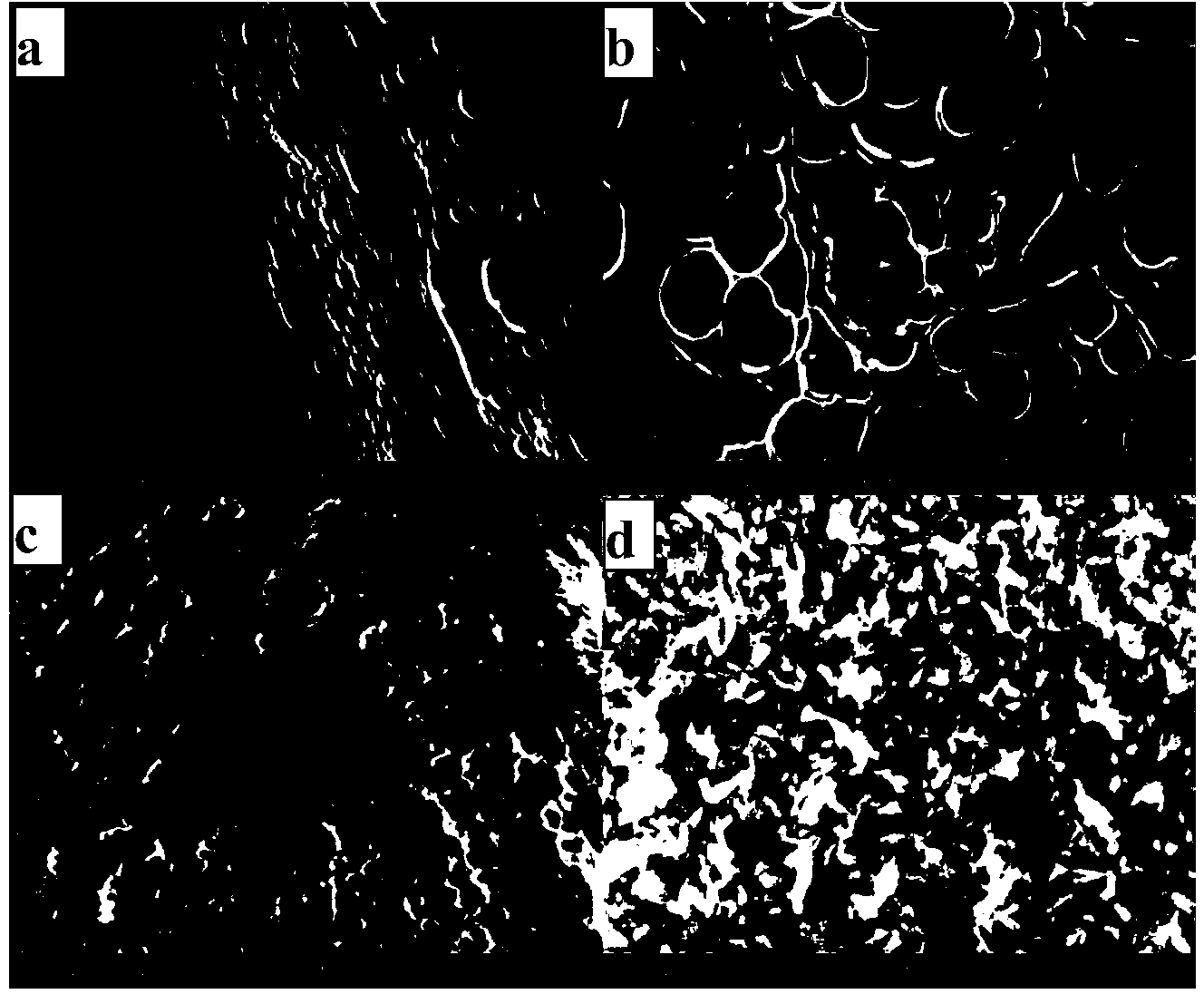

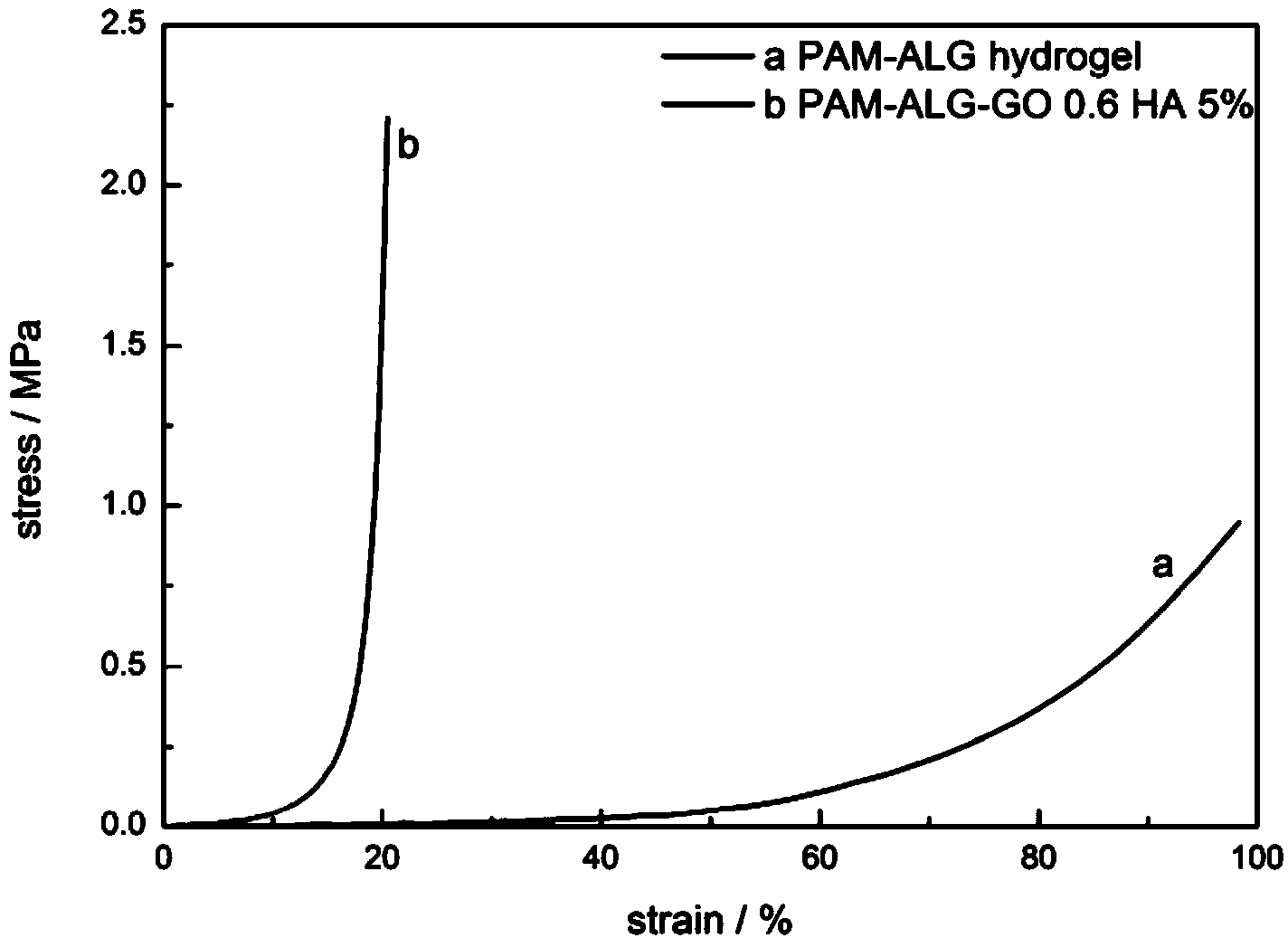

[0020] In an oxygen-free environment, add the raw materials for free radical polymerization to synthesize polyacrylamide and sodium alginate hydrogel in the above mixed aqueous solution in sequence, and after 20-90min, undergo free radical polymerization at a temperature of 30-70°C. Thus, polyacrylamide-sodium alginate-graphene oxide-hydroxyapatite composite hydrogel was obtained.

[0021] The anaerobic protective gas used in the anaerobic protective environment is subject to no reaction with the colloidal solution, and commonly used prote...

Embodiment 1

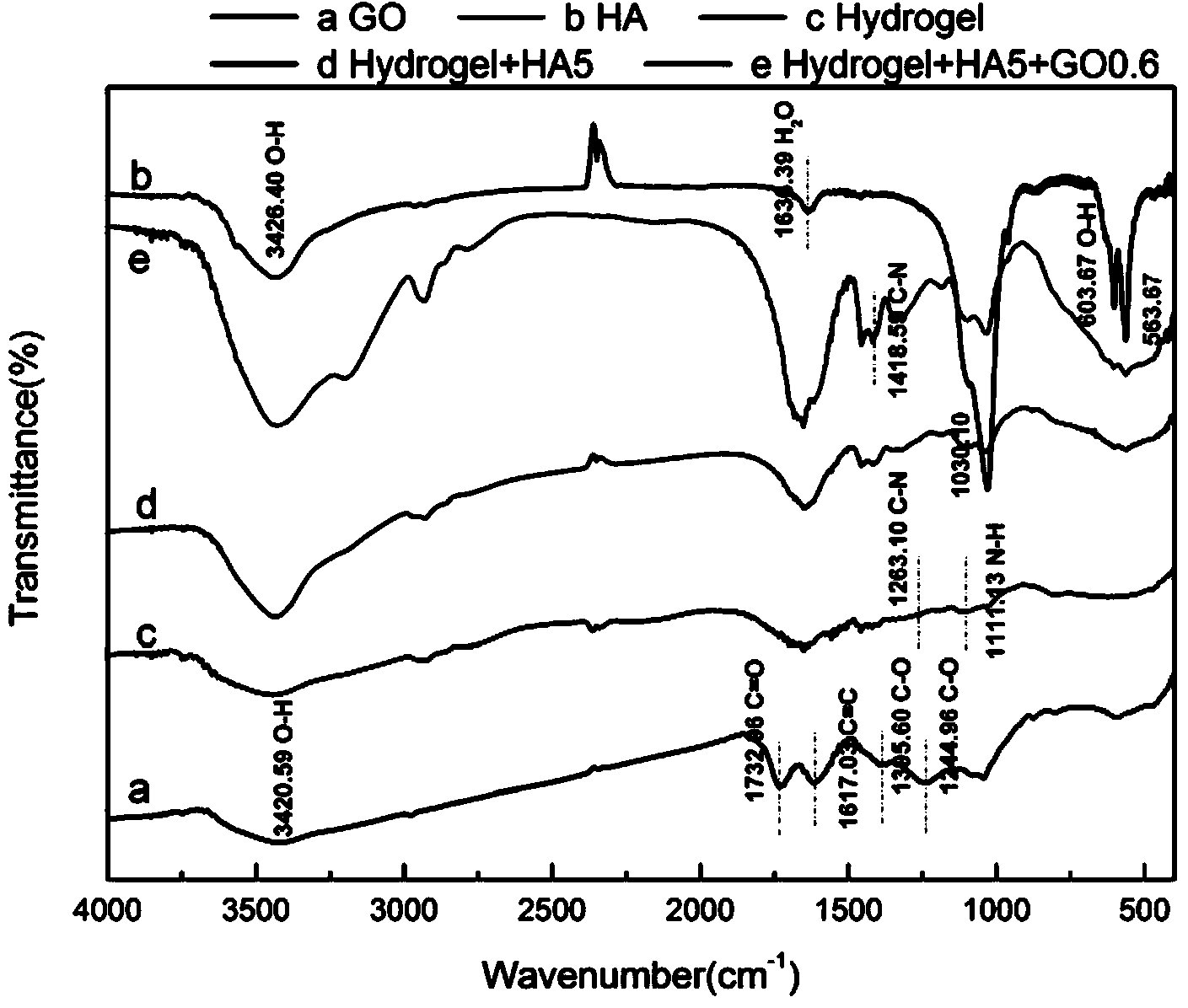

[0024] 1) The aqueous solution of graphene oxide GO nanosheets prepared by the Hummers method was fully ultrasonicated for 1 hour.

[0025] 2) Mechanically blend 5% HA in the 15ml GO nanosheet aqueous solution with a concentration of 2mg / ml above, and ultrasonically oscillate for 30min to ensure that HA is uniformly dispersed in the GO nanosheet aqueous solution.

[0026] 3) In the above mixed solution of GO and HA, under the protective environment of high-purity nitrogen, the raw materials for the synthesis of PAM-ALG hydrogel by free radical polymerization, namely, monomer 1: 5 g of acrylamide; initiator: over Ammonium sulfate 0.015g; covalent bond crosslinking agent: methylenebisacrylamide 0.0031g; catalyst: N,N,N',N',-tetramethyldiacetamide 16μL; ionic bond crosslinking agent: anhydrous chlorine Calcium 0.0661g; monomer 2: sodium alginate 0.5g; dehydrating agent: carbodiimide 0.04g and N-hydroxysuccinimide 0.02g. After 60 min, the PAM-ALG-GO-HA composite hydrogel was prep...

Embodiment 2

[0031] 1) The aqueous solution of graphene oxide GO nanosheets prepared by Brodie method was fully ultrasonicated for 1.5 hours.

[0032] 2) Mechanically blend 3% HA in the 20ml GO nanosheet aqueous solution with a concentration of 0.5mg / ml above, and ultrasonically oscillate for 40min to ensure that HA is uniformly dispersed in the GO nanosheet aqueous solution.

[0033] 3) In the above mixed solution of GO and HA, in the protective environment of high-purity argon, the raw materials for the synthesis of PAM-ALG hydrogel by free radical polymerization, namely, monomer 1: acrylamide; initiator: over Ammonium sulfate 0.015g; covalent bond crosslinking agent: methylenebisacrylamide 0.0031g; catalyst: N,N,N',N',-tetramethyldiacetamide 16μL; ionic bond crosslinking agent: anhydrous chlorine Calcium 0.0661g; monomer 2: sodium alginate 0.6g; dehydrating agent: carbodiimide 0.04g and N-hydroxysuccinimide 0.02g. After 40 min, the PAM-ALG-GO-HA composite hydrogel was prepared by free ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com