Chitosan/in-situ amphoteric silicon-titanium hybrid film and its preparation method and application

A chitosan and hybrid membrane technology, which is applied in the field of chitosan/in-situ amphoteric silicon-titanium hybrid membrane and its preparation, can solve the problem that proton exchange membrane has not been reported in the literature, and achieves prevention of agglomeration, low methanol The effect of permeability and process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

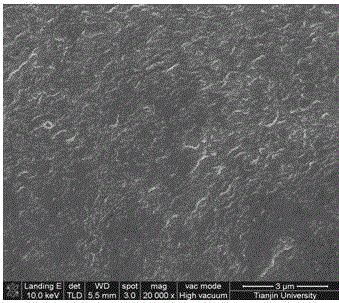

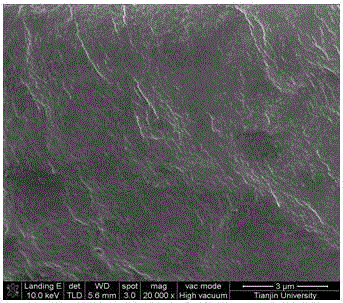

Image

Examples

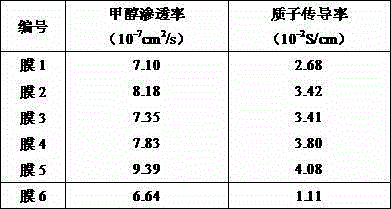

Embodiment 1

[0017] Weigh 1g with a molecular weight of 6×10 5 , the degree of deacetylation is 91% chitosan dissolved in 25g mass concentration of 2% acetic acid aqueous solution, at 70 oC Stir for complete dissolution. At room temperature, 0.0355g of ethyl orthosilicate was added to 5g of aqueous hydrochloric acid with a mass concentration of 7%, and hydrolyzed at 45°C for 2h. Add 0.0323g of titanium tetrachloride to 5g of 20% ethanol aqueous solution by mass fraction, and hydrolyze for 2h at room temperature. After mixing the two, the reaction was stirred at room temperature for 3h. Then add 0.0032g of 3,4-dihydroxyphenylpropionic acid and place it at room temperature for chelation reaction for 1h. Continue to add 0.0037g of 3-aminopropyltrimethoxysiloxane and react in a water bath at 60°C for 4 hours to obtain a maroon amphoteric inorganic silicon-titanium sol solution. Slowly add the maroon amphoteric inorganic silicon-titanium sol solution into the chitosan solution, stir at room...

Embodiment 2

[0019] Weigh 1g with a molecular weight of 6×10 5 , the degree of deacetylation is 91% chitosan dissolved in 50g mass concentration of 2% acetic acid aqueous solution, at 75 oC Stir for complete dissolution. At room temperature, 0.0828g of ethyl orthosilicate was added to 5g of aqueous hydrochloric acid solution with a mass concentration of 5%, and hydrolyzed at 30°C for 2h. Add 0.0754g of titanium tetrachloride to 5g of 50% ethanol aqueous solution, and hydrolyze at room temperature for 2h. After mixing the two, the reaction was stirred at room temperature for 3.5h. Then add 0.0061g of 3,4-dihydroxyphenylpropionic acid and place it at room temperature for chelation reaction for 1h. Continue to add 0.0086g of 3-aminopropyltrimethoxysiloxane and react in a water bath at 45°C for 5h to obtain a maroon amphoteric inorganic silicon-titanium sol solution. Slowly add the maroon amphoteric inorganic silicon-titanium sol solution into the chitosan solution, stir at room temperatur...

Embodiment 3

[0021] Weigh 1g with a molecular weight of 6×10 5 , the degree of deacetylation is 91% of chitosan dissolved in 30g mass concentration of 2% acetic acid aqueous solution, at 80 o C for complete dissolution. At room temperature, 0.0524g of ethyl orthosilicate was added to 5g of aqueous hydrochloric acid solution with a mass concentration of 5%, and hydrolyzed at 60°C for 2h. Add 0.0239g of titanium tetrachloride to 5g of 30% ethanol aqueous solution, and hydrolyze at room temperature for 2h. After mixing the two, the reaction was stirred at room temperature for 4h. Then add 0.0025g of 3,4-dihydroxyphenylpropionic acid and place it at room temperature for chelation reaction for 1h. Continue to add 0.0068g of 3-aminopropyltrimethoxysiloxane and react in a water bath at 30°C for 5h to obtain a maroon amphoteric inorganic silicon-titanium sol solution. Slowly add the maroon amphoteric inorganic silicon-titanium sol solution into the chitosan solution, stir at room temperature f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com