Composition for improving ignition temperature of plastic glowing filament as well as preparation method and application thereof

A technology of glow wire and composition, which is applied in the field of composition for increasing the ignition temperature of plastic glow wire and its preparation, can solve the problems of affecting mechanical properties and processing performance, limiting design space, increasing costs, etc., and achieves good heat insulation effect, The formation speed is fast, and the effect of the process is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

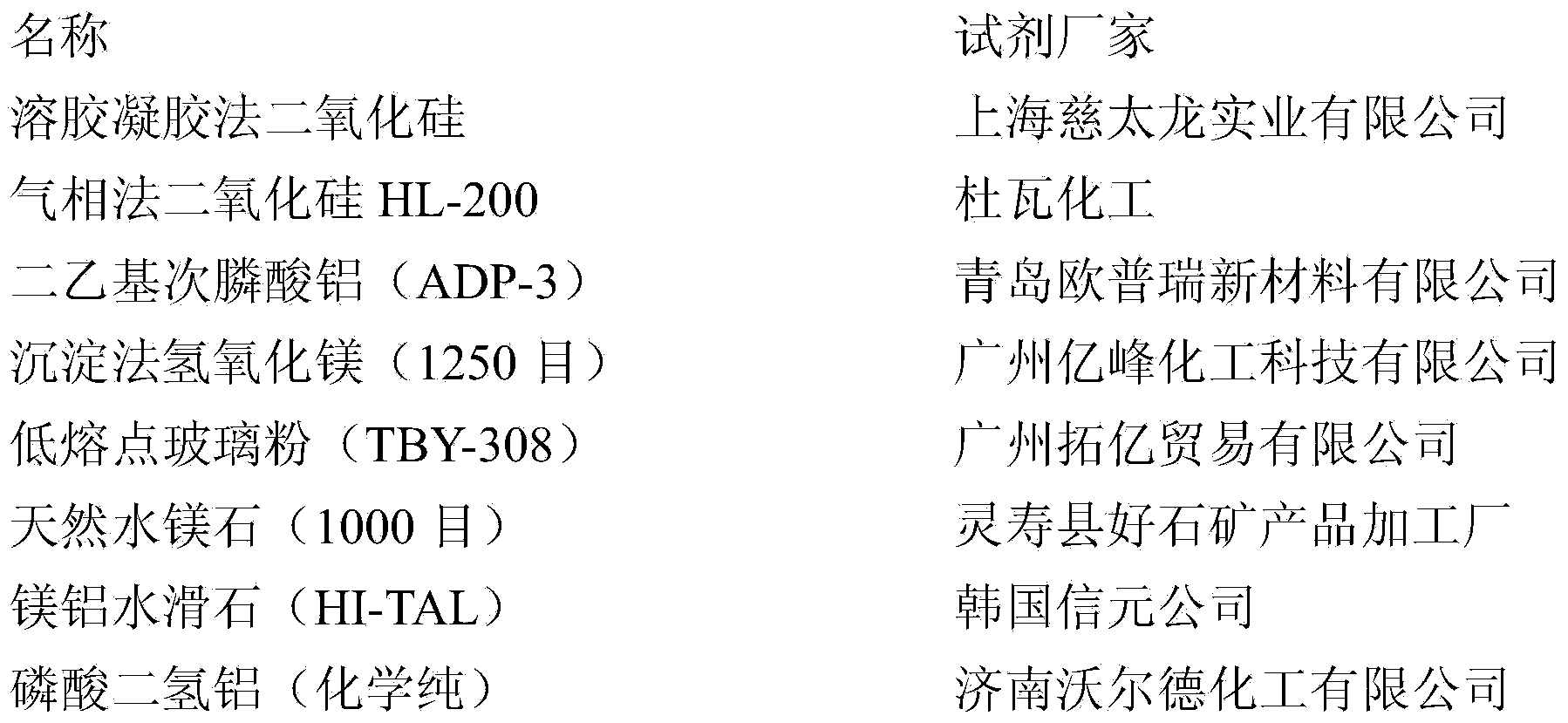

[0055] (1) Prepare 10 parts by mass of sol-gel silica and ethanol to form a silica dispersion with a mass concentration of 20%;

[0056] (2) Add 100 parts by mass of aluminum diethylphosphinate into a high-speed mixer, add 41.65 parts by mass of silica dispersion in batches under high-speed stirring at 5000 rpm, mix uniformly for 5 minutes, and then vacuum dry at 60°C 2h removes solvent, obtains the mixture of aluminum diethylphosphinate and silicon dioxide;

[0057] (3) Add 20 parts by mass of magnesium hydroxide by precipitation method into a high-speed mixer, add 8.35 parts by mass of silica dispersion in batches under high-speed stirring at 5000 rpm, mix uniformly for 5 minutes, and then vacuum dry at 60°C for 2 hours to remove Solvent, obtains the mixture of magnesium hydroxide and silicon dioxide;

[0058] (4) The mixture of aluminum diethylphosphinate and silicon dioxide obtained in step (2) and the mixture of magnesium hydroxide and silicon dioxide obtained in step (3...

Embodiment 2

[0061] (1) 50 parts by mass of glass powder with a low melting point and acetone are formulated into a glass powder dispersion with a mass concentration of 20%;

[0062] (2) Add 100 parts by mass of aluminum methyl ethyl phosphinate into a high-speed mixer, add 138.89 parts by mass of glass powder dispersion in batches under high-speed stirring at 6000 rpm, mix evenly for 10 minutes, and then vacuum dry at 100°C 1h removes solvent, obtains the mixture of aluminum methyl ethyl phosphinate and glass powder;

[0063] (3) Add 80 parts by mass of natural brucite into a high-speed mixer, add 111.11 parts by mass of glass powder dispersion in batches under high-speed stirring at 6000 rpm, mix uniformly for 10 minutes, and then vacuum dry at 100°C for 1 hour to remove the solvent. A mixture of natural brucite and glass powder is obtained;

[0064] (4) The mixture of aluminum methyl ethyl phosphinate and glass powder obtained in step (2) and the mixture of natural brucite and glass po...

Embodiment 3

[0067] (1) Prepare 30 parts by mass of fumed silica and ethanol to form a silica dispersion with a mass concentration of 20%;

[0068] (2) Add 100 parts by mass of aluminum dihydrogen phosphate into a high-speed mixer, add 100 parts by mass of silicon dioxide dispersion in batches under high-speed stirring at 7000 rpm, mix uniformly for 15 minutes, and then vacuum dry at 120°C for 0.5 hours to remove Solvent, obtains the mixture of aluminum dihydrogen phosphate and silicon dioxide;

[0069] (3) Add 50 parts by mass of magnesium aluminum hydrotalcite into a high-speed mixer, add 50 parts by mass of silica dispersion in batches under high-speed stirring at 7000 rpm, mix uniformly for 15 minutes, and then vacuum dry at 120°C for 0.5 hours to remove Solvent, obtains the mixture of magnesium aluminum hydrotalcite and silicon dioxide;

[0070] (4) Mix the mixture of aluminum dihydrogen phosphate and silicon dioxide obtained in step (2) with the mixture of magnesium aluminum hydrota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com