Gas atomization preparation method of fine spherical titanium or titanium alloy powder

A titanium alloy and gas atomization technology, which is applied in the field of gas atomization preparation of fine spherical titanium or titanium alloy powder, can solve the problems of oxidation of fine spherical titanium or titanium alloy powder, achieve low cost, prevent powder oxidation, reduce The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

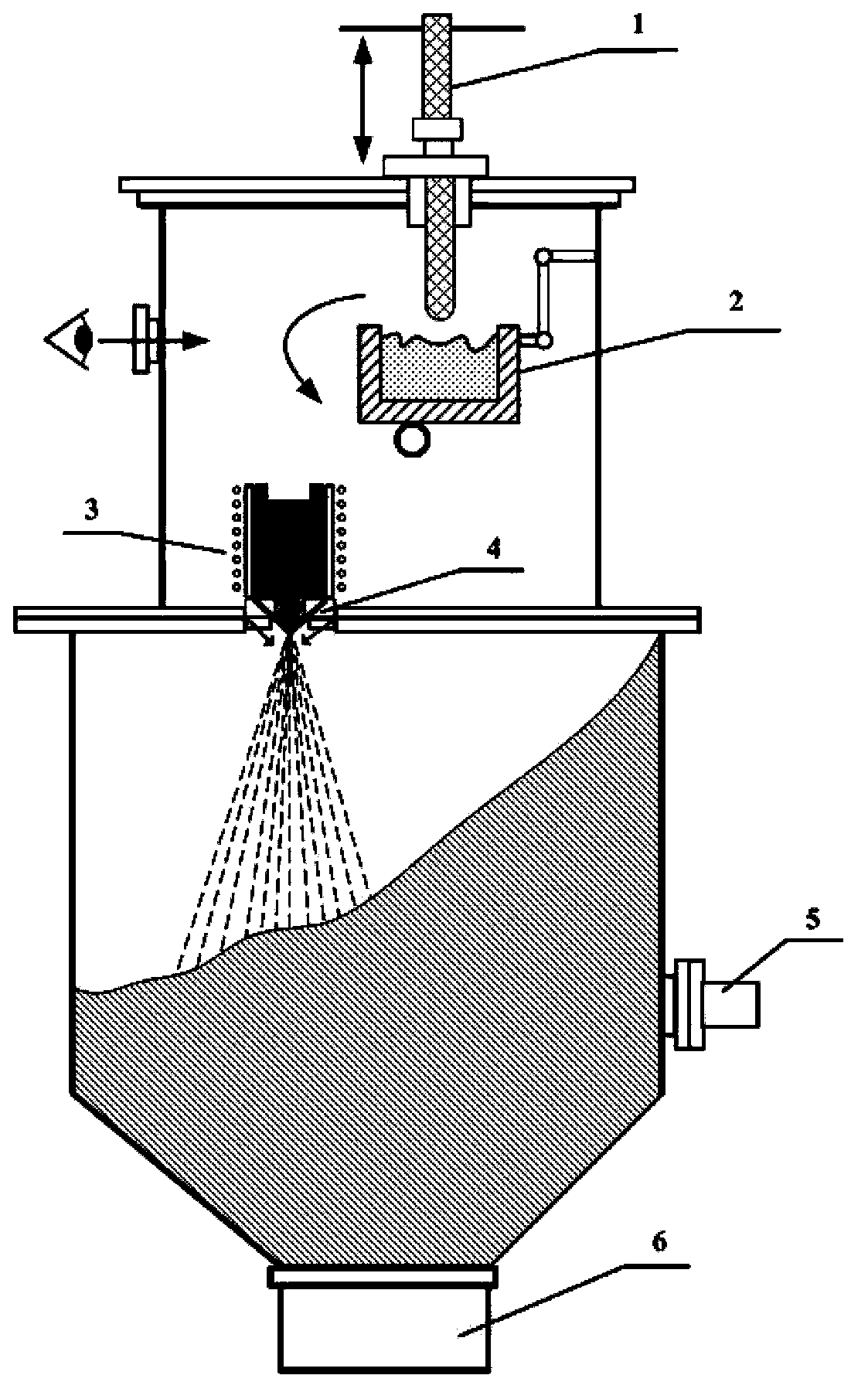

[0030] Preparation of Fine Spherical Ti-6Al-4V Alloy Powders with an Average Particle Size of 45 μm by Gas Atomization

[0031]Sponge titanium, aluminum and vanadium are used as raw materials, and the ingredients are prepared according to the proportion of TC4 (Ti-6Al-4V) alloy. The purity of sponge titanium, aluminum and vanadium is ≥99.9%. Pre-vacuumize the vacuum chamber and melting furnace, and the vacuum degree is 1×10 -4 Pa, filled with high-purity argon for atmosphere protection to prevent oxidation of alloy powder. Use a water-cooled copper crucible for pure melting, the melting temperature is 1650 ° C, and atomization starts after 20 minutes of heat preservation. Double-layer atomizing nozzles are adopted, and high-purity argon gas is used as the atomizing medium to carry out atomization treatment through the main nozzle (tight coupling nozzle), and the atomization pressure is controlled at 1.5~3.5MPa. Hydrogen passes through the secondary nozzle to passivate, cool ...

Embodiment 2

[0033] Preparation of Fine Spherical TC11 Alloy Powder with Average Particle Size of 28 μm by Gas Atomization

[0034] Titanium sponge, aluminum, molybdenum, zirconium, etc. are used as raw materials, and the ingredients are prepared according to TC11 (Ti-6Al-3.5Mo-1.8Zr) alloy. The purity of titanium sponge, aluminum, molybdenum, and zirconium is ≥99.9%. Pre-vacuumize the vacuum chamber and melting furnace, and the vacuum degree is 1×10 -4 Pa, filled with high-purity helium for atmosphere protection to prevent oxidation of alloy powder. The alloy powder is purely smelted in a water-cooled copper crucible, the melting temperature is 1550°C, and the atomization treatment is carried out after 60 minutes of heat preservation for full alloying. Double-layer atomizing nozzles are adopted, and high-purity helium is used as the atomizing medium to carry out atomization treatment through close-coupled nozzles, and the atomization pressure is controlled at 6.0~7.0MPa. Hydrogen passes...

Embodiment 3

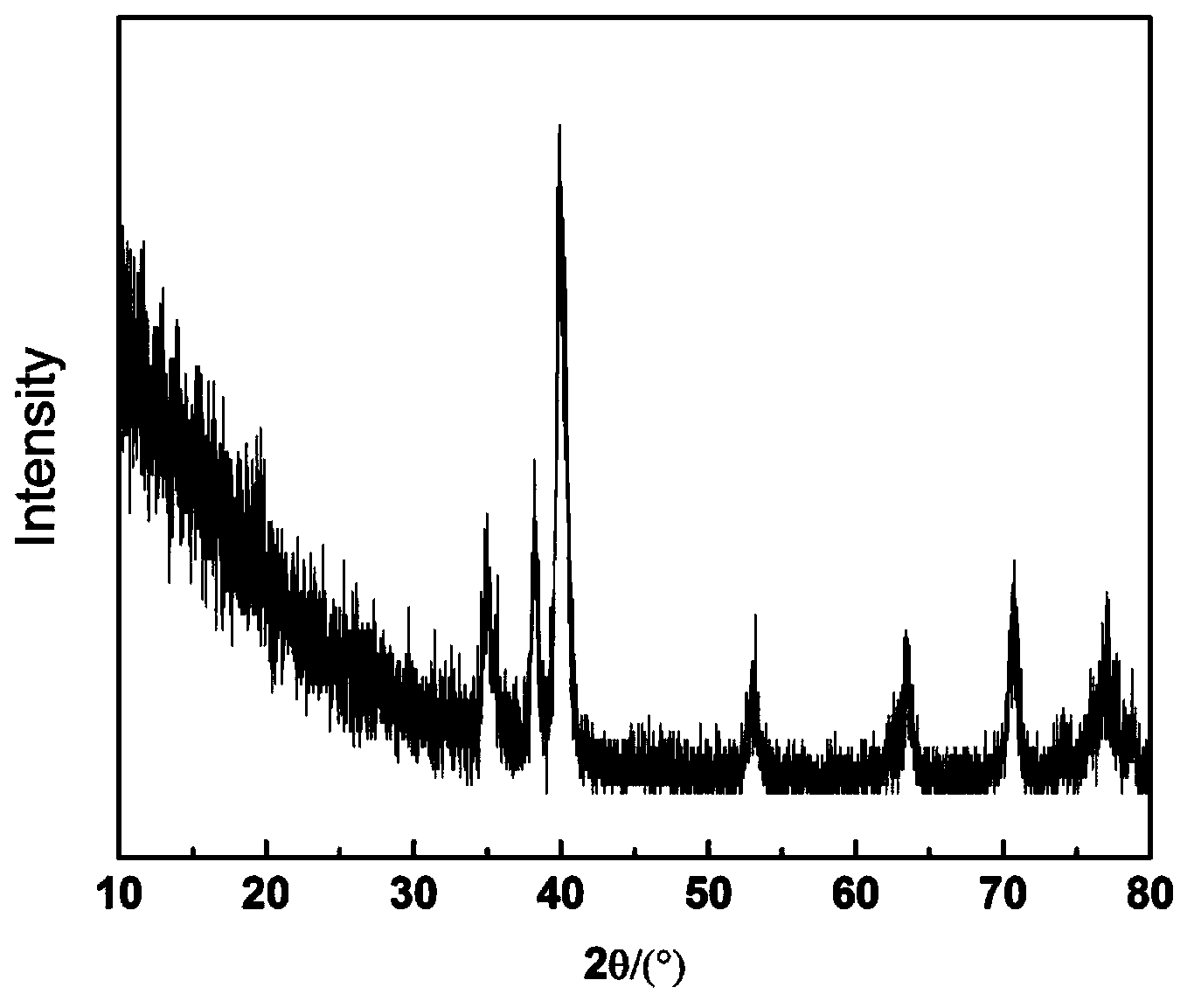

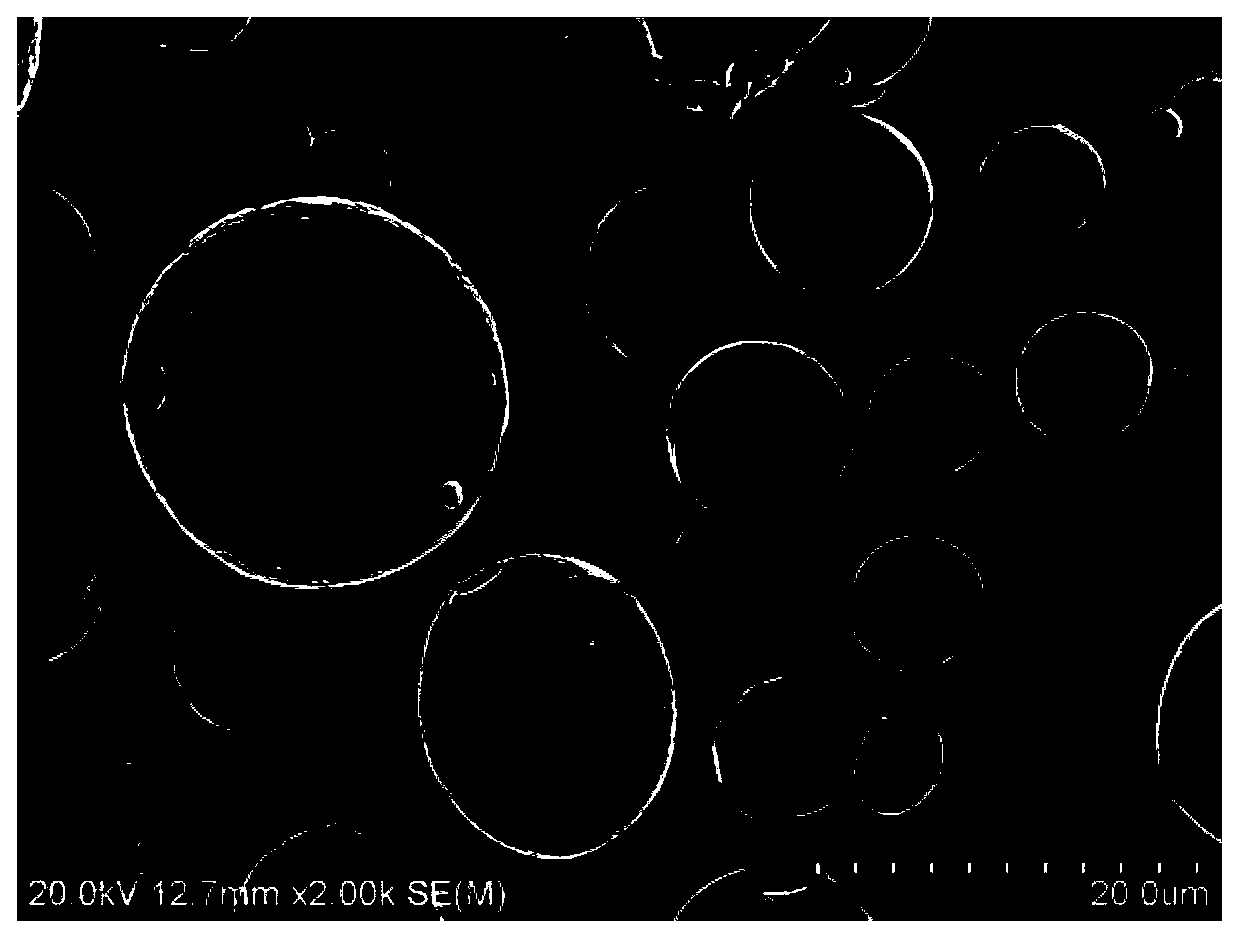

[0036] Preparation of fine spherical titanium powder with an average particle size of 10 μm by gas atomization

[0037] Made of titanium sponge, the purity is ≥99.9%. Pre-vacuumize the vacuum chamber and melting furnace, and the vacuum degree is 1×10 -4 Pa, filled with high-purity argon for atmosphere protection to prevent powder oxidation. Use a water-cooled copper crucible for pure melting, the melting temperature is 1700 ° C, and atomization starts after 45 minutes of heat preservation. Double-layer atomizing nozzles are adopted, and high-purity argon gas is used as the atomizing medium for atomization treatment through close-coupled nozzles, and the atomization pressure is controlled at 6.5~9.5MPa. Hydrogen passes through the secondary nozzle to forcibly passivate, cool and disperse the molten droplets, and the atomization pressure is controlled at 1.5MPa. The powder is collected by cyclone separation and the powder is sieved and vacuum packed. According to the test an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com