Preparation method of oil/water separation material

A technology of oil-water separation and template method, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of complex operation, membrane fouling, and high cost, and achieve the effects of simple operation, controllable experimental parameters, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific Embodiments 1. In this embodiment, a superhydrophobic reticular porous film is prepared according to the following steps:

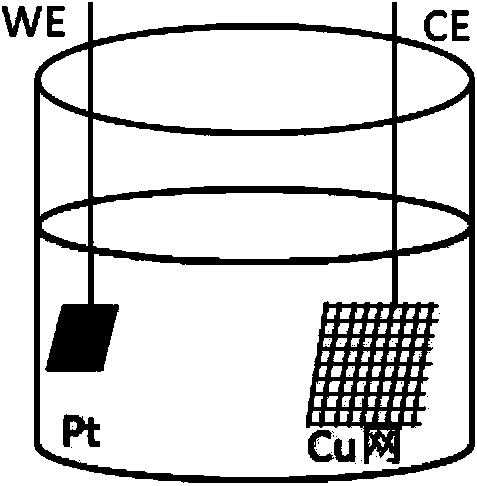

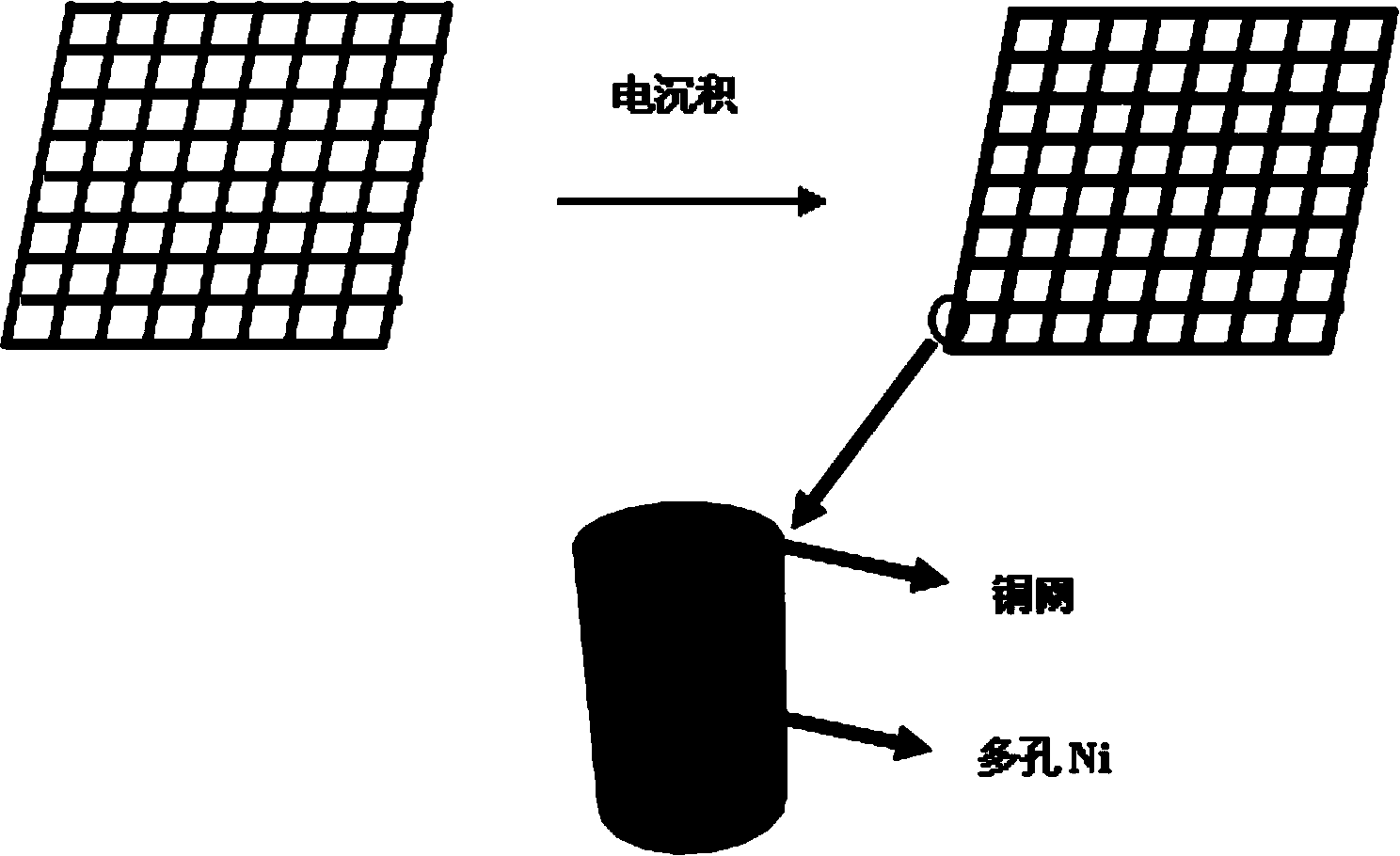

[0023] The first step, the preparation of mesh porous Ni film by hydrogen bubble template method ( figure 2 )

[0024] Electrodeposited mesh porous Ni thin films by hydrogen bubble template method are based on platinum sheet (1cm 2 ) as the anode, and the counter electrode uses copper mesh (aperture 300μm, area 3*3cm 3 ) is the cathode, and its electroplating device such as figure 1 shown. The pretreatment of the copper mesh in the experiment includes polishing, degreasing, acid etching, water washing, absolute ethanol soaking, acetone cleaning, and low-temperature blast drying. The composition of the plating solution is 0.01-0.2mol L -1 NiCl 2 and 0.2-2mol L -1 NH 4 Cl, pH is controlled within the range of 4.0±0.5, and the current density range of electrodeposition is 0.1-6.0A cm -2 , the deposition time is 10-40s. By adjusting...

specific Embodiment approach 2

[0028] Specific embodiment two: In this embodiment, a superhydrophobic mesh porous film is prepared according to the following steps:

[0029] Step 1. Preparation of mesh-like porous Ni film by hydrogen bubble template method

[0030] Electrodeposited mesh porous Ni thin films by hydrogen bubble template method are based on platinum sheet (1cm 2 ) as the anode, and the counter electrode uses copper mesh (aperture 300μm, area 3*3cm 2 ) is the cathode. The pretreatment of the copper mesh in the experiment includes polishing, degreasing, acid etching, water washing, absolute ethanol soaking, acetone cleaning, and low-temperature blast drying. The composition of the plating solution is 0.2mol L -1 NiCl 2 and 0.5mol·L -1 NH 4 Cl, pH is controlled within the range of 4.0±0.5, and the current density of electrodeposition is 0.5A cm -2 , the deposition time is 30s. By adjusting the deposition parameters such as current density, deposition time, bath composition, etc., the stru...

specific Embodiment approach 3

[0034] Specific embodiment three: In this embodiment, a superhydrophobic reticulated porous film is prepared according to the following steps:

[0035] Step 1. Preparation of mesh-like porous Ni film by hydrogen bubble template method

[0036] Hydrogen bubble template electrodeposition network porous Ni thin film is to use platinum sheet (1cm2) as anode, copper mesh (aperture 300μm, diameter 3cm) is used as cathode for counter electrode. The pretreatment of the copper mesh in the experiment includes polishing, degreasing, acid etching, water washing, absolute ethanol soaking, acetone cleaning, and low-temperature blast drying. The composition of the plating solution is 0.2mol L -1 NiCl 2 and 2mol L -1 NH 4 Cl, pH is controlled within the range of 4.0±0.5, and the current density of electrodeposition is 0.5A cm -2 , the deposition time is 30s. The deposited net film should be immediately rinsed with distilled water, soaked in absolute ethanol and then dried to obtain a ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com